- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V,220V,380V,460V

-

Power:

-

80KW

-

Dimension(L*W*H):

-

100*60*80cm

-

Weight (KG):

-

300

-

After Warranty Service:

-

Video Technical Support Online Support

Quick Details

-

Machine Type:

-

polyethylene powder coating machine, Spray Booths, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Coating Equipment, Sandblasting Machine, surface coating machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SX

-

Voltage:

-

110V,220V,380V,460V

-

Power:

-

80KW

-

Dimension(L*W*H):

-

100*60*80cm

-

Weight (KG):

-

300

-

After Warranty Service:

-

Video Technical Support Online Support

Brief Introduction

SX6018

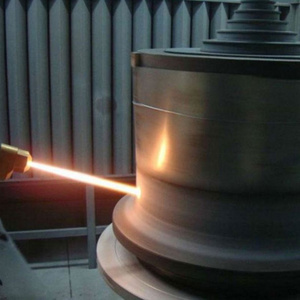

is kind of flame plastic spraying equipment ,our company has improved the design on the basis of flame spray equipment of France SNMI company and British SCHORI company.It can spray all kind of thermosetting plastic powders, such as polyethylene (PE), nylon, polyolefin (PO), etc.

1.Construction of SX-6018 power flame plastic spray equipment

SX6018 plasticpowderspray equipment consists of plastic spraying gun, powder feeder, pipeline and gas path regulator. The user

only should prepare air compressor with 0.9 m3 / min , oxygen, acetylene gas,decompression table of oxygen acetylene , line pipe.

2. Principle of SX-6018 power flame plastic spray equipment

SX6018 power plastic spray equipment adapts the special powder feeder hose to send powder and flame by plastic gun, produce heat source with the aid of oxyacetylene, compress air jets of gas to protect flame flow,heat spraying plastic powder to melt plastic state or condition, spraying the surface after pretreatment ,

3.parameters of SX6018 plastic powder coating machine

4. Characteristic of SX-6018 power flame plastic spray equipment

Plastic powder Flame spraying machine mainly used to spray plastic on large-scale corrosion resistant live project . The

characteristic is that the coating layer is thick , operation is simple, the equipment is easy to carry, and can be used for site

construction.

compared to electrostatic powder coating and fluidized bed coating, the plastic powder coating machine are of advantages below:

(1 )The cost of equipment is low, without special spraying room, drying room.

(2) Portable and easy to carry, can be on-site construction, spraying process can not be limited by workpiece size and shape.

(3) can work in 100% relative humidity, low temperature environmental conditions

(4) Powder coating materials do not contain solvents, do not need drying curing time after spraying.

(5) can spray a variety of substrate materials such as steel, concrete and so on.

(6) coating layer can be repaired, for the small defect part, as long as you heat the surface then it can be repaired, for large

defect part,you can re-spray and repair it.

(7 )easy to change powder and color

5. the application range of SX-6018 power flame plastic spray equipment

Can directly spray all kinds of plastic coating of acid, alkali, salt , no need the heat curing device, especially suitable for

the scene of large area flame plastic spraying construction, in the aspect of anti-corrosion performance, operating technology and operating environment ,it can take place of heavy anti-corrosion coating and glass steel lining.

6. Application Examples of SX-6018 power flame plastic spray equipment

(1) Resistant to various corrosive media containers: liquor, beer, milk, salt, food, sewage treatment equipment, power plant steel desalting water tank, including ultrafiltration water tank, first-level freshwater box, two-class freshwater tank, water tank and other anti-corrosion, using the United States imported EAA plastic powder large Area Flame Spray site construction.

(2) All kinds of steel structure anti-corrosion, decoration, insulation, wear-resistant, antifriction: petrochemical, power plant

large storage tanks and west-East gas pipeline two-layer PE and three-layer PE anti-corrosion pipe welded joints On-site repair, highway guardrail, municipal lighting pole, stadium grid engineering, water pumps, chemical fan, printing press nylon drum, car spline shaft, Electroplating hanging fixture and so on

(3)Marine steel structure and harbor Facilities: Bridge Foundation, Breakwater, Banqiao, steel pipe pile, plate pile, trestle,

buoy, etc. to prevent seawater corrosion.

1.Construction of SX-6018 power flame plastic spray equipment

SX6018 plasticpowderspray equipment consists of plastic spraying gun, powder feeder, pipeline and gas path regulator. The user

only should prepare air compressor with 0.9 m3 / min , oxygen, acetylene gas,decompression table of oxygen acetylene , line pipe.

2. Principle of SX-6018 power flame plastic spray equipment

SX6018 power plastic spray equipment adapts the special powder feeder hose to send powder and flame by plastic gun, produce heat source with the aid of oxyacetylene, compress air jets of gas to protect flame flow,heat spraying plastic powder to melt plastic state or condition, spraying the surface after pretreatment ,

3.parameters of SX6018 plastic powder coating machine

4. Characteristic of SX-6018 power flame plastic spray equipment

Plastic powder Flame spraying machine mainly used to spray plastic on large-scale corrosion resistant live project . The

characteristic is that the coating layer is thick , operation is simple, the equipment is easy to carry, and can be used for site

construction.

compared to electrostatic powder coating and fluidized bed coating, the plastic powder coating machine are of advantages below:

(1 )The cost of equipment is low, without special spraying room, drying room.

(2) Portable and easy to carry, can be on-site construction, spraying process can not be limited by workpiece size and shape.

(3) can work in 100% relative humidity, low temperature environmental conditions

(4) Powder coating materials do not contain solvents, do not need drying curing time after spraying.

(5) can spray a variety of substrate materials such as steel, concrete and so on.

(6) coating layer can be repaired, for the small defect part, as long as you heat the surface then it can be repaired, for large

defect part,you can re-spray and repair it.

(7 )easy to change powder and color

5. the application range of SX-6018 power flame plastic spray equipment

Can directly spray all kinds of plastic coating of acid, alkali, salt , no need the heat curing device, especially suitable for

the scene of large area flame plastic spraying construction, in the aspect of anti-corrosion performance, operating technology and operating environment ,it can take place of heavy anti-corrosion coating and glass steel lining.

6. Application Examples of SX-6018 power flame plastic spray equipment

(1) Resistant to various corrosive media containers: liquor, beer, milk, salt, food, sewage treatment equipment, power plant steel desalting water tank, including ultrafiltration water tank, first-level freshwater box, two-class freshwater tank, water tank and other anti-corrosion, using the United States imported EAA plastic powder large Area Flame Spray site construction.

(2) All kinds of steel structure anti-corrosion, decoration, insulation, wear-resistant, antifriction: petrochemical, power plant

large storage tanks and west-East gas pipeline two-layer PE and three-layer PE anti-corrosion pipe welded joints On-site repair, highway guardrail, municipal lighting pole, stadium grid engineering, water pumps, chemical fan, printing press nylon drum, car spline shaft, Electroplating hanging fixture and so on

(3)Marine steel structure and harbor Facilities: Bridge Foundation, Breakwater, Banqiao, steel pipe pile, plate pile, trestle,

buoy, etc. to prevent seawater corrosion.

Other main thermal spraying equipment and service:

(1) Vacuum plasma spray machine

(2) Thermal spray coating services

(3) HVOF spray equipment

(4) Plasma spray equipment

(5) Arc spray equipment

(6) Sputter Target Produce Equipment and technology

(7) Industrial water chillers

(8) Precious metal vacuum coating equipment

(9) Cooker magnetism and thermal conduction coating spraying production line

(10) Electro Brush Plating Equipment

(11) High power flame plastic spray equipment

(12) Arc spray wires (Zinc wire, Aluminum wire, copper wire, NiAl alloy wire, brass wire, etc)

(13) Thermal spray powder (Al2O3, Cr2O3, TiO2, ZrO2, WC-Co, CrCo-NiCr, etc)

(1) Vacuum plasma spray machine

(2) Thermal spray coating services

(3) HVOF spray equipment

(4) Plasma spray equipment

(5) Arc spray equipment

(6) Sputter Target Produce Equipment and technology

(7) Industrial water chillers

(8) Precious metal vacuum coating equipment

(9) Cooker magnetism and thermal conduction coating spraying production line

(10) Electro Brush Plating Equipment

(11) High power flame plastic spray equipment

(12) Arc spray wires (Zinc wire, Aluminum wire, copper wire, NiAl alloy wire, brass wire, etc)

(13) Thermal spray powder (Al2O3, Cr2O3, TiO2, ZrO2, WC-Co, CrCo-NiCr, etc)

Exhibition

Certifications

Clients

Product packaging

Our machines are very professional ,in order to help you get the best solution ,please kindly reply the following technical questions.

1.What kind of product will you want to spray ? --- Could you provide some pictures?

2. What is the working conditions for your product ? --- What is the PH and temperature ?

3. What kind of material will you want to use? --- aluminum wire,zinc wire or tungsten carbide powder ,ceramic powder or some others?

4. Which effect will you want to get ? --- high temperature resisting ,wear resisting or anti corrosion ,repairing work or others?

5. Do you have any other technical requirements? --- the more the better

1.What kind of product will you want to spray ? --- Could you provide some pictures?

2. What is the working conditions for your product ? --- What is the PH and temperature ?

3. What kind of material will you want to use? --- aluminum wire,zinc wire or tungsten carbide powder ,ceramic powder or some others?

4. Which effect will you want to get ? --- high temperature resisting ,wear resisting or anti corrosion ,repairing work or others?

5. Do you have any other technical requirements? --- the more the better

Hot Searches