- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

2000 kN

-

Place of Origin:

-

Henan, China

-

Year:

-

2024

-

Voltage:

-

220v/380v/415v

-

Weight (T):

-

2 T

-

Model Number:

-

200/315

-

Motor Power (kw):

-

15 kw

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Hydraulic Press Machine

-

Keyword:

-

Hydryalic Press

-

Function:

-

Automatic

-

Usage:

-

Pressing Metal Sheet

-

Application:

-

Widely

-

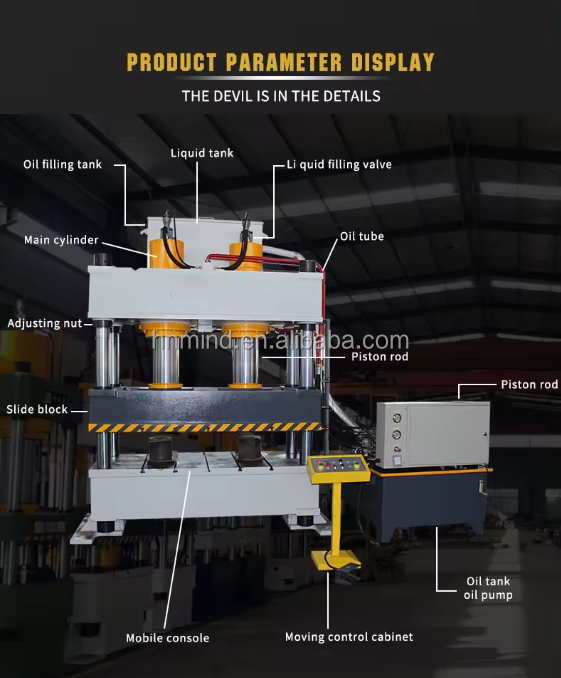

Type:

-

Four Columns

-

Color:

-

Costomized

-

Advantage:

-

High Efficiency Hydraulic Press Machine

-

Item:

-

100/150/200/250/315/350/400/500 Ton

-

Key Words:

-

Molding Hydraulic Press Machine

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

500, 600, 800, 900

-

Ejector Force (kN):

-

20/30/50

-

Return Force (kN):

-

2000 kN

-

Place of Origin:

-

Henan, China

-

Year:

-

2024

-

Voltage:

-

220v/380v/415v

-

Weight (T):

-

2 T

-

Model Number:

-

200/315

-

Motor Power (kw):

-

15 kw

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Hydraulic Press Machine

-

Keyword:

-

Hydryalic Press

-

Function:

-

Automatic

-

Usage:

-

Pressing Metal Sheet

-

Application:

-

Widely

-

Type:

-

Four Columns

-

Color:

-

Costomized

-

Advantage:

-

High Efficiency Hydraulic Press Machine

-

Item:

-

100/150/200/250/315/350/400/500 Ton

-

Key Words:

-

Molding Hydraulic Press Machine

Product Description

Hydraulic Press Machine

Features:

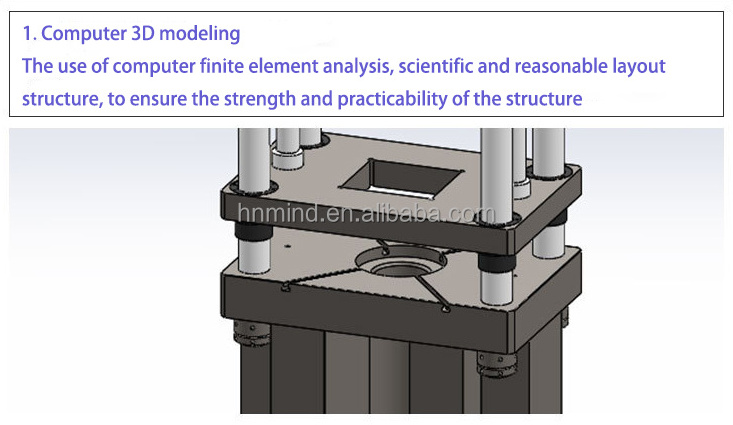

1. Computer optimize 3-beam, 4- column structure, simple but with high performance ratio.

2. Catridge valve intergral unit equipped for hydraulic control system, reliable, durable and less hydraulic shock, with shorter connection pipeline and fewer releases points.

3. Independent electrial control, reliable, audio-visual and convenient for maintenance.

4. Centralized button control system, with adjustment, hand semi auto operation modes at operator's choice.

5. Fixed stroke forming process or fixed pressure forming process selected through control panel, with pressure hold and time delay functions.

6. The machine has a rail automatic lubrication device.

7. The operating force, no load traveling and low speed movement and travel range can be adjusted subjuce to technological requirements.

8. The stroke and pressure can be adjusted within specific range.

Products Description

Main Features:

Specification

|

Model

|

63t-Z

|

100t-A-Z

|

200T-A-Z

|

315T-A-Z

|

315T-A-Z

|

1000T

|

|

Maximum liquid pressure MPa

|

25

|

25

|

25

|

25

|

25

|

25

|

|

Slide stroke mm

|

400

|

500

|

500

|

500

|

600

|

900

|

|

Maximum opening height mm

|

700

|

800

|

900

|

900

|

1000

|

1500

|

|

Table size mm

|

520X520

|

700*620

|

800*800

|

800*800

|

1000*1000

|

1500*1500

|

|

Low speed mm/s

|

150

|

190

|

190

|

160

|

100

|

120

|

|

Working speed mm/s

|

15-22

|

16-24

|

12-18

|

6-12

|

6-15

|

6-12

|

|

Backhaul speed mm/s

|

80

|

100

|

160

|

85

|

80

|

80

|

|

Motor kw

|

5.5

|

7.5

|

11

|

15

|

18.5*2

|

37*2

|

|

Oil pump displacement ml/r

|

25

|

40

|

63

|

63

|

63*2

|

160*2

|

|

Jacking force t

|

20

|

20

|

50

|

63

|

100

|

125

|

|

Ejection stroke mm

|

200

|

200

|

250

|

250

|

300

|

350

|

Hot Searches