- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

As your requirement

-

Dimension(L*W*H):

-

2080x1000x2130mm

-

Year:

-

2019

-

Weight (KG):

-

800 kg

-

Power (kW):

-

5.5

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control mode:

-

Automatic

-

Service Life:

-

≥15 Years

-

Machine Type:

-

Waste tire recycling

-

Usage:

-

Cut Waste Tires

-

Capacity:

-

20-60tires/h

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SFC

-

Model Number:

-

QDJ-1200

-

Voltage:

-

As your requirement

-

Dimension(L*W*H):

-

2080x1000x2130mm

-

Year:

-

2019

-

Weight (KG):

-

800 kg

-

Power (kW):

-

5.5

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control mode:

-

Automatic

-

Service Life:

-

≥15 Years

-

Machine Type:

-

Waste tire recycling

-

Usage:

-

Cut Waste Tires

-

Capacity:

-

20-60tires/h

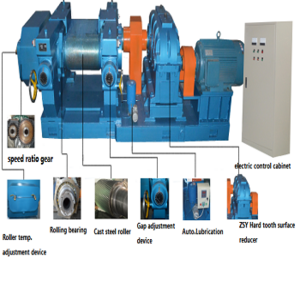

Used Tire Recycling Tyre Cutter Machine

It possesses such advantages as unique structure, advanced technology, low energy consumption, high efficiency, and long life.

Work principle: Put the tyre on the fork, it will be elevated to the wanted position by hydraulic system, and then it will be cut by the movable knife from the upper side and the stationary knife from the lower side;

Waste Tires-→Single Hook Debeader-→Tire Cutter-→Whole Tire Shredder -→ Rubber Crusher -→Screen, Conveyor Belt, Magnetic Plants-→Fiber Separator -→Fine Rubber Powder Pulverizer-→Rubber Powder

Through the tyre shredding machines , the tyre is firstly processed into small blocks, and then the crushing unit crushes and grinds the rubber block to obtain the rubber granules mixed with the rubber powder, and then through the magnetic separation and screening, conveying unit, the steel wire and the rubber are Completely separated. The pure rubber powder of 1-30 mesh fineness is prepared.

Use:Pulling out the wire loops from the mouth of waste tires.

2. Tire Cutter QDJ-1200

Use:Cut the whole waste tires into small parts

3. Whole tire shredder ZPS-900

Use:This machine can directly crush tires smaller than 900mm tires. At the general temperature, can be put directly crushed into 50 * 50 mm block, so the next rotating can grind into 10-30 meshes or wire and fiber separation equipment.

4. Double Rolls Rubber Crusher XKP-560: Mainly used for crack large rubber blocks into 0-30 mesh small rubber granule

1,

Our engineers can design target machines for customers and send them the drawing to confirm. We are always on the side of saving your cost.

2,In the process of production, we will take photos and send to customers for their track the progress.

3,Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

4,We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

5,We supply overseas engineer service and help to train your workers to operate the machine.

1. Delivery time of the rubber machines?

This is specially designed machine according to your specific requirement.

From engineer designing to production completion, it needs about 25 to 35 days.

2. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production.

Every machine will be fully assembled and carefully tested before shipment.

3. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

4. Are you able to give installation and commissioning overseas? How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation.

Small machine usually takes within 2~3 days.

Big plant usually takes about 30 days.

5. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order.

The core of our company culture is innovation, quality, integrity and efficiency. Also we have had much good cooperation with world famous rubber production manufacturers. If you come to our factory, we can show you're the user around us.

6. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao Liuting airport.

We will pick up you at the airport.

Welcome your inquiry and visiting our factory!