Control Panel

more convenient and easy to operation

|

Mode

|

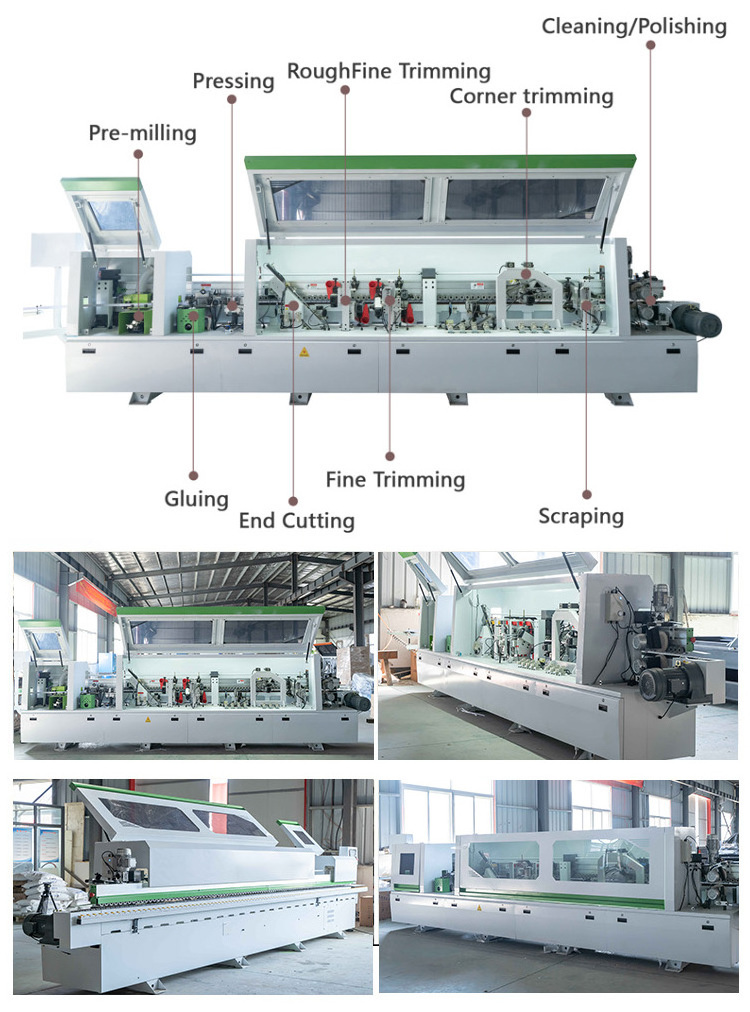

GD-2400 Edge Banding Machine

|

|

Edge banding thickness

|

0.4-3mm

|

|

Banding tape width

|

10-50mm

|

|

Mini width of wood

|

>80mm

|

|

Feeding motor power

|

0.75kw

|

|

Heating power

|

0.75kw

|

|

Glue spreading motor power

|

0.37kw

|

|

Fine trimming motor power

|

0.75kw*2

|

|

Polish motor power

|

0.18kw*2

|

|

Feeding speed

|

13m/min

|

|

Air pressure

|

0.7Mpa

|

|

Machine size

|

4500*900*1500mm

|

|

GW

|

2200KG

|