- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2500x1800x1200 mm

-

Weight:

-

1800 KG

-

Product name:

-

hair tube

-

Function:

-

protect the surface

-

Material:

-

ALUMINUM

-

Other name:

-

printing machine

-

Color:

-

white customized

-

Size:

-

12-38mm

-

Keywords:

-

aluminum collsapible tube

Quick Details

-

Voltage:

-

380 v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YR

-

Dimension(L*W*H):

-

2500x1800x1200 mm

-

Weight:

-

1800 KG

-

Product name:

-

hair tube

-

Function:

-

protect the surface

-

Material:

-

ALUMINUM

-

Other name:

-

printing machine

-

Color:

-

white customized

-

Size:

-

12-38mm

-

Keywords:

-

aluminum collsapible tube

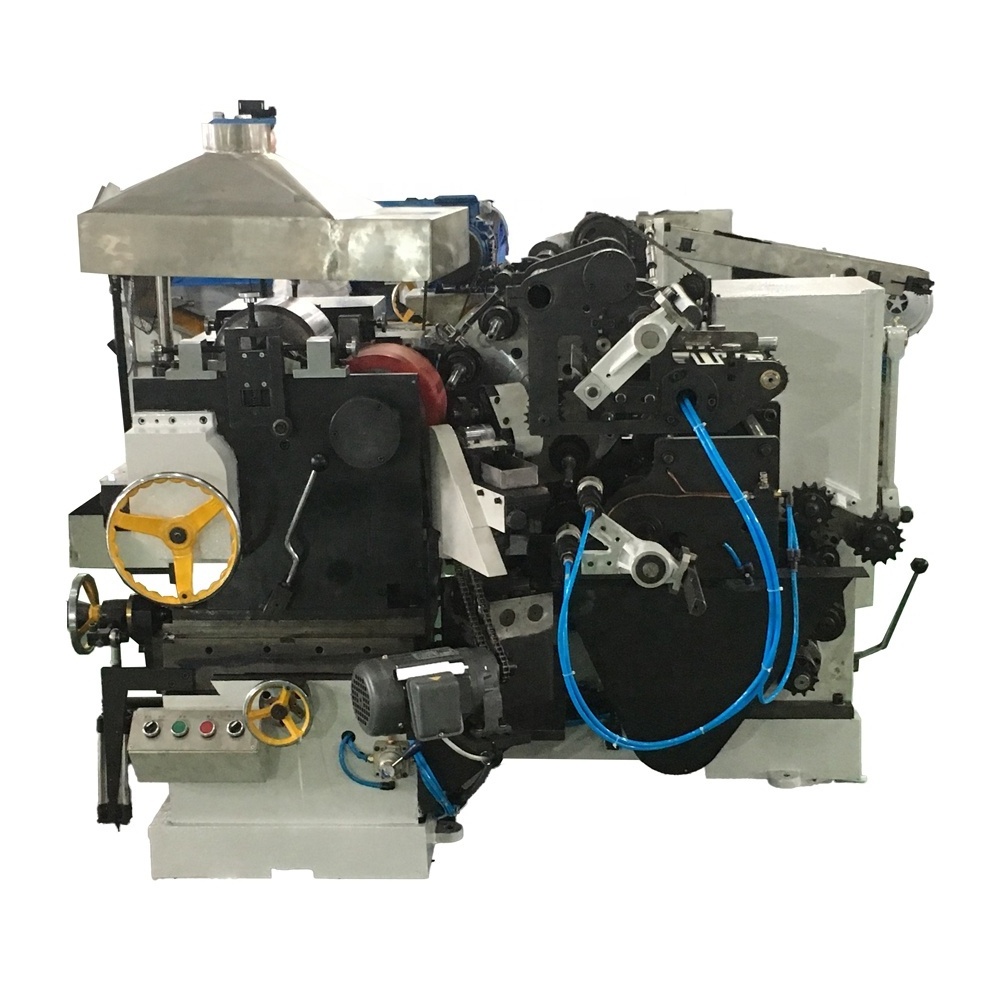

DYD 01 base-coating machine is supporting equipment for aluminum collapsible tube line. It is suitable for coating the outer surface of aluminum tubes.

A polyester or epoxy base is applied over the tubes to receive prints. Germ tubes drop into “V” slot are inserted over mandrel by push rod mechanism. The mandrel turns to the coating station, coating is applied with rotating rubber rollers over the spinning tubes. Fine coating film adjustment is possible with manual adjustment of take up and intermediate rollers.

Coated tubes are unloaded by manipulator. The manipulator takes tubes from the mandrel and puts them on the transferring chain towards the base-coating oven.

|

TECHNICAL DATE

|

|

|

|

|

||||

|

TUBE RANGE

|

|

|

φ11-φ38 MM

|

|

||||

|

TUBE LENGTH

|

|

|

≤210 MM

|

|

||||

|

PRODUCTION SPEED

|

|

|

≤60 tubes/min

|

|

||||

|

MOTOR POWER

|

|

|

0.75 KW

|

|

||||

|

DIMENSIONS

|

|

|

2500*1800*1200 MM

|

|

||||

|

WEIGHT

|

|

|

1800 KG

|

|

||||

- Main features

- 1. The machine can work synchronously with printing machines or work alone.

2. SIEMENS PLC controls speed and frequency. Mandrel rotation adopts frequency control.

3. Main units of the machine like mandrel plate and cam are processed by CNC equipment, which increase the accuracy of mandrel rotation.

4. The manipulator takes tubes up and down automatically. The machine has self-inspection system. If tubes are not well inserted into the mandrels, the machine would stop working automatically. No tubes, no printing. The mandrel can be prevented from being accidentally coated.

Q1:WHAT’S YOUR COMPANY’S MAIN P RODUCTS?

A: WE ARE PROFESSINAL PRODUCE THE ALUMINUM CAN MAKING LINE,ALUMINUM TUB EMAKING LINE,TOOTHPASTE LINE,LAMINATED TUBE MAKING LINE AND PLASTIC TUBE MAKING LINE.

Q2:ARE YOU MANUFACTURE OR TRADING COMPANY?

A: BOTH WE ARE.WE HAVE OUR OWM MACHINERY MANUFACTURE.WE ALSO SOLD THE RELATION GOODS OF OUR MACHINE

Q3:WHERE ARE YOU OCATED?IS IT CONVENIENT TO VISIT YOU.

A:WE ARE LOCATED IN WUXI.IT IS NEAR TO SHANGHAI.YOU CAN FLY TO WUXI OR SHANGHAI.WE CAN PICK YOU UP AT THE AIRPORT.WELCOME TO VISIT US.

Q4: HOW CAN YOU GUARANTEE QUALITY?

A:1.WE HAVE COMPLETED WORKING SYSTEM AND PROCEDURES AND WE FOLLOE THEM VERY STRICYLY.

2.WE WILL DO STRICT TEST RUNNING BEFORE THE SHIPPMENT.

3.THE ELECTRICAL PART WITH ALL WORLD FAMOUS BRAND.

4.ALL OF OUR MACHINE WITH CERTIFICATE.

Q5:CAN YOU OFFER OVERSEAS TECHNICAL SUPPORT.

A:YES.WE CAN SEND OUR ENGINEER TO YOUR COMPANY TO SET THE MACHINE AND TRAIN YOUR STAFF.