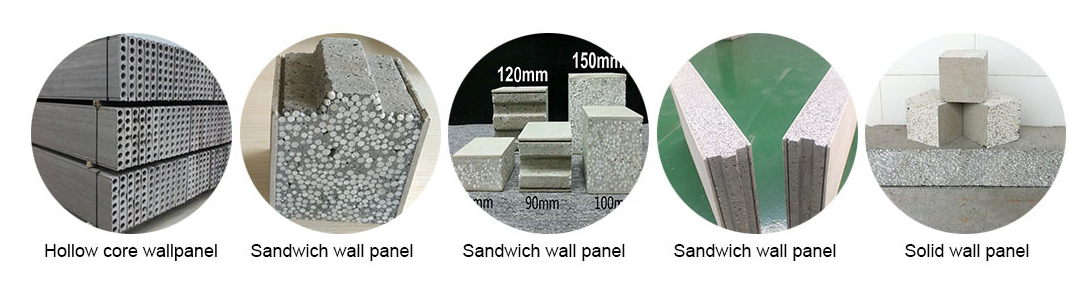

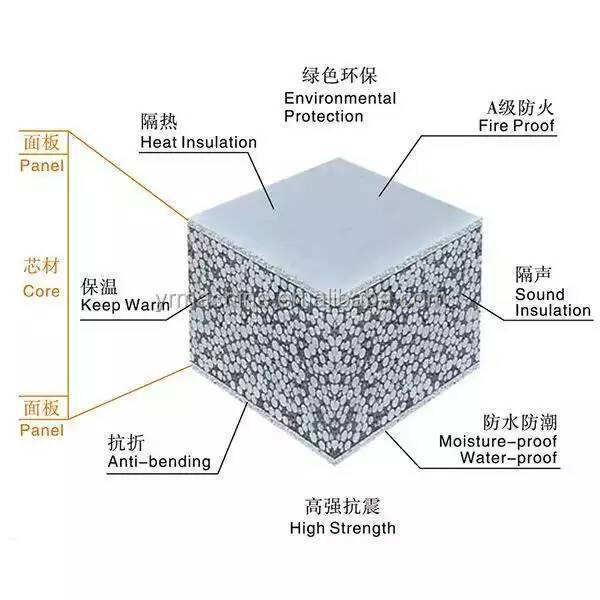

1.The lighter material of the brick used weighs 25% to 40% of the weight of the bricks.

2.High thermal insulation.

3.Remove a higher sound.

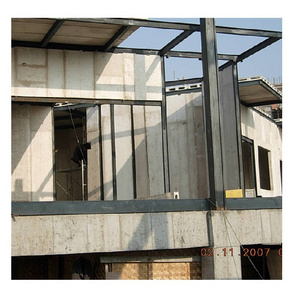

4.Install faster 4 times than the regular blocks.

5.Wall does not need the expenses of the work of the plaster.

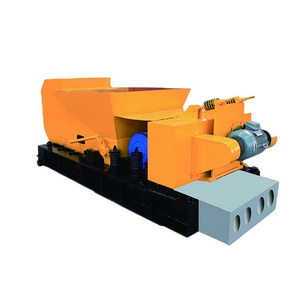

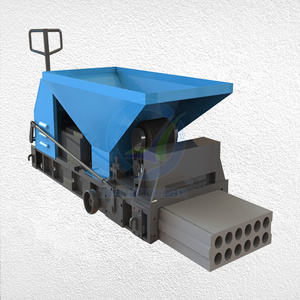

6.Change the cement used to modern materials doubles the daily production and make the product lighter weight.

7. Manufacturing mold molds so that the measurement can be changed according to demand.