- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Guangdong, China

-

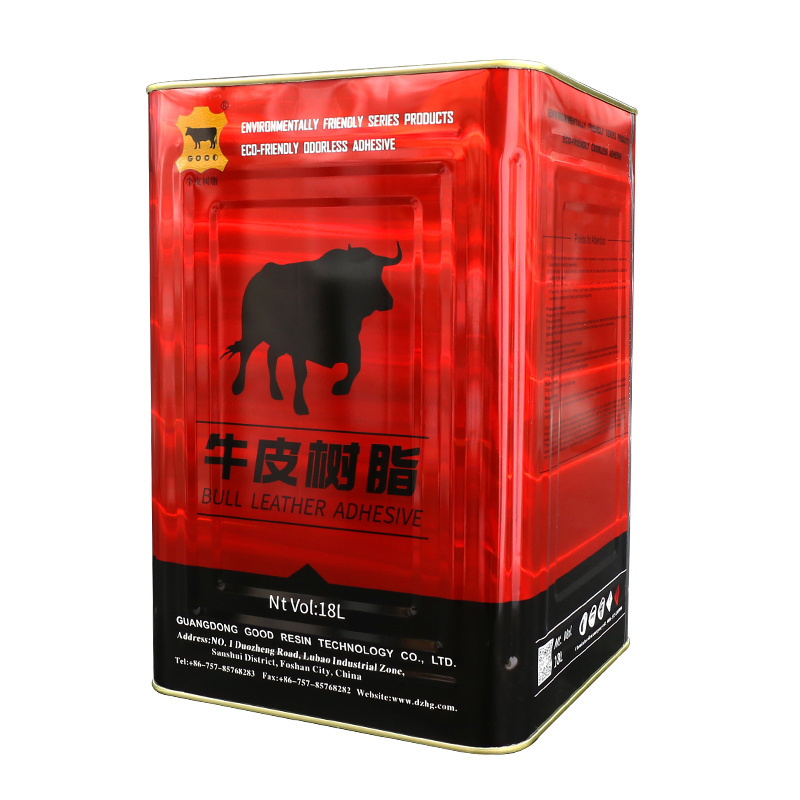

Brand Name:

-

GOOD

-

Model Number:

-

HN-90

-

Type:

-

Liquid glue

-

Appearance:

-

colorless transparent viscous liquid

-

Product name:

-

shoe sole glue

-

Keywords:

-

PU glue

-

Shelf life:

-

6-12 Months

-

Certificate:

-

ROHS

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

Polyurethane adhesive

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GOOD

-

Model Number:

-

HN-90

-

Type:

-

Liquid glue

-

Appearance:

-

colorless transparent viscous liquid

-

Product name:

-

shoe sole glue

-

Keywords:

-

PU glue

-

Shelf life:

-

6-12 Months

-

Certificate:

-

ROHS

shoe sole glue for PVC PU EVA TPR rubber sole

| Product Name | Shoe Sole glue |

| Item No. | HN-90 |

| Appearance | colorless transparent viscous liquid |

| Components | Resin, Butanone(MEK), Acetone, Toluene, Ethyl acetate. |

| Solid Content | 13%~15% |

| Viscosity | 1600~1800CPS/30°c |

| Heat Resistance | 90°c |

| Open Time | 8~12 minutes |

| Product Feature |

Strong yellowing resistant, heat resistant, good initial bonding strength, suitable for handwork and production line. |

| Application |

Suitable for bonding of many materials such as PVC, PU, TPR, rubber, leather in footwear industry. |

| Shelf Life | 12 months |

| Warning |

1. Do not mix the product with other adhesives 2.The product should be tightly sealed and kept in cool and dry places between 5~40℃. Keep

away from fire.

3. Operators should wear protective equipment. |

| Note for Application |

1.There is stability problem in storage and the process of using PU adhesive. To ensure the quality of PU adhesive, please use them according to the production date, and follow first-in-first-ou t method to manage inventory. 2. Please add some hardener by 3~5% to the adhesive and mix it up before application of the adhesive, and use it up within 4 hours. Do not pour it back into the adhesive if cannot use it up in 4 hours. 3. If the adhesive is for export, the temperature will be rather high inside the container during the transportation. To ensure the quality, please add 3~5% hardener and mix it up when you use it. Otherwise, please use item 868HK, 90 or 858H. 4. Please test the heat- resistant, tensile strength, etc to make sure whether our products can meet the requirements of your customers. |