- Product Details

- {{item.text}}

Quick Details

-

Min.Thickness of Die Block (mm):

-

300 mm

-

Ejection Force(kN):

-

200 kN

-

Ejection Stroke(mm):

-

100 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOQIAO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

600x600x800 working size

-

Weight (KG):

-

10000

-

Power (kW):

-

15

-

Applicable Industries:

-

Foundry

-

Product name:

-

Die casting machine aluminium cookware casting molding machine

-

Application:

-

Aluminum casting

-

Usage:

-

Motorcycle parts and others cast

-

Feature:

-

Human-computer interface and real-time display

-

Color:

-

OEM

-

Free sample:

-

No

-

Weight:

-

3.6ton

-

Certification:

-

CE/ISO9001

Quick Details

-

Machine Type:

-

Gravity die casting machine

-

Core Components:

-

Operation system

-

Max.Thickness of Die Block (mm):

-

500 mm

-

Min.Thickness of Die Block (mm):

-

300 mm

-

Ejection Force(kN):

-

200 kN

-

Ejection Stroke(mm):

-

100 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOQIAO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

600x600x800 working size

-

Weight (KG):

-

10000

-

Power (kW):

-

15

-

Applicable Industries:

-

Foundry

-

Product name:

-

Die casting machine aluminium cookware casting molding machine

-

Application:

-

Aluminum casting

-

Usage:

-

Motorcycle parts and others cast

-

Feature:

-

Human-computer interface and real-time display

-

Color:

-

OEM

-

Free sample:

-

No

-

Weight:

-

3.6ton

-

Certification:

-

CE/ISO9001

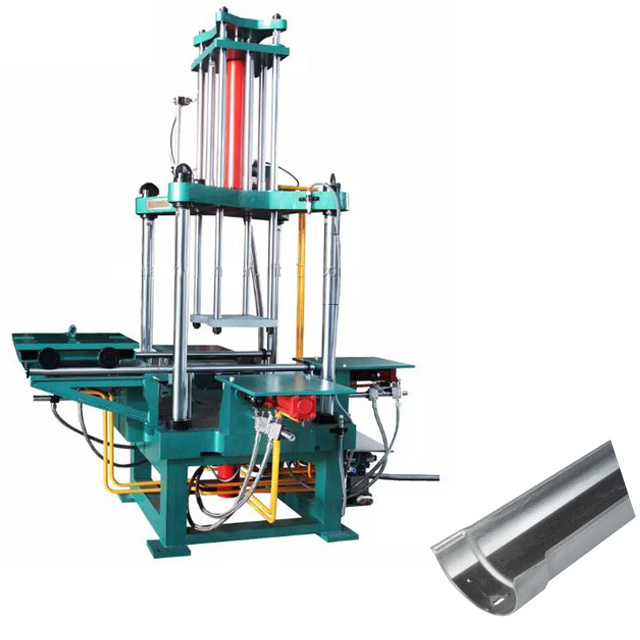

Gravity Green Sand Molding Part Making Machine Pressure Die Casting Machine

|

Model |

Maximum opening of side mould |

Mininum closing of side mould |

Highest opening of upper mould |

Lowest closing of upper mould |

Power |

Weight |

|

BQ34-6-1 |

800mm |

400mm |

1000mm |

500mm |

11KW |

2.5 T |

|

BQ34-6-2 |

1000mm |

500mm |

1100mm |

500mm |

15KW |

3.8 T |

|

BQ34-6-3 |

1200mm |

600mm |

1300mm |

550mm |

22KW |

6.3 T |

BQ34-6 horizontal gravity casting machine

This horizontal gravity casting machine has opening moulds of front, rear, left, right, up and down six directions and ejection mechanism, which can meet the need of gravity mould casting of six or less than six directions.

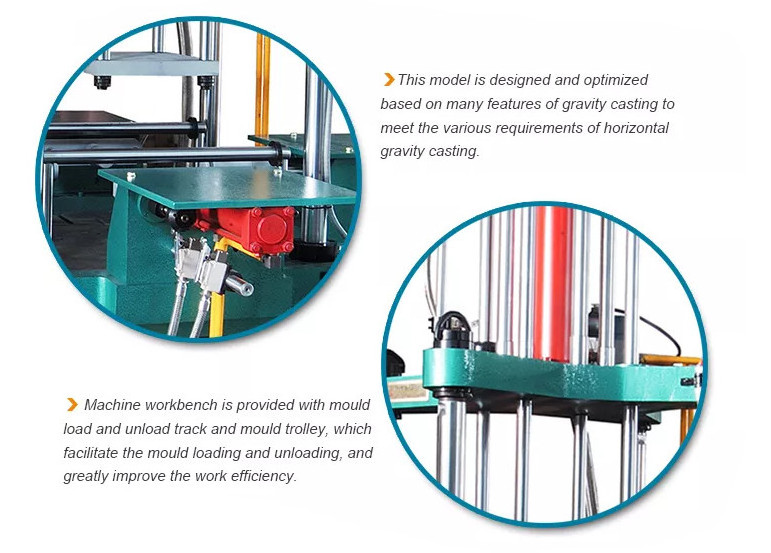

1. This model is designed and optimized based on many features of gravity casting to meet the various requirements of horizontal gravity casting.

2. The machine uses PLC and human-machine interface together with order setting program, it can set different workflows according to different needs of customers.

3. All hydraulic drive, smooth and reliable operation.

4. Machine workbench is provided with mould load and unload track and mould trolley, which facilitate the mould loading and unloading, and greatly improve the work efficiency.

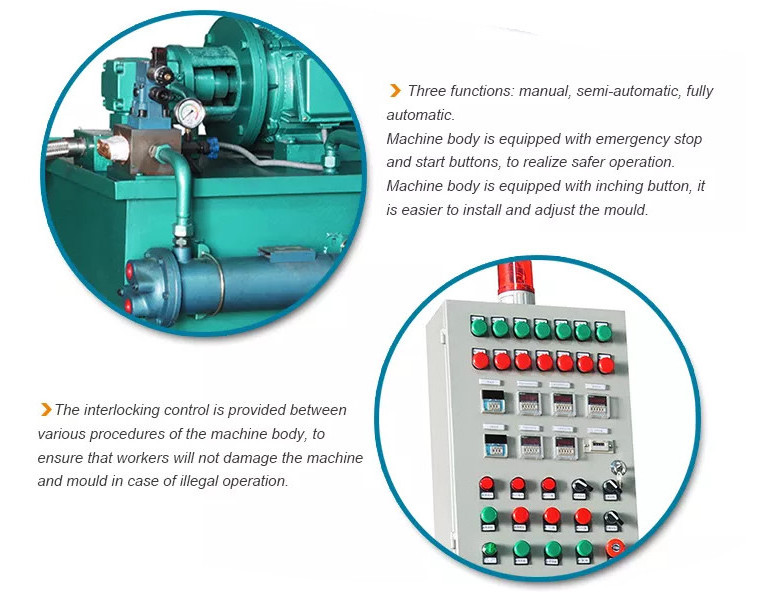

5. Three functions: manual, semi-automatic, fully automatic.

6. Machine body is equipped with emergency stop and start buttons, to realize safer operation.

7. Machine body is equipped with inching button, it is easier to install and adjust the mould.

8. Piecework function that is convenient for the production management.

9. Upper and lower moulds have functions of automatic heating and cooling.

10. The interlocking control is provided between various procedures of the machine body, to ensure that workers will not damage the machine and mould in case of illegal operation.

11. The machine can produce various high quality aluminum products such as automotive wheel drum, cylinder block, cylinder head of motorcycle, shock absorber, hydraulic pump, brake pump, valve, etc.