- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

110KW

-

Dimension(L*W*H):

-

1400*1600

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

plating style:

-

magnetron sputtering

-

avalible color:

-

diamond blue changing color

-

Application:

-

cosmetic accessories, sanitary accessories

-

Control system:

-

PLC

Quick Details

-

Machine Type:

-

manufacture plant, Painting Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Chuanggao

-

Voltage:

-

380V

-

Power:

-

110KW

-

Dimension(L*W*H):

-

1400*1600

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

plating style:

-

magnetron sputtering

-

avalible color:

-

diamond blue changing color

-

Application:

-

cosmetic accessories, sanitary accessories

-

Control system:

-

PLC

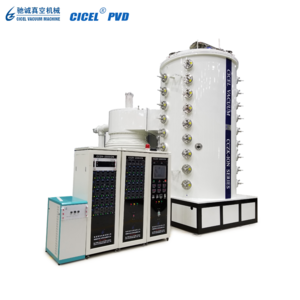

magnetron sputtering vacuum coating machine

1. Feature

Magnetron sputtering coating machine normally been combined with thermal evaporation or plasma coating machine. The product is applicable to coating metal films, alloy films, chemical films, super hardness wear-resistant films, anti-corrosion films decoration films and other different kinds of films. Combined with plasma coating technology, it can coat multilayer films, applying hardware tool, glass crafts, ceramic crafts etc.

There are many choices for the sputtering target: rotating magnetic target, mid-frequency dual-target magnetron sputtering, unbalanced magnetron sputtering target.

2. Appl ication: watches, metal outer covering, sanitary ware, mold, electronic products, crystal glass, eyeglass frame, tableware, knives, etc.

Available color: gold, silver, black, red, blue, green, etc.

3. Main Technology Parameters

|

Model |

JT-1400 |

|

Vacuum chamber size |

1400*1600H |

|

Total power |

110KW |

|

Sputtering power |

110KW |

|

Chamber structure |

Vertical & single gate |

|

Chamber material |

304 Stainless steel |

|

Ultimate vacuum |

8× 10 - 4 Pa |

|

Pump-down time |

8×10 - 2 Pa≤6 |

|

Vacuum system |

1* Diffusion pump + 1* holding pump |

|

Water-cooling system |

|

|

Control method |

Manual/automatic all-in-one electric control cabinet |

|

Remark |

Configuration of coating equipment can be designed according to the requirement of the coated products |