- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

After-sales Service Provided:

-

Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Engineers available to service machinery overseas

-

Name:

-

Roll Forming Machine

-

Speed:

-

8pcs/min

-

Forming methord:

-

Extrusion

-

Tile shape:

-

Customized

-

Tile size:

-

420x330mm

-

Tile raw material:

-

Cement+ Sand

-

Usage:

-

Roof

-

Workers:

-

8 persons/Shift

-

Keywords:

-

Roll Forming Machine

-

Certification:

-

ISO9001:2015

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

CONCRETE

-

Production Capacity:

-

8pcs/minute

-

Place of Origin:

-

Zhejiang, China

-

After-sales Service Provided:

-

Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Engineers available to service machinery overseas

-

Name:

-

Roll Forming Machine

-

Speed:

-

8pcs/min

-

Forming methord:

-

Extrusion

-

Tile shape:

-

Customized

-

Tile size:

-

420x330mm

-

Tile raw material:

-

Cement+ Sand

-

Usage:

-

Roof

-

Workers:

-

8 persons/Shift

-

Keywords:

-

Roll Forming Machine

-

Certification:

-

ISO9001:2015

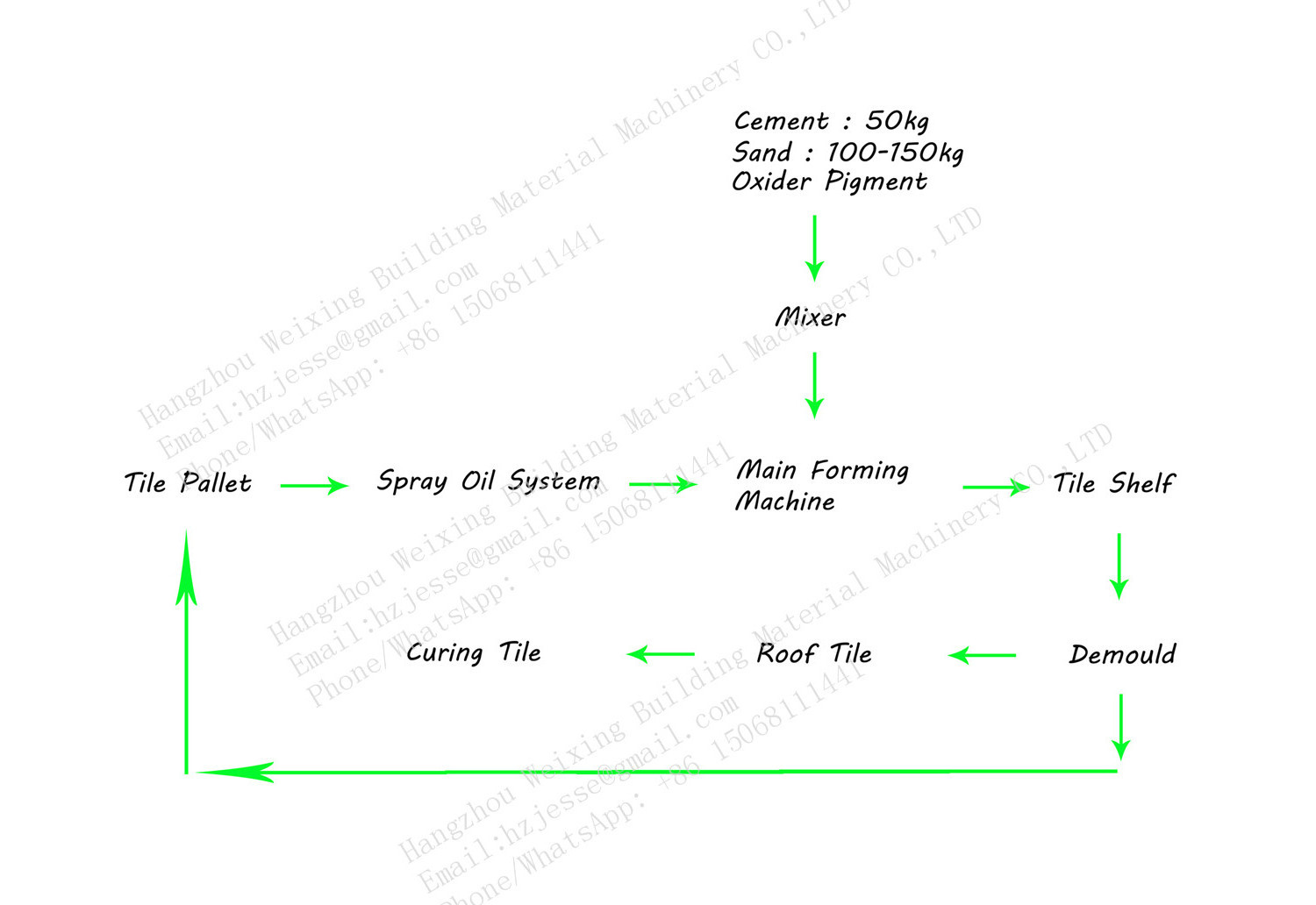

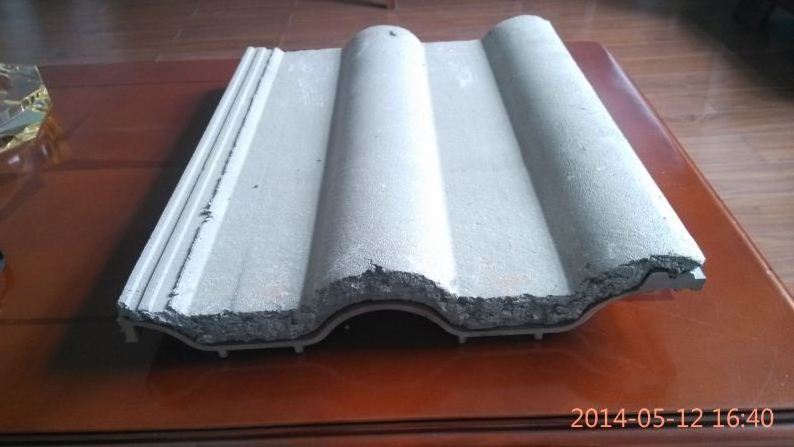

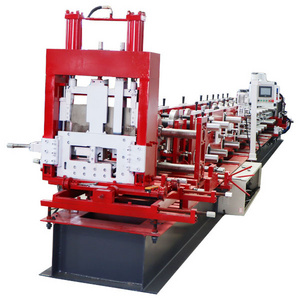

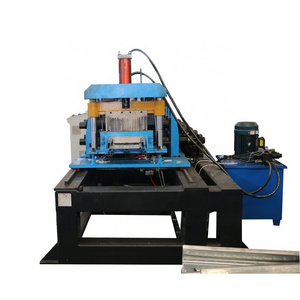

Roll Forming Machine SM-8 is a automatic cement roof tiles forming machine The machine produces cement roof tiles. It make different shape tiles according to different molds.The tiles is strong anti-seepage water,strong anti-knock. Cement and yellow sand are the raw material of the tile.Tile machine produces tiles fast with high yields.It can produce 5 pieces of tiles each minute.It is the preferred green building.

Technical Parameter

| Technical Parameter: | |

| Item NO.: | SM-8 |

| Product's name: | Concrete roof tile machine |

| Forming speed: | 8 pcs/minute |

| Annual production: | 1,000,000 pcs (8 hours/day) |

| Product Dimension: | 420*330mm |

| Method: | Extrusion |

| Voltage: | 380V |

| Power: | 11KW |

| Materials: | Rolled steel |

| Employee: | 8 persons/group |

| Surface color: | Optional |

| Packaging: | Bulk & Wooden case |

| Minimum order: | One set |

| Delivery time: | 20-30 days after have deposit |

| Cross weight: | About 22,000KG |

| Cube type: | 20 GP/Set |

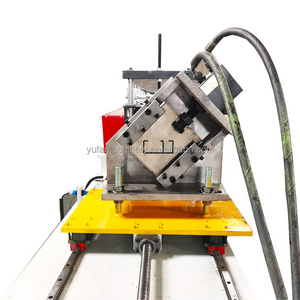

Basic Scheme

| NO. | Name | Quantity | Unit |

|

1 |

SM-8 Main machine(include 7pcs alumimu, tile pry) | 1 | Set |

| 2 | Forming system(Forming block,press roller and so on) | 1 | Set |

| 3 | Hydraulic station | 1 | Set |

| 4 | Raw material Mixer | 1 | Set |

| 5 | Raw material conveyor | 1 | Line |

|

6

|

Electric control operate cabinet | 1 | Set |

| 7 | Match color machine | 1 |

Piece |

| 8 | Coloring machine | 1 |

Set |

| 9 | Acrylic coating machine | 1 | Set |

| 10 | Semi-finished material conveyor(5m) | 1 | Line |

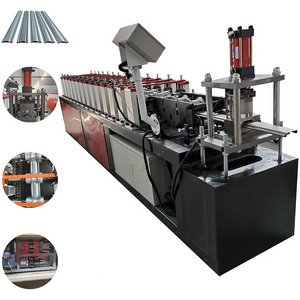

| 11 | Auto spray oil system and conveyor(1.5m) | 1 | Line |

| 12 | Blower and conveyor(1.5m) | 1 | Set |

| 13 | Coloring conveyor(2m) | 1 | Line |

| 14 | Acrylic coating conveyor(2m) | 1 | Line |

| 15 | Tile conveyor(5m) | 1 | Line |

| 16 | Acrylic tank | 1 | Piece |

| 17 | Release oil tank | 1 | Piece |

| 18 | Aluminum tile pry | 7 | Piece |

| 19 | Steel tile pallets/molds | 2000 | Piece |

Auxiliary Machine(customer owned by yourself )

| 1 | Workshop: 10x20 square meter | 1 space |

| 2 | Tile shelf: 120 pieces/shelf | 17 shelf |

| 3 | Air compressor: W-0.9/7 | 1 Set |

| 4 | Hand pallet truck: 3T | 1 -3 set |

| 5 | Maintenance room: 90 square meter | 1 space |

| 6 | Tile yard: 600 square meter | 1 space |

Technological Process