- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

10000 KG

-

Suitable forpaper, laminated film:

-

Plastic film, aluminum foil, woven, Non woven

-

Coating Method:

-

Veins roller metering coating

-

Coating Width:

-

800-1600mm

-

Mechanical Speed:

-

150m/min

-

Coating Speed:

-

10-120m/min(depend on material)

-

Oven Length:

-

10-20m

-

Oven temperature:

-

50-200℃

-

Heating type:

-

Electricity heating, Oil heating, Steam heating, Stove heating

-

Unwinding and rewinding Dia.:

-

800mm, 1000mm, 1200mm

-

Non-stop roll change:

-

Yes

Quick Details

-

Voltage:

-

338V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Maowei brand

-

Weight:

-

10000 KG

-

Suitable forpaper, laminated film:

-

Plastic film, aluminum foil, woven, Non woven

-

Coating Method:

-

Veins roller metering coating

-

Coating Width:

-

800-1600mm

-

Mechanical Speed:

-

150m/min

-

Coating Speed:

-

10-120m/min(depend on material)

-

Oven Length:

-

10-20m

-

Oven temperature:

-

50-200℃

-

Heating type:

-

Electricity heating, Oil heating, Steam heating, Stove heating

-

Unwinding and rewinding Dia.:

-

800mm, 1000mm, 1200mm

-

Non-stop roll change:

-

Yes

Why Choose Us

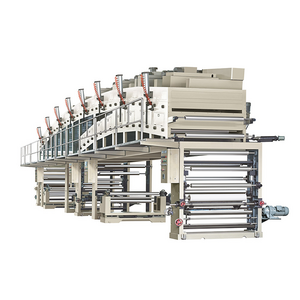

Specification

|

Model

|

TB Series Coating Laminating Machine

|

|

Coating Method

|

Veins roller metering Coating

|

|

Coating Width

|

800~1600mm(Customized)

|

|

Working Speed

|

10~120m/min(depend on adhesive and material)

|

|

Unwinding Diameter

|

800mm/1000mm/1200mm(Customized)

|

|

Rewinding Diameter

|

800mm/1000mm/1200mm(Customized)

|

|

Heating Source

|

Electric, Oil, Steam, Stove

|

Machine Performance Characteristics

1.This machine adopts frame structure type and length of machine can be determined by the user.

2.AC frequency stepless speed regulation pre-traction coating laminating traction rewinding etc. are

synchronously

controlled.

3. PLC control with man-machine interface can achieve many advantages such as preciseness, sensitivity easy-operation anti-jamming.

4.This machine adopts veins roller measuring coating type and auto glue homognized function; the veins roller can be processed by laser carving,electronic carving machine extruding etc.

5.Movable double shafts,pneumatic back pressure scraper and three-dimension adjustment can

efficiently control the directions and pressure of scraper.

6.This machine adopts separately constant temperature drying system and various kinds of heating types such as hot air cycling heating, IR heating etc; automatically controlling temperature in each temperature zone adjustable cycling in-out air system.

7. The guide roller in the oven adopts the master-slave double sliding installation mode to drive synchronously with the main machine; The oven can be opened on both sides or the top of the cylinder, and the operation and maintenance platform and guardrail on both sides can be used.

8. Automatic counting, automatic lifting speed, automatic belt break detection, automatic fault reporting, automatic clutch of pneumatic components, etc.

9. The winding adopts double-station turnover type or single-station hydraulic lifting type, and the material roll adopts air

expansion shaft loading and unloading.

expansion shaft loading and unloading.

Unwinding Unit

(Customized)

-single station

-single station

-double station (

Roll change without line stopping

)

*

Single and double stations are available as options*

Rewinding Unit

(Customized)

-single station

-single station

-double station ( Roll change without line stopping)

*Single and double stations are available as options*

*Single and double stations are available as options*

Factory overview

Zhejiang Maowei Machinery Technology Co., Ltd, former name as Wenzhou Weisheng Machinery Co.,Ltd, is specialized in machinery designing, manufacturing, selling and service providing.

We have independently developed various kinds of series of coating machine, laminating machine and export to various country successfully.

Recommend Products

Hot Searches