- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

GERMANY PA

-

Cutting Area:

-

1200*1800MM

-

Cutting Thickness:

-

1-22 die board, 1-22mm die board

-

Control Software:

-

AutoCAD

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YT

-

Weight (KG):

-

2000 KG

-

Name:

-

Low Price Industrial Wood Acrylic Sheet Laser Cutting Machines

-

Type:

-

die board laser cutting machine

-

Color:

-

Red or blue for low price wood moulding machines

-

cut:

-

Plywood, Wood

-

Laser tube:

-

Co2 Glass

-

Certification:

-

According to goverment need

Quick Details

-

Laser Type:

-

CO2

-

Cutting Speed:

-

25-30meters/hour

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

GERMANY PA

-

Cutting Area:

-

1200*1800MM

-

Cutting Thickness:

-

1-22 die board, 1-22mm die board

-

Control Software:

-

AutoCAD

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YT

-

Weight (KG):

-

2000 KG

-

Name:

-

Low Price Industrial Wood Acrylic Sheet Laser Cutting Machines

-

Type:

-

die board laser cutting machine

-

Color:

-

Red or blue for low price wood moulding machines

-

cut:

-

Plywood, Wood

-

Laser tube:

-

Co2 Glass

-

Certification:

-

According to goverment need

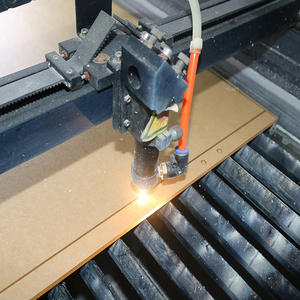

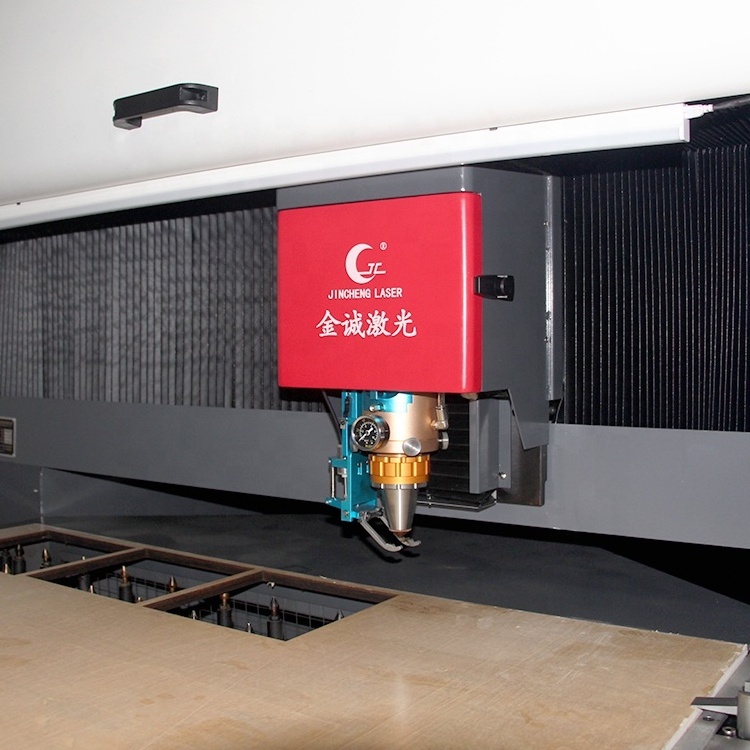

Low Price Industrial Wood Design Moulding Laser Cutting Machines

Split type 400w single laser cutting die board cutting machine adopts the split type design, laser head stationary, mesa movement, reduce the laser reflector and making higher cutting precision . The cutting effect is better. A new design of exhaust system, smoke exhaust rate well, create a better working environment for you. The machine can cut 18mm and 22mm laser die board. (1-3mm iron, stainless steel plate can also be cut if added oxygen ). Maintenance is simple, machine casting is made of high quality cold-rolled steel plate.

Functions and usage:1.Cross table construction, stable working, small floor space required for machine.

2.Adopt domestic most advanced 400w CO2 sealing type water-cooled laser tube, combined with good precision of CNC control mechanical systems. It can reach cutting die manufacturing precision and at the same time greatly reduce the production cost . Suitable for wooden cutting die and precision electronic cutting die production.

3.Unique smoke exhaust design, create a good working environment for you. Using the most advanced laser tube in China and no need to add any auxiliary gas when cutting, laser cutting die consumption is extremely low. Only 220v external power source is need and making low cost., There is no need to wait long time for start and running the machine.

Simple and clear cutting line adjustment technology. Cutting software can be compatible with AutoCAD. Coredraw, Adobe Photoshop. Editing path is very easy and convenient.

|

Model No.

|

|

JC-1218-400W

|

|

||

|

Power

|

|

400 W

|

|

||

|

The table style

|

|

Cross table construction

|

|

||

|

Laser output power

|

|

laser glass pipe

|

|

||

|

X-axis travel-length

|

|

1200mm

|

|

||

|

Y-axis travel-length

|

|

1800mm

|

|

||

|

Cutting speed

|

|

18 mm die board

|

|

||

|

|

|

20-28m/h

|

|

||

|

Re-Positioning Precision

|

|

≤0.02mm

|

|

||

|

Cutting width kerf

|

|

0.45mm, 0.71mm, 1.05/1.07mm at one time (die board)

|

|

||

|

Transmission system

|

|

Ball screw & Linear guide (TAIWAN)

|

|

||

|

Driving system

|

|

Japan high-precision servo motors

|

|

||

|

Optical system

|

|

US program

|

|

||

|

Moving structure

|

|

Cross table

|

|

||

|

Overall dimensions (L x W x H)

|

|

4391*3930*1800mm

|

|

||

|

G. Weight

|

|

2000kg

|

|

||

Installation and Training Terms

1.YITAIPACKING-MATERIACCESSORIES(KUNSHAN)CO.,LTD. provides technical training for the operators. Training content is including training of installation, mechanical operation, and software usage.

2.Once the buyer and seller confirm the cooperation, the buyer can arrange technician to the seller's factory for the training of installation and training .

3.Within 15 days after receipt of the buyer's written notice, the seller will send the competent engineer(s) for contract equipment's installation, commissioning, acceptance test and training of the buyer's operators (max. 2 persons) for a total period of 7(seven) working days for free.Extra 7 working days need to be paid.One working day is 150usd.Training of machine and software should be done by seller YITAIPACKING-MATERIACCESSORIES(KUNSHAN)CO.,LTD. All technicians cost such us for traveling time, accommodation, air tickets, and meal allowance is covered by the buyer.

Guarantee

1.The guarantees below are provided by YITAIPACKING-MATERIACCESSORIES(KUNSHAN)CO.,LTD (YT Packing) in conjunction with the sellers.

2.Our guarantee is 12 month.

4.During the warranty period,every time our technician is sent to fix a customer problem, it is agreed that the buyer will undertake costs relating to the tickets,food and hotel. Within 12 months, seller will send an engineer in condition time for buyer's request with free fixing fee.

5.After 12 month, seller will send an engineer in condition time for buyer's request . The buyer need to pay fixing fee and salary for the technician. It is 150USD per working day per person.

6.Spare parts not included in the guarantee(laser tube,lens,mirror,laser head),normal spare parts is better prepared by user.

Equipment size:4391*3930mm

Floor space size:5000*4400mm