- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

6000 - 24000

-

Spindle Taper:

-

BT40/BT30

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SZGH

-

Model Number:

-

SZGH-650-5

-

Dimension(L*W*H):

-

1650*1800*2450

-

Weight (KG):

-

2900

-

Spindle Motor Power(kW):

-

3.7km/5.5kw/7.5kw

-

Max. Table Load(kg):

-

1800 kg

-

Marketing Type:

-

New Product 2023

-

Brand:

-

SZGH

-

After-sales Service Provided:

-

Online Support

-

Axis:

-

5 axis

-

Machine Type:

-

Cnc Milling Machine Vertical

-

Usage:

-

Metal Parts Machining

-

Precision:

-

High Precision Machine

-

Spindle Speed Ranges:

-

6000~24000rpm

-

Product Name:

-

CNC lathe/ milling machine

-

Fuction:

-

Milling Drilling

-

Spindle motor:

-

3.7kw(option 5.5kw)

Quick Details

-

Table Travel (X) (mm):

-

500

-

Table Travel (Y) (mm):

-

600

-

Table Travel (Z) (mm):

-

300

-

Range of Spindle Speed(r.p.m):

-

6000 - 24000

-

Spindle Taper:

-

BT40/BT30

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SZGH

-

Model Number:

-

SZGH-650-5

-

Dimension(L*W*H):

-

1650*1800*2450

-

Weight (KG):

-

2900

-

Spindle Motor Power(kW):

-

3.7km/5.5kw/7.5kw

-

Max. Table Load(kg):

-

1800 kg

-

Marketing Type:

-

New Product 2023

-

Brand:

-

SZGH

-

After-sales Service Provided:

-

Online Support

-

Axis:

-

5 axis

-

Machine Type:

-

Cnc Milling Machine Vertical

-

Usage:

-

Metal Parts Machining

-

Precision:

-

High Precision Machine

-

Spindle Speed Ranges:

-

6000~24000rpm

-

Product Name:

-

CNC lathe/ milling machine

-

Fuction:

-

Milling Drilling

-

Spindle motor:

-

3.7kw(option 5.5kw)

Product Description

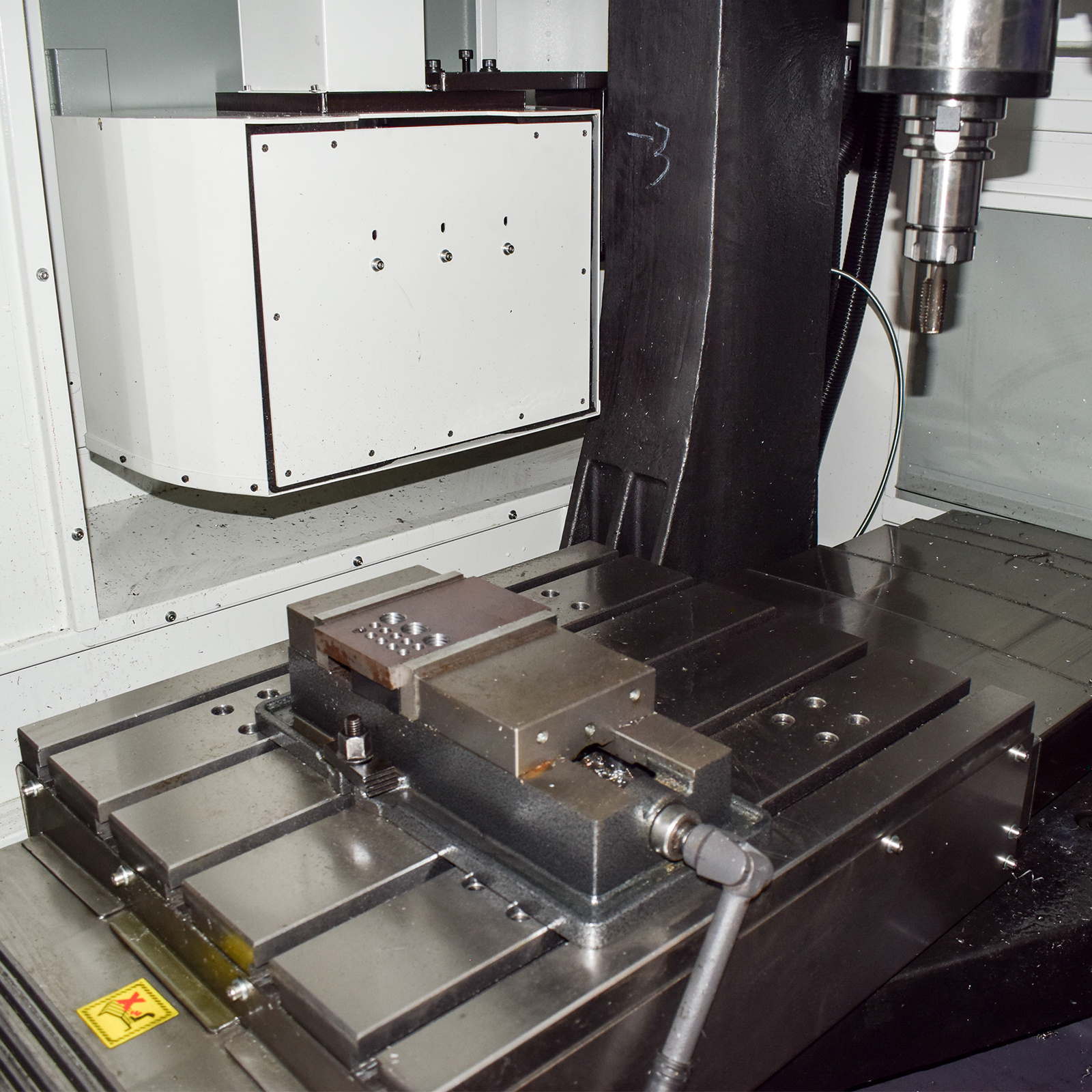

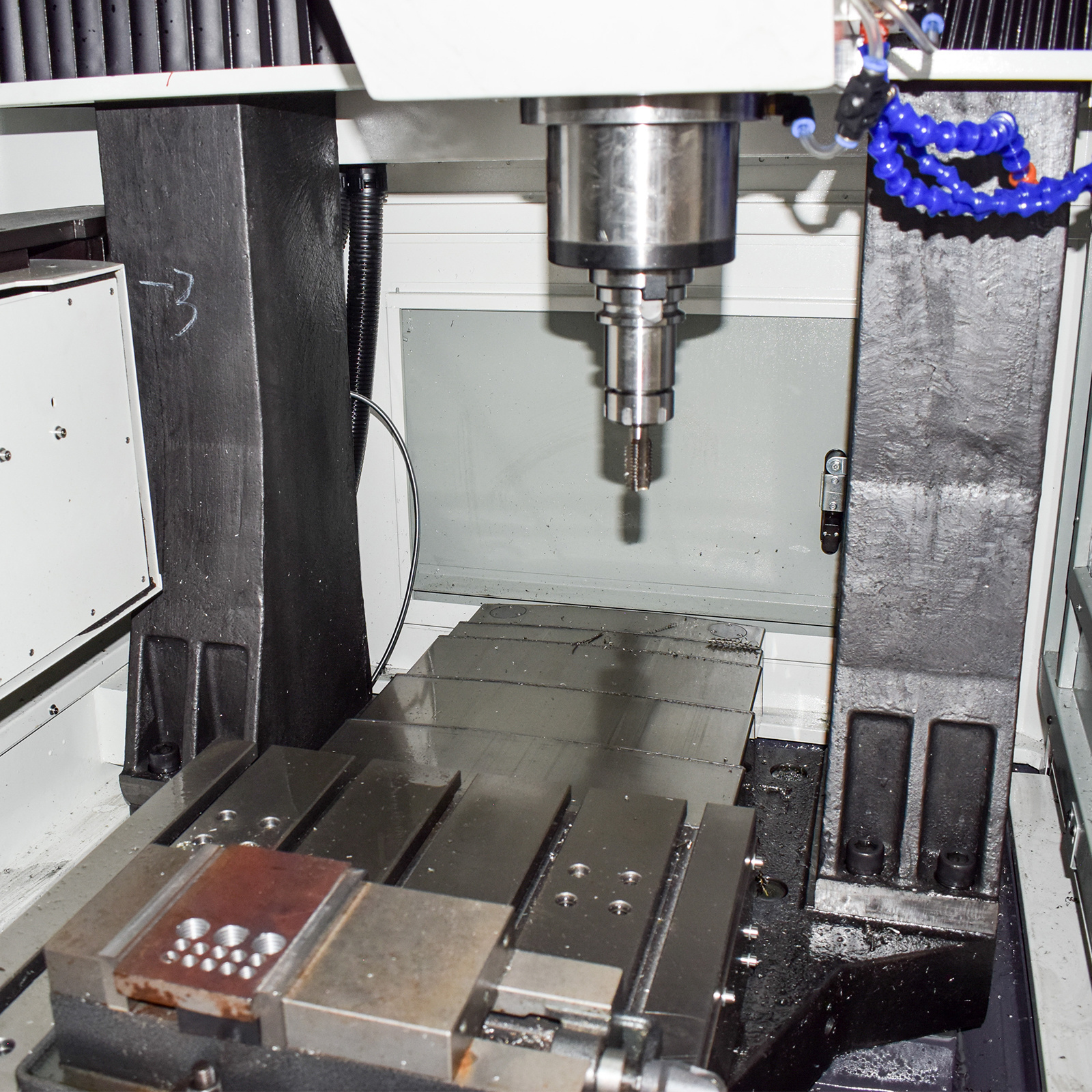

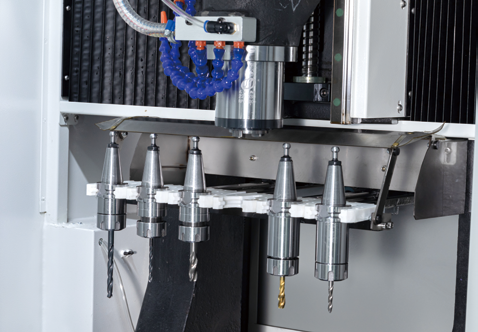

On the basis of SZGH-540 or SZGH-650, a 4-axis rotary table or a 5-axis rotary table can be added to realize the function of completing multi-faceted three-dimensional processing in one clamping.It is widely used in mold making and other functions that require drilling and tapping or three-dimensional carving on multiple surfaces.Among them, SZGH-540 can support up to 8 station tool magazines on the basis of adding external shafts, and SZGH-650 can support up to 10 station tool magazines on the basis of machining external shafts.

PATENT BASE

Anti-deformation patented heavy-duty base, heavy enough to support fast.

GOOD VIBRATION RESISTANCE

Heavy enough to support bar and large parts, anti-vibration, improve precision and smoothness.

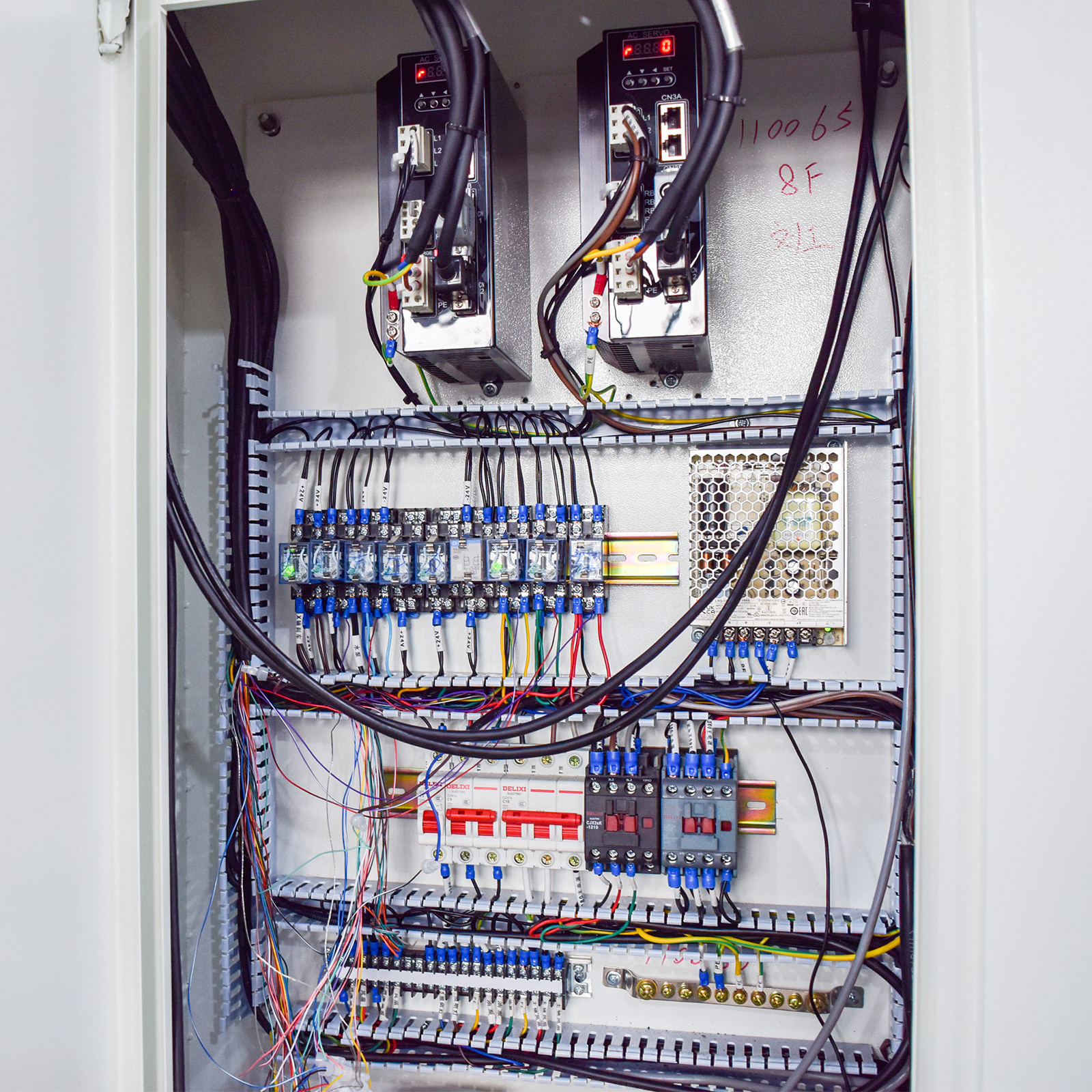

UNIFIED ELECTRONIC CONTROL SYSTEM

Adopt SZGH electric control package to make electro-mechanical cooperation play the best efficiency.

HIGH QUALITY

The key components adopt high-quality wear-resistant configurations such as Taiwan, and the sleeve and spindle are all dynamically balanced.

|

Project

|

|

SZGH-540

|

SZGH-650

|

|

|

Processing capacity

|

Max. drilling diameter

|

Aluminum φ14mm/ Steel φ10mm

|

Aluminum φ40mm/ Steel 30mm

|

|

|

|

Max. Tapping Diameter

|

Aluminum m10mm/ Steel m8mm

|

Aluminum m25mm/ Steel m20mm

|

|

|

|

Max. milling cutter diameter

|

φ60mm

|

φ100mm

|

|

|

|

Max Spindle speed

|

5000rpm/9000rpm/30000rpm

|

6000rpm/24000rpm

|

|

|

|

Handle Type

|

BT30

|

BT40/BT30

|

|

|

|

Magazine capacity

|

6 gangs/8 magazines

|

10 gangs/12 magazines

|

|

|

|

Repeatability

|

0.01mm

|

0.01mm

|

|

|

|

Surface engraving accuracy

|

±0.06mm/±0.01mm

|

±0.02mm/±0.01mm

|

|

|

Workbench

|

Distance from table surface to spindle end

|

Minimum 150mm Maximum 350mm

|

Minimum 150mm Maximum 450mm

|

|

|

|

Effective stroke of working surface

|

500mm x 400mm

|

600mm x 500mm

|

|

|

Travels

|

X-axis effective travel

|

400mm

|

500mmm

|

|

|

|

Y-axis effective travel

|

500mm

|

600mm

|

|

|

|

Z-axis effective travel

|

200mm

|

300mm

|

|

|

Feed

|

X-axis rapid traverse

|

30m/min

|

30m/min

|

|

|

|

Y-axis rapid traverse

|

30m/min

|

30m/min

|

|

|

|

Z-axis rapid traverse

|

25m/min

|

25m/min

|

|

|

|

Various cutting suggested speeds

|

10m/min

|

10m/min

|

|

|

Spindle

|

|

5000rpm/9000rpm/30000rpm

|

6000rpm/24000rpm

|

|

|

|

Spindle Motor Power

|

2.6km/3.7kw/4.5kw

|

3.7km/5.5kw/7.5kw

|

|

|

|

Spindle type

|

mechanical spindle/ electric spindle

|

mechanical spindle/ electric spindle

|

|

|

|

Spindle taper

|

BT30

|

BT40/BT30

|

|

|

Dimensions

|

Dimensions

|

1350 x 1050 x 2050mm

|

1650 x 1800 x 2450mm

|

|

|

|

Total Weight

|

1900kg

|

2900kg

|

|

|

Machine tool specifications and component items

|

|

SZGH-540

|

SZGH-650

|

|

|

Part Specifications

|

Screw

|

25mm Taiwan precision p grade

|

32mm Taiwan precision p grade

|

|

|

|

Guide rail

|

25mm Taiwan Precision C3 Grade

|

32mm Taiwan Precision C3 Grade

|

|

|

|

Spindle

|

BT30 spindle

|

BT40/BT30 spindle

|

|

|

|

Feeding servo

|

X.Y750kw、&1.2kW

|

X.Y1.2kw、&1.5kW

|

|

|

|

Spindle servo motor

|

2.6kW/3.7kw/4.5kw

|

3.7kW/5.5kw/7.5kw

|

|

|

|

Tool magazine

|

6 /8 magazines

|

10/12 magazines

|

|

|

|

Base form

|

1200kg Heavy-duty anti-deformation patented base

|

1800kg Heavy-duty anti-deformation patented base

|

|

|

Optional 4 axis

|

4 axis center height

|

125mm/170mm

|

125mm/170mm

|

|

|

|

4 axis motor power

|

0.75kw/1.2kw

|

0.75kw/1.2kw

|

|

|

|

4 axis system

|

SZGH

|

SZGH

|

|

|

|

4 axis servo

|

SZGH

|

SZGH

|

|

|

Optional 5 axis

|

5 axis center height

|

160mm

|

160mm

|

|

|

|

5 axis motor power

|

0.4kw/0.75kw

|

0.4kw/0.75kw

|

|

|

|

5 axis system

|

SZGH

|

SZGH

|

|

|

|

4 axis servo

|

SZGH

|

SZGH

|

|

The above configuration parameters are for reference,and the configuration listed in the price composition and physical acceptance shall prevail.

Related Products

Why Choose Us

1. Who are we?

We are based in Guangdong, which provides CNC total solutions&Robot arm. Such as

welding Robot arms, painting robot arms, handling robot arms, grinding robot arms, and scara robot, which has independent

technical teams and over 10 years of technical and overseas sales experience. sell to Eastern Europe(20.00%), Mid East(20.00%), Southeast Asia(15.00%), Southern Europe(10.00%), South America(8.00%), North America(5.00%), Western Europe(5.00%), Eastern Asia(4.00%), Central America(4.00%), Northern Europe(4.00%), Africa(3.00%), Domestic Market(2.00%).

technical teams and over 10 years of technical and overseas sales experience. sell to Eastern Europe(20.00%), Mid East(20.00%), Southeast Asia(15.00%), Southern Europe(10.00%), South America(8.00%), North America(5.00%), Western Europe(5.00%), Eastern Asia(4.00%), Central America(4.00%), Northern Europe(4.00%), Africa(3.00%), Domestic Market(2.00%).

2. How can we guarantee the quality?

Always finishing a pre full testing by our professional engineers;

Always final 100% Inspection before shipment.

3. How does your CNC machine work with my production schedule?

Our machine tools use our complete set of CNC systems, and we can also change the corresponding configuration according to your needs, such as turrets, kits, etc., to solve the trouble of debugging and refitting after you receive the goods in advance.

Always finishing a pre full testing by our professional engineers;

Always final 100% Inspection before shipment.

3. How does your CNC machine work with my production schedule?

Our machine tools use our complete set of CNC systems, and we can also change the corresponding configuration according to your needs, such as turrets, kits, etc., to solve the trouble of debugging and refitting after you receive the goods in advance.

4. What ser

v

ices can we provide?

1).Accepted Payment Currency:USD,EUR,CAD,HKD,CNY;

2).Accepted Payment Type:T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash, Escrow;

3).Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,

Korean, Italian, and so on.

1).Accepted Payment Currency:USD,EUR,CAD,HKD,CNY;

2).Accepted Payment Type:T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash, Escrow;

3).Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,

Korean, Italian, and so on.

5.What is control mode for feeding Axes?

Our Normal CNC support Pulse+Direction signals for feeding axes drivers;

Our Modbus CNC support EtherCAT/Powerlink modbus for feeding axes drivers.

6.What is control mode for spindle axes?

There are dual analog voltage outputs(0~10V) for speed control of spindle axis. Our Modbus CNC also support Pulse speed spindle, also can use pulse to control speed of spindle servo system.

7.Does your cnc support ATC function?

Yes, our CNC lathe system can support most of turret, like Eletric turret,servo turret,counting turret,etc;

We can edit special macro program & plc for special turrets also;

And our CNC milling system support Linear type , umbrella type, arm type, turret type tool magazines.

8.Does your cnc support booting logo exchange?

Yes, no problem.

Contact

Hot Searches