- Product Details

- {{item.text}}

Quick Details

-

Material:

-

High Speed Steel

Quick Details

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

YQ

-

Model Number:

-

spline broach

-

Material:

-

High Speed Steel

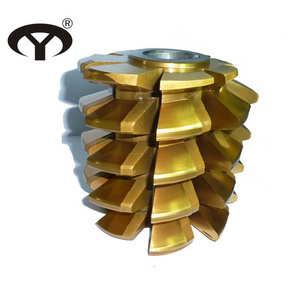

HSS module Internal Gear Broaches with TUV CE

Specification:

|

module |

Width of base tooth space |

No. of teeth |

Overall length |

Broaching length |

|

1 |

1.571 |

12~40 |

430~1000 |

10~120 |

|

1.25 |

1.963 |

550~1120 |

18~120 |

|

|

1.5 |

2.356 |

570~1140 |

||

|

2 |

3.142 |

650~1390 |

||

|

2.5 |

3.927 |

740~1600 |

||

|

3 |

4.712 |

12~30 |

820~1580 |

|

|

3.5 |

5.498 |

12~26 |

850~1670 |

|

|

4 |

6.283 |

12~22 |

920~1520 |

|

|

5 |

7.854 |

12~18 |

1120~1620 |

NOTE :

1. Involute spline broaches with standard pressure angle 30°

2. Fine pitch involute spline broaches of m0.5~m0.8 base circle dia.≥ 6mm can be ordered

3.Involute serration broaches with standard P.A.45°, m0.5~m2.5 can also be ordered.

Material Introduction :

A. W6Mo5Cr4V2 (GB) M2( ASTM), S6-5-2(DIN), SKH51(JIS)

chemical composition:C 0.85, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.00, Mo 4.80 V 1.85

main application:It is widely used for making all kinds of cutters and durability cold-work die

B. W6Mo5Cr4V2Co5 (GB), M35( ASTM), 1.3243(DIN), SKH55(JIS)

chemical composition: C 0.93, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.30, Mo 4.80 V 1.85, Co 5.00

main application:It is often used for making blades with high-speed and great cutting difficulty as it’s good abrasive resistance

W6Mo5Cr4V2(M2),W9Mo3Cr4V(W9),W18Cr4V(W18),W6Mo5Cr4V2Al(M2Al),W6Mo5Cr4V2Co5(M35),W2Mo9Cr4VCo8(M42),W4Mo3Cr4VSi(4341),W4Mo2Cr4VSi(4241)