- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ZHONGTAI

-

Voltage:

-

380V

-

Weight:

-

1800 kg

-

Warranty:

-

1YEAR

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After Warranty Service1:

-

Video technical support

-

After Warranty Service2:

-

Online support

-

After Warranty Service3:

-

Spare parts

-

After Warranty Service4:

-

Field maintenance and repair service

-

Certification:

-

CE

Quick Details

-

Type:

-

Slitting Rewinder

-

Production Capacity:

-

350 m/min

-

Max. workable width:

-

1600mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ZHONGTAI

-

Voltage:

-

380V

-

Weight:

-

1800 kg

-

Warranty:

-

1YEAR

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After Warranty Service1:

-

Video technical support

-

After Warranty Service2:

-

Online support

-

After Warranty Service3:

-

Spare parts

-

After Warranty Service4:

-

Field maintenance and repair service

-

Certification:

-

CE

Product Description

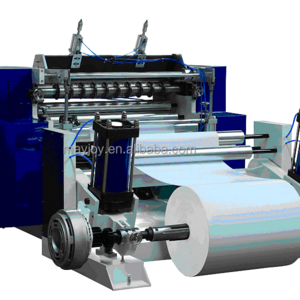

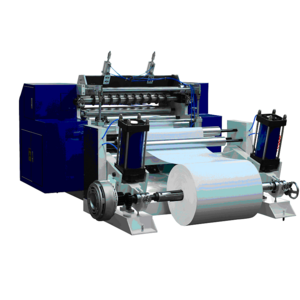

ZTM-A Craft Paper Slitting Machine

1.The machine is mainly used to slit stick paper, craff paper and other kinds of paper

2.Entire machine is controlled by PLC, man-machine interface, screen touch operation

3.Unwinding part adopts imported pneumatic brake control, the rolling diameter is automatically calculated by PLC, to achieve

constant tension control.

4.Traction control is driven by a vector variable frequency motor, to achieve constant linear velocity control, and effectively

cut off interactant tension between rewind and unwind

5.Rewinding part uses the vector frequency conversion motor, to drive magnetic powder clutch, realized by the PLC automatic

cliameter counting auto tension control.

6.Unwinding parts adopts hydraulic power feed, which can save much labour force and shorten time.

7.Auto meter presetting, EPC error correction device is positive to assure the accuracy.

8.The feature of machine is stability, secunlty, efficient.,etc

1.The machine is mainly used to slit stick paper, craff paper and other kinds of paper

2.Entire machine is controlled by PLC, man-machine interface, screen touch operation

3.Unwinding part adopts imported pneumatic brake control, the rolling diameter is automatically calculated by PLC, to achieve

constant tension control.

4.Traction control is driven by a vector variable frequency motor, to achieve constant linear velocity control, and effectively

cut off interactant tension between rewind and unwind

5.Rewinding part uses the vector frequency conversion motor, to drive magnetic powder clutch, realized by the PLC automatic

cliameter counting auto tension control.

6.Unwinding parts adopts hydraulic power feed, which can save much labour force and shorten time.

7.Auto meter presetting, EPC error correction device is positive to assure the accuracy.

8.The feature of machine is stability, secunlty, efficient.,etc

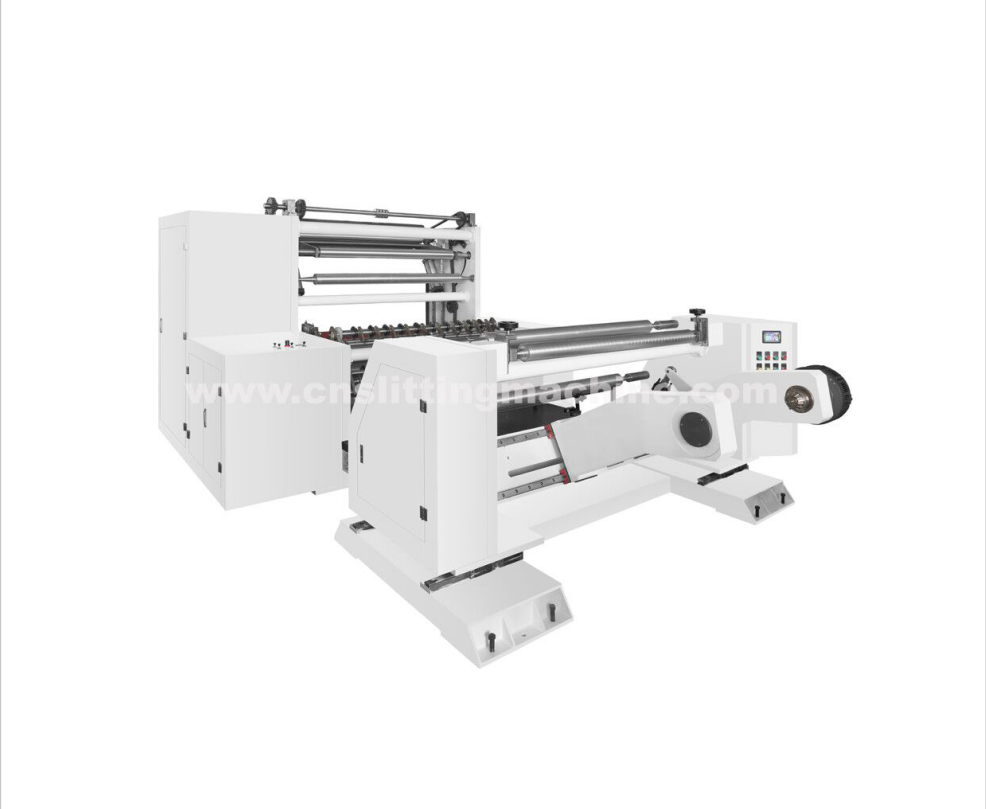

Products Description

|

Max. width of roller

|

1300mm/1600mm

|

|

Max. diameter of raw material

|

1200mm

|

|

Max. diameter of rewinding

|

800-1000mm

|

|

Speed of machine

|

16-350m/min

|

|

Total power

|

20KW

|

|

Overall dimensions

|

2600×4000×1750mm

|

|

Weight of machine

|

3500KG

|

|

Total power

|

12KW

|

|

Weight

|

4500Kg

|

|

overall dimension (L X W X H)

|

2000mm x 4200mm x 1840mm

|

Related Products

Hot Searches