- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

usage:

-

tin can making machine

-

Flooor area:

-

10*12M

-

Worker needed:

-

7-8

Quick Details

-

Application:

-

Chemical, Food, chemical,food

-

Packaging Material:

-

Metal

-

Place of Origin:

-

Jiangxi, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

usage:

-

tin can making machine

-

Flooor area:

-

10*12M

-

Worker needed:

-

7-8

Our company was established since 1994. We specialize in semi-auto and auto metal cans making machines/complete production lines, such as chemical, food, industrial, paint cans making. Our products include: metal sheet cutting machine, can body rolling machines, seam welding machines, flanging machines, sealing machines, moulds and can lid/end making machines,etc.

Tin can saving/money store Box produce Making Machine

1.Main technical parameter:

| Max sheet thickness | 0.5mm |

| Diameter Range | 30-280mm |

| Height Range | Max 330mm |

| Usage | metal cans making complete production line |

| production capacity | 30-35pcs/min |

| floor area needed | 10*12M |

| workers needed | 7-8 |

2,Function:

1)This can making production line is used to make various of metal lap joint cans, such as tea,biscuit,gift ,cake tin box making complete line

2)if customers want to make other size of cans, just need to change the mould of machines

3. More details of each machine

1) R-40 Guillotine shear

| Model | R-40 |

| Max sheet width | 1050mm |

| Max sheet thickness | 0.5mm |

| power | 1.1kw |

| size | 1500 ×1100 ×1200mm |

| weight | 1400kg |

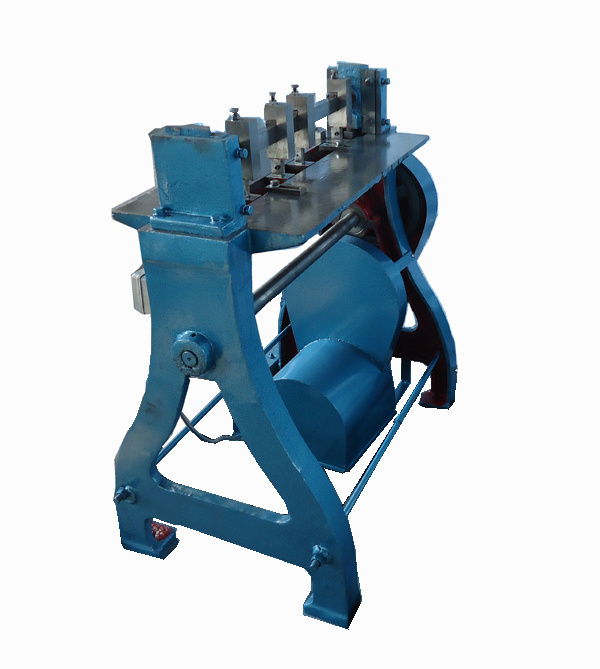

2) C-20 Can-body round-forming machine

| Model | C-20 |

| Max sheet thickness | 0.5mm |

| production capacity | 80-100pcs/min |

| Diameter Range | 50-330mm |

| Height Range | Max440mm |

| Power | 0.75kw |

| Size | 900X700X1000mm |

| Weight | 150kg |

3)Corner cutting machine

| Model | QJ-20 |

| Max sheet thickness | 0.5mm |

| production capacity | 30pcs/min |

| Diameter Range | 330mm |

| Height Range | 330mm |

| Power | 0.55kw |

| Size | 1050X700X1100mm |

| Weight | 300kg |

4) Edging and lock seaming machine

| Model | DP-20 |

| Max sheet thickness | 0.5mm |

| production capacity | 30pcs/min |

| Diameter Range | 50-330mm |

| Height Range | 30-450mm |

| Power | 0.75kw |

| Size | 900X700X1750mm |

| Weight | 600kg |

5)Bottom Flange Machine

| Model | F-4 |

| Max sheet thickness | 0.5mm |

| production capacity | 30pcs/min |

| Diameter Range | Maxmm |

| Height Range | mm |

| Power | 1.5kw |

| Size | 1100X800X1000mm |

| Weight | 400kg |

6)Bottom Flange Machine

| Model | Q4A9 |

| Max sheet thickness | 0.5mm |

| production capacity | 35pcs/min |

| Diameter Range | Max40-191mm |

| Height Range | Max 280mm |

| Power | 1.5kw |

| Size | 100X800X1680mm |

| Weight | 450kg |

4. Applicable for following tin cans

5.our sample case(we specialize in all following tin cans making machines/production lines)

6.Advantage

1).More than 18 years experience and reputation both at home and abroad;

2).Quality Assurance, excellent after service and reasonable price;

3).Reliable and safe to control, easy to operate and maintain;

4).Equipped with human-computer interface and PLC; adopt digital control technology;

5).Full automatic, semi-automatic, and multi mould, suitable for different cans shape and size.

6) Have convenient transportation with airport, railway and port around.

7.customer visit

8.Welcome to visit our company for business negotiation!

when you come and if you demand, We will take you to have a look at the procedure of each cans making production line, then you can know more about our machines.

9.Some of Finished products

10.Machines Package

11. Alibaba assessed supplier certificate