- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.4mm-0.6mm,0.7mm-0.8mm

-

Place of Origin:

-

China

-

Voltage:

-

220v-380v-440v

-

Dimension(L*W*H):

-

Great Variety

-

Weight:

-

1500 kg

-

Feeding width:

-

Other

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Steel Double Layer Roll Forming Machine

-

Color:

-

Clients' Requirements

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

25 M/min

-

Rolling thinckness:

-

0.4mm-0.6mm,0.7mm-0.8mm

-

Place of Origin:

-

China

-

Voltage:

-

220v-380v-440v

-

Dimension(L*W*H):

-

Great Variety

-

Weight:

-

1500 kg

-

Feeding width:

-

Other

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

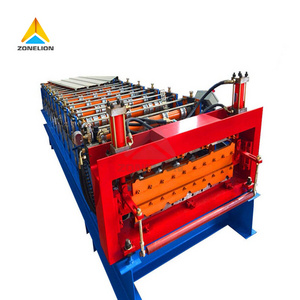

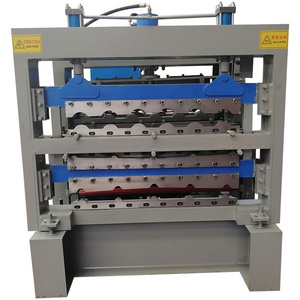

Steel Double Layer Roll Forming Machine

-

Color:

-

Clients' Requirements

roofing sheet double layer roll forming machine | double layer metal roof roll forming machine | metal roof machine | trapezoidal sheet roll forming machine | roofing sheet making machine | wall sheet roll forming machine

Double Layer Roll Forming Machine, available for two profiles (wall and roof panels, etc...) shared one frame, save the cost & space. The two profiles should be double check before making together.

1.This double roll forming machine can produce two different profiles with one machine. Via shared same base frame, un-coiler, PLC control system can much save of your cost.

2.More reasonable forming process design and higher speed; Less roller steps with competitive price.

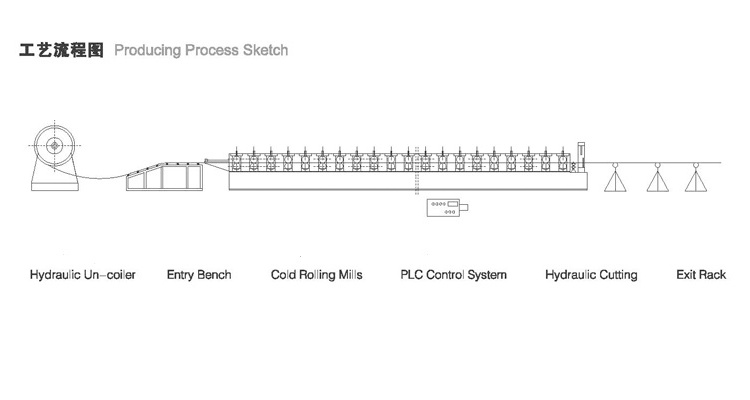

3.The whole line consists of un-coiler, feeding section, double pre-shearing device, roll forming machine with protect guard, post-cut device, PLC control system , and so on.

|

Type |

Roll former for roofing |

|

S hearing Thickness |

Up to Max. 0.8mm |

|

T hickness |

0. 4mm-0.6 mm,0.7mm-0.8mm |

|

Frame Design |

Wall-plate-frame-design / New-stand-frame-design |

|

Roll S tages |

21/22 stages |

|

Material Of Forming Roller |

45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ 75/ Φ 95 mm |

|

Main Motor Power |

11 KW |

|

Max. Line Speed of Roll Former |

10-25 m/min (Higher speed is available, depends on the specification required by the buyer) |

|

Hydraulic Group Power |

5.5 KW |

|

Material of Cutting Blade |

Cr12MOV , hear treatment |

|

Cutting To lerance |

± 1mm |

|

Electric Standard |

380V / 50H z/3PH or as per customer's requirements |

|

Machine Dimensions |

11200 mm ×1750 mm ×1650 mm |

|

Major Color of Machine Painted |

RAL 5015 (Blue) or as per customer ' s requirements |

Machine pictures for reference: