- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

kspack

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

Machine Model

-

Product name:

-

semiautomatic rotary slotter corrugated carton box making machine

-

Rotary cutter diameter:

-

400mm,530mm

-

Painting colour:

-

As requirement

-

Working speed:

-

0-50 pieces/min

-

Way of transmission:

-

chain feeding

-

Over the paper tickness:

-

500mm,600mm,800mm

-

Communication:

-

English/ Turkish/ Russian/ Spanish/German etc

-

Has been exporting country:

-

European / United States / Africa/ South-east Asia etc

-

Machine:

-

carton making machine

Quick Details

-

Applicable Industries:

-

Corrugated box packing machine

-

Voltage:

-

220/380v or according to customer need

-

Power:

-

2.2KW

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

kspack

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

Machine Model

-

Product name:

-

semiautomatic rotary slotter corrugated carton box making machine

-

Rotary cutter diameter:

-

400mm,530mm

-

Painting colour:

-

As requirement

-

Working speed:

-

0-50 pieces/min

-

Way of transmission:

-

chain feeding

-

Over the paper tickness:

-

500mm,600mm,800mm

-

Communication:

-

English/ Turkish/ Russian/ Spanish/German etc

-

Has been exporting country:

-

European / United States / Africa/ South-east Asia etc

-

Machine:

-

carton making machine

Product Description

Specification

|

SIZE

|

PASSING PAPER SIZE

|

Depth of slot (mm)

|

Thickness of pass board

|

Feeding way

|

|

FYQ-2000

|

1850×1470

|

0-50

|

2-11mm

|

Chain

|

|

FYQ-2600

|

2450×1470

|

0-50

|

2-11mm

|

Chain

|

|

FYQ-2000

|

1850×1650

|

0-45

|

2-11mm

|

Chain

|

|

FYQ-2600

|

2450×1650

|

0-45

|

2-11mm

|

Chain

|

Machine introduce

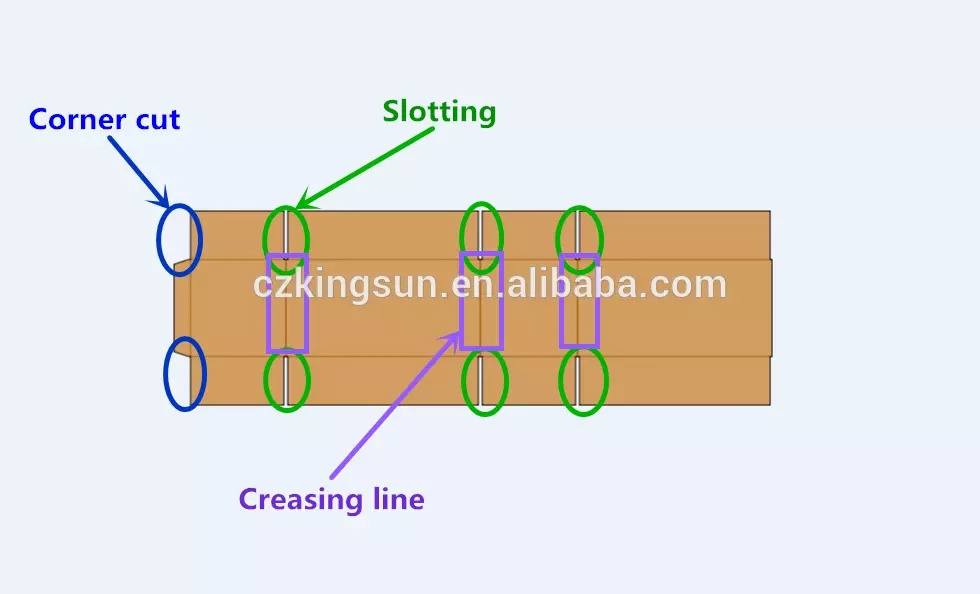

Functions & Characteristics:

This machine is new products researched by our company ,it not only have common rotary

slotting machine’s characteristic, such as easy operation and convenient use ,but had united the

function and characteristic of rotary die-cutter. It don’t need make moulding board, but it can eliminate the phenomenon which have deckle edge and untidy appeared in rotary knive cutted slot .This machine can match with multi-color printing machine according to clients requirement, it reduced the cost of carton factory ,increased the produce quality, it is the economic and perfect machine in modern production.

slotting machine’s characteristic, such as easy operation and convenient use ,but had united the

function and characteristic of rotary die-cutter. It don’t need make moulding board, but it can eliminate the phenomenon which have deckle edge and untidy appeared in rotary knive cutted slot .This machine can match with multi-color printing machine according to clients requirement, it reduced the cost of carton factory ,increased the produce quality, it is the economic and perfect machine in modern production.

Main functions:

1 . Aircraft used spray lubrication of the transmission gear all play a role lubrication.

2. Rubber roller with knives roller gap adjust by manual. The rubber roller lift and down by pneumatic . Rubber adopt roller can shift move 40mm left and right.

3. The speed : max speed 60pcs /max ,work speed : 40-50pcs/min

4. Down knives cushion adopt import rubber cushion , down axle can be lift-lower by pneumatic , not spoil the rubber cushion when axle no-load running and adjusting phase .

5. Down axle can auto movement transversely , rotary die-cutter auto change position , ensure cut mark never reiteration . The rubber cushion use life has greatly enhanced .

6.Up knives adopt import euro rule , it installed on the mould very conveniently , increase the rubber cushion use life , suggestion the customer use it .

7. Adopt posttensioning out the paper , easy dispose of paper trimmings .

8. Die cut adjust use the electrical phase adjust, convenient and quick .

9. Main gear of transmission part thickness is 50mm , it use 45# steel , adopt helical gear driving and processed by high frequency quenching . Auto sprinkle lubricating system, ensure the machine precise and use life .

10. All pressure adjustment by turbine box .

2. Rubber roller with knives roller gap adjust by manual. The rubber roller lift and down by pneumatic . Rubber adopt roller can shift move 40mm left and right.

3. The speed : max speed 60pcs /max ,work speed : 40-50pcs/min

4. Down knives cushion adopt import rubber cushion , down axle can be lift-lower by pneumatic , not spoil the rubber cushion when axle no-load running and adjusting phase .

5. Down axle can auto movement transversely , rotary die-cutter auto change position , ensure cut mark never reiteration . The rubber cushion use life has greatly enhanced .

6.Up knives adopt import euro rule , it installed on the mould very conveniently , increase the rubber cushion use life , suggestion the customer use it .

7. Adopt posttensioning out the paper , easy dispose of paper trimmings .

8. Die cut adjust use the electrical phase adjust, convenient and quick .

9. Main gear of transmission part thickness is 50mm , it use 45# steel , adopt helical gear driving and processed by high frequency quenching . Auto sprinkle lubricating system, ensure the machine precise and use life .

10. All pressure adjustment by turbine box .

Two design slotter knife

Common design

Slotter knife and creasing wheel need to adjust separately one by one when make different size carton box

Advance design

Slotter knife and creasing wheel can adjust at the same time when make different size carton box

Other Related machines

Machine pictures

Hot Searches