- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

600*200*100/150/200

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

weida

-

Voltage:

-

380/415/440V(customerized)

-

Dimension(L*W*H):

-

depends

-

Weight (KG):

-

100000 kg

-

Capacity:

-

30000M3-300000m3/year

-

Color:

-

customized

-

Local Service Location:

-

Indonesia

-

Application:

-

House Building

-

Advantage:

-

Cost Saving,light weight

-

Keywords:

-

Aac Plants

Quick Details

-

Type:

-

Autoclaved aerated concrete block (AAC), lightweight concrete machine

-

Brick Raw Material:

-

concrete,cement,sand,crushed stone,fly ash,

-

Production Capacity (Pieces/8 hours):

-

50000/100000/200000 m3

-

Brick size:

-

600*200*100/150/200

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

weida

-

Voltage:

-

380/415/440V(customerized)

-

Dimension(L*W*H):

-

depends

-

Weight (KG):

-

100000 kg

-

Capacity:

-

30000M3-300000m3/year

-

Color:

-

customized

-

Local Service Location:

-

Indonesia

-

Application:

-

House Building

-

Advantage:

-

Cost Saving,light weight

-

Keywords:

-

Aac Plants

Size Recipe Raw Material How To Make Aerated Autoclaved Concrete Lightweight Brick Making Plant Hebel Block Siporex Aac Machine

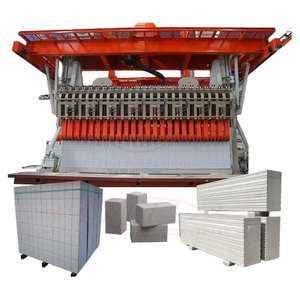

aac block making machine

Aac Plants

AAC Aerated Autoclaved Concrete Block Machine line

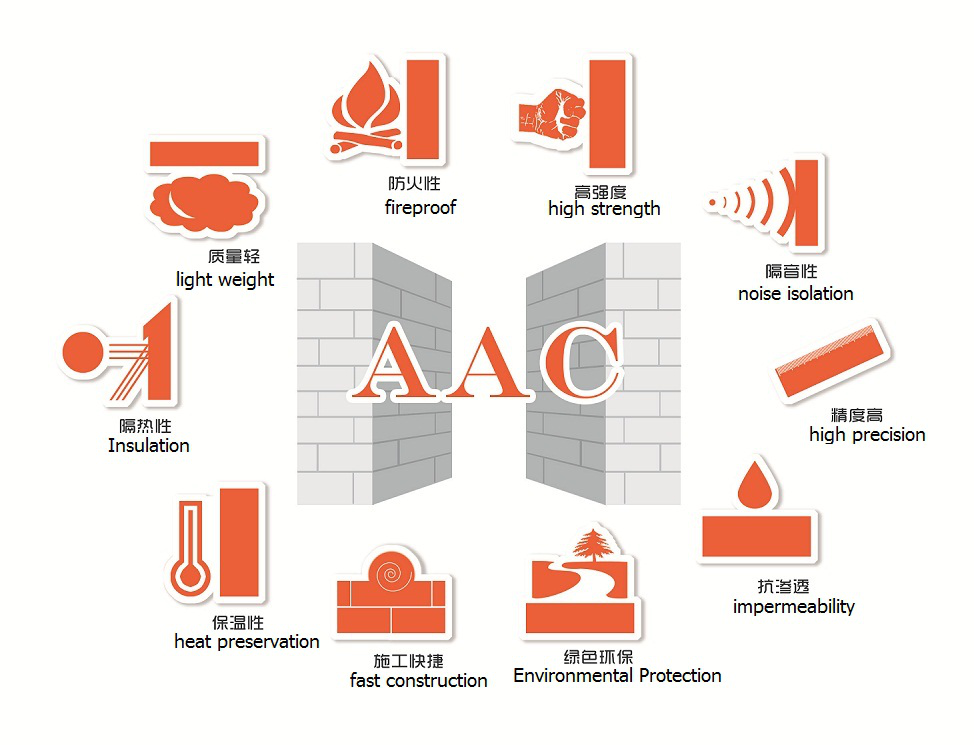

1 AAC block advantage

Introduction

aac block making machine is the light and porous Building Material Machinery . It has light keeping temperature can’t burn and other advantages. It can be made into many kinds of bricks (for example: 600*200*100mm, 600*150*100mm, 600*300*200mm,600*200*150mm), they could be used industry building and common building. They are more and more popular in the world. In future, they will replace the clay brick completely

aac block making machine is the light and porous Building Material Machinery . It has light keeping temperature can’t burn and other advantages. It can be made into many kinds of bricks (for example: 600*200*100mm, 600*150*100mm, 600*300*200mm,600*200*150mm), they could be used industry building and common building. They are more and more popular in the world. In future, they will replace the clay brick completely

(a)Light weight

Aerated concrete density is usually 400-700kgs/m3(according the market production), same as 1/3 of clay brick and 1/5 common concrete. So, use the Light brick can reduce the weight of the build more, and also reduce the beam of roof and pillar press best.Then you can see, it can save the material and cost, it also fighting shaking.

Aerated concrete density is usually 400-700kgs/m3(according the market production), same as 1/3 of clay brick and 1/5 common concrete. So, use the Light brick can reduce the weight of the build more, and also reduce the beam of roof and pillar press best.Then you can see, it can save the material and cost, it also fighting shaking.

(b)Keeping temperature

It has many are porous, the delivery heating coefficient is 0.9-0.22W/ (m.k), the same as 1/4 or 1/5 of clay brick, so it is best materials now in the world.

It has many are porous, the delivery heating coefficient is 0.9-0.22W/ (m.k), the same as 1/4 or 1/5 of clay brick, so it is best materials now in the world.

(c)

good fire resistance and does not emit harmful gases

The main raw materials of aerated concrete are mostly inorganic materials, which itself has thermal insulation performance,therefore, it has good fire resistance, and does not emit harmful gases in case of fire; Because it has a good effect on the steelbars in the building, when the fire of the aerated concrete building, it often only causes damage on the surface, and does notfundamentally damage the structural performance.

(d)with processability

Aerated concrete does not use coarse aggregate, has good machinability, can be sawn, planed, drilled, nailed, and can be bonded ,with appropriate bonding materials, providing favorable conditions for building construction

(e)wide source of raw materials, high production efficiency, low energy consumption

Aerated concrete can be produced with sand, slag, fly ash, tailings, coal gangue and quicklime, cement and other raw materials,can be determined according to the actual conditions of the local variety and production process, and can greatly use industrial waste slag

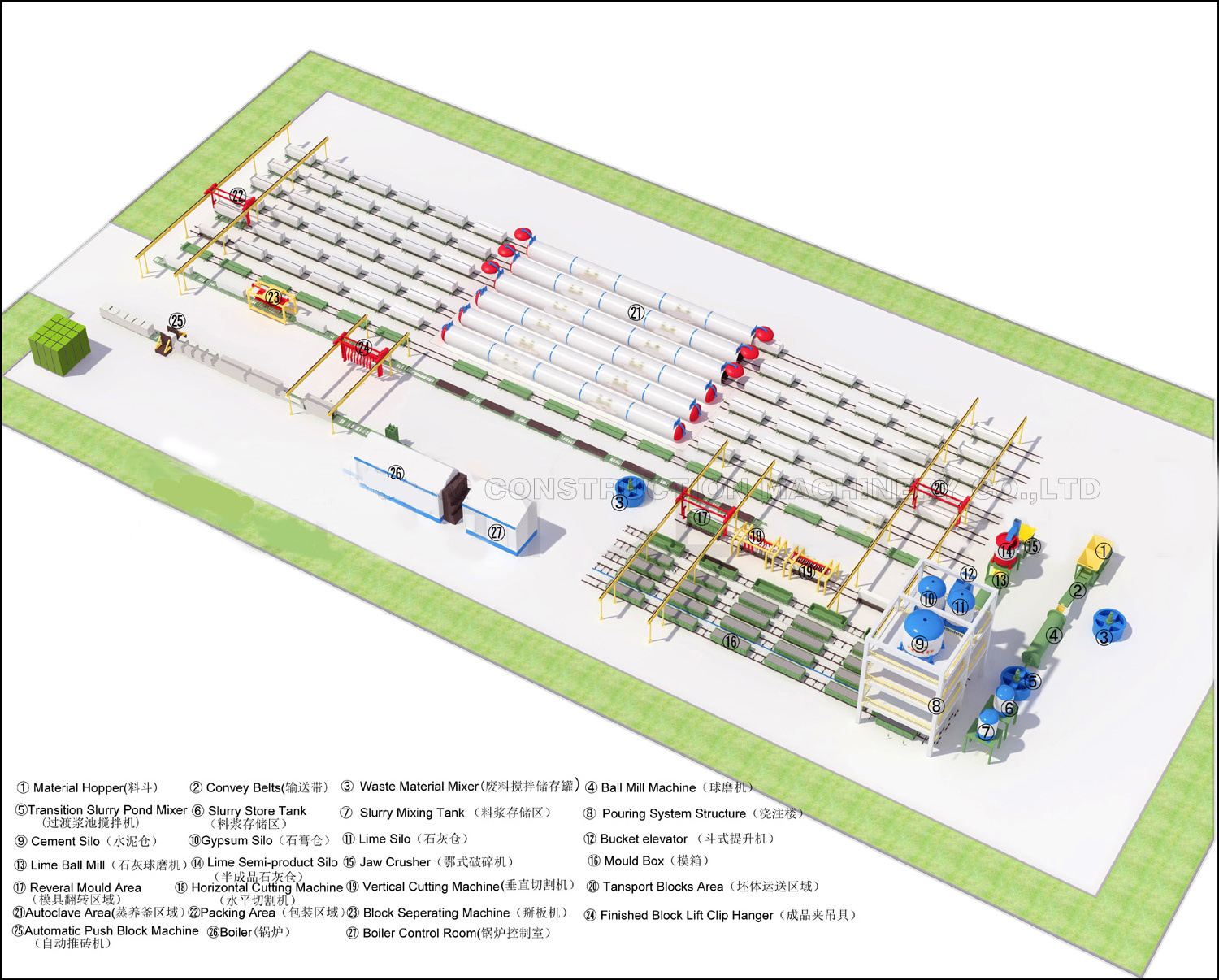

2 Aerated Autoclaved Concrete Block Machine Working proccess

1. Raw material: Store the fly-ash (tailings etc), lime and gypsum after milling to the needed fineness (200 mesh)

2. Mixing the fly ash, cement, lime, gypsum and water in the pouring mixer

3. Promote the slurry temperature to 40-50 degree by steam, and mix with aluminum powder for 1min.

4. Pour the slurry into the mould, and still in the curing room 2-2.5h.

5. Cut it in to needed size by the cutter after the slurry approach the cutting intensity, and place the block on the trolley.

6. Autoclaved curing after the trolley enter into the autoclave (vacuum, rise the pressure, keep the pressure, reduce the

pressure),keeping the constant pressure 1.2 MPa. The whole process needs about 12h.

7. The products out of the autoclave are placed in a stack. We can recycle the scrap and the waste water from the whole

production.

2. Mixing the fly ash, cement, lime, gypsum and water in the pouring mixer

3. Promote the slurry temperature to 40-50 degree by steam, and mix with aluminum powder for 1min.

4. Pour the slurry into the mould, and still in the curing room 2-2.5h.

5. Cut it in to needed size by the cutter after the slurry approach the cutting intensity, and place the block on the trolley.

6. Autoclaved curing after the trolley enter into the autoclave (vacuum, rise the pressure, keep the pressure, reduce the

pressure),keeping the constant pressure 1.2 MPa. The whole process needs about 12h.

7. The products out of the autoclave are placed in a stack. We can recycle the scrap and the waste water from the whole

production.

8

capable for annually producing 30,000m3 to 400,000m3 sand /fly ash AAC blocks

3 Raw materials

1.Siliceous materials: mineral materials with chemical composition dominated by silicon dioxide (SiO2).

Conventional raw materials include: quartz sand tailings, river sand, mountain sand, machine-made sand,

fly ash, marble saw mud, ceramic mud, gold tailings, glass factory tailings, etc

2.Lime:The main component of quicklime is CaO, and the main supply on the market is block lime.

Some areas can supply powdered lime.

3.Cement:According to the different raw materials and strength of the produced autoclaved aerated

concrete blocks and boards, the conventional use grades are 325 # cement, 425 # cement, and 525 #

cement

4.Desulfurization gypsum:Generally, power plant desulfurization gypsum is mainly used, and

phosphogypsum can also be used instead, but the cost of phosphogypsum is much higher than that of power

plant desulfurization gypsum

5.aluminite powder

4 Aerated Autoclaved Concrete Block Machine fly ash dealing process .

Put the sand into ball mill to grinding into the slurry powder, after milling, pump into slurry storage tank

5 Aerated Autoclaved Concrete Block Machine automatic Batching, mixing and pouring process .

The lime, cement will convey by conveyor to the dry powder measure scale to measure separately. The slurry (fly ash or grinded sand) is transported by slurry pump then to the automatic weighing hopper; the dry powder and slurry put into the pouring mixer, then pouring into the mould.

6 Aerated Autoclaved Concrete Block Machine Pre-Curing process .

After slurry pouring into the mould, put the mould box into the curing room with 50~70℃. After 1-2 hours curing, the blocks become solid.

.

7 Aac Block Machine Cutting process.

Using reversal crane carry the into cutting cart position for demould, after demould , The cutting cart will take the block to

two sides cutting,

level cutting machine, vertical cutting, , and remove the top wa

ste and bottom waste

cutting machine is developed based on the traditional cutting machine. It mainly refers to the WIHA technology. Its reducer and control elements are of domestic or international well-known brands, thus ensuring the stability of the machine.

8 Autoclaves for aac blocks .

Finished cutting semi-product move to the front of autoclave grouped, using drag steam trolley into autoclave to steam, it need 6-11 hours , depends on the AAC block or or ALC panels

9 AAC Concrete Block Machine dealing and package .

Finished fly ash aac block product out of autoclave, by separating machine to separate layer by layer.

And using finished block carry clamp the finished product to package line on wooden pallets, after package, then by forklift transport the finished products to piled yard according to specifications to stack.

And using finished block carry clamp the finished product to package line on wooden pallets, after package, then by forklift transport the finished products to piled yard according to specifications to stack.

Packing & Delivery

1 Genera fly ash AAC block plant equipment transport with 40 HQ container.

2. Ball mill transport with 40 OT or 40 FR according the size.

3. Autoclave transport on deck of ship.

4. Cutting machine usually transport with 40 FR or on deck of ship.

2. Ball mill transport with 40 OT or 40 FR according the size.

3. Autoclave transport on deck of ship.

4. Cutting machine usually transport with 40 FR or on deck of ship.

Certifications

Company Profie

FAQ

Q1. What is the advantage about your company?

A1.

Weida Machinery's professional sales team and offices

established across the country allow you to be familiar with the latest national and regional policies and

industry trends, allowing you to take the initiative in early inspection and equipment selection.

In the early stages of the project, we provide professional project feasibility reports, technical

solutions, and other related materials, fully cooperating and doing our best to serve you. Q2. Why should I choose your products? A2. Weida Machinery is a "world-class supplier of autoclaved aerated concrete whole line system

services". We have a professional team to take you into the aerated concrete industry. Early market

research is crucial for project development. Q3. Any other good service your company can provide? A3. The service concept of the "butler style service" company is to provide tracking services such as

factory data analysis, process planning, and raw material analysis before equipment sales. In equipment

sales, comprehensive services in civil engineering, process, training, and management are provided. After

equipment sales, it is a one-stop and endless service model.

established across the country allow you to be familiar with the latest national and regional policies and

industry trends, allowing you to take the initiative in early inspection and equipment selection.

In the early stages of the project, we provide professional project feasibility reports, technical

solutions, and other related materials, fully cooperating and doing our best to serve you. Q2. Why should I choose your products? A2. Weida Machinery is a "world-class supplier of autoclaved aerated concrete whole line system

services". We have a professional team to take you into the aerated concrete industry. Early market

research is crucial for project development. Q3. Any other good service your company can provide? A3. The service concept of the "butler style service" company is to provide tracking services such as

factory data analysis, process planning, and raw material analysis before equipment sales. In equipment

sales, comprehensive services in civil engineering, process, training, and management are provided. After

equipment sales, it is a one-stop and endless service model.

Hot Searches