- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

90 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

xingle

-

Voltage:

-

220v

-

Power (kW):

-

0.55 kW

-

Feature:

-

easy to clean

-

Color:

-

Steel True Colors

-

Advantage:

-

pollution-free

-

Packing:

-

Wooden Case

-

Function:

-

Mixing Raw Material

-

Application scope:

-

Chemical Cosmetic Food

-

Homogenizer:

-

Mixer Homogenizer

-

Control:

-

Electronic Control

-

Type:

-

Rotary Typing Mixer

Quick Details

-

Barrel Volume (L):

-

5

-

Max. Loading Volume (L):

-

2.5 L

-

Range of Spindle Speed(r.p.m):

-

1 - 15 r.p.m

-

Weight (KG):

-

90 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

xingle

-

Voltage:

-

220v

-

Power (kW):

-

0.55 kW

-

Feature:

-

easy to clean

-

Color:

-

Steel True Colors

-

Advantage:

-

pollution-free

-

Packing:

-

Wooden Case

-

Function:

-

Mixing Raw Material

-

Application scope:

-

Chemical Cosmetic Food

-

Homogenizer:

-

Mixer Homogenizer

-

Control:

-

Electronic Control

-

Type:

-

Rotary Typing Mixer

Product Description

Specification

SWH-5L, 10L, 15L, 20L, 30L, 50L, 100L, 200L Three Dimensional Mixer For food Plant

Main application:

This machine is mainly used in food industry and also the chemical, electronic, plastic and metallurgical industries. When the machine is working, the mixing barrel runs in multiple directions. In the mixing process of various materials, the effect of flow and diffusion is increased. Compared to general mixer, the 3D mixer avoids the segregation and accumulation of material specific gravity due to centrifugal effect, so it can provide an excellent mixing effect. It is widely used in material mixing in the industries of food, chemical and so on.

Operating principle:

1. The mixing barrel runs in multiple directions, so it can mix the materials much more evenly than other general mixers. It has a lower error of the food content than other general mixers.

2. The maximum charging volume of the SBH series mixer is more than twice that of the general mixers (the maximum capacity of the general mixer is 40% of the barrel volume).

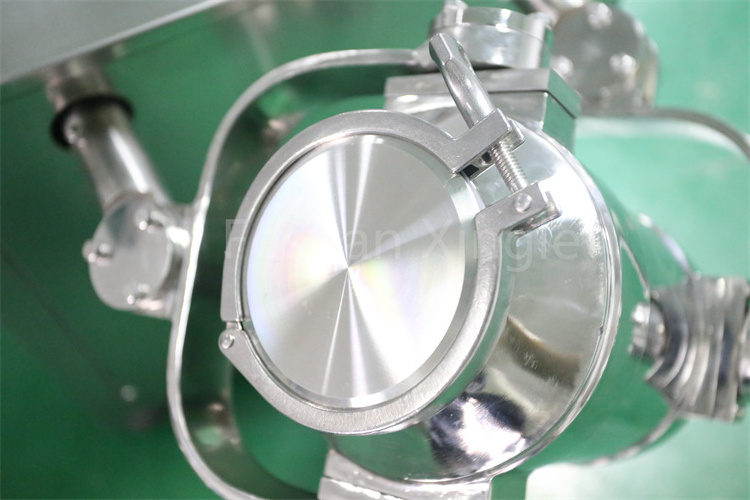

3. The mixing barrel of the SBH series three-dimensional motion mixer is unique in design. The inner wall of the mixing barrel is finely polished, and there is no dead corner. It will not contaminate the materials.

4. The material is poured out due to its own weight. There will be no leftover materials. This machine has the advantages of no pollution, easy discharge, no accumulation, and easy cleaning.

5. The materials are mixed in a sealed environment and will not pollute the working environment.

This machine is mainly used in food industry and also the chemical, electronic, plastic and metallurgical industries. When the machine is working, the mixing barrel runs in multiple directions. In the mixing process of various materials, the effect of flow and diffusion is increased. Compared to general mixer, the 3D mixer avoids the segregation and accumulation of material specific gravity due to centrifugal effect, so it can provide an excellent mixing effect. It is widely used in material mixing in the industries of food, chemical and so on.

Operating principle:

2. The maximum charging volume of the SBH series mixer is more than twice that of the general mixers (the maximum capacity of the general mixer is 40% of the barrel volume).

3. The mixing barrel of the SBH series three-dimensional motion mixer is unique in design. The inner wall of the mixing barrel is finely polished, and there is no dead corner. It will not contaminate the materials.

4. The material is poured out due to its own weight. There will be no leftover materials. This machine has the advantages of no pollution, easy discharge, no accumulation, and easy cleaning.

5. The materials are mixed in a sealed environment and will not pollute the working environment.

Main Parameter

|

Model

|

SWH-5L

|

SWH-10L

|

SWH-15L

|

SWH-20L

|

|

Mixing Bucket Volume (L)

|

5

|

10

|

15

|

20

|

|

Max. Charging Quantity (L)

|

2.5

|

5

|

8

|

16

|

|

Spindle Speed (m/min)

|

0-15

|

0-15

|

0-12

|

0-12

|

|

Motor (kW)

|

0.55

|

0.55

|

0.55

|

0.55

|

|

Weight (kg)

|

90

|

105

|

115

|

130

|

|

Model

|

SWH-30L

|

SWH-50L

|

SWH-100L

|

SWH-200L

|

|

Mixing Bucket Volume (L)

|

30

|

50

|

100

|

200

|

|

Max. Charging Quantity (L)

|

22

|

40

|

80

|

160

|

|

Spindle Speed (m/min)

|

0-12

|

0-12

|

0-12

|

0-12

|

|

Motor (kW)

|

0.75

|

1.5

|

2.2

|

4

|

|

Weight (kg)

|

180

|

300

|

700

|

1500

|

Foshan Xingle Machinery Equipment Co., Ltd. is a professional manufacturer and supplier of machinery and enjoys a good reputation in local and global markets. We are specialized imachines including pulverizes, mixer, Granulator, coating machine, counting machine, blister packaging machine, cartoning machine, labeling machine,ampoule filling and sealing machine, oral liquid filling production line, ampoule printing machine, suppository machine, we can undertake concept design, process design turnkey project and so on.

High-quality machinery, competitive prices and sincere customer service are highly appreciated by customers. Our machines have been exported to many countries in the world, North America, Europe, Australia, South America, Southeast Asia and Africa. In order to provide the best quality, the products we manufacture comply with GMP, cGMP and other international standards.

Q: Why choose us?

A: We have been supplying machines including blender,counting machine,blister packing machine etc for over 14 years. What we offer is a good product at a reasonably price.

Q: Can I customize the product?

A: Abosolutely. We can customize machine according to your need. Also we can the package the products according to your request.

Q:What's the delivery time?

A:if machine we have in stock we ship in 7 days ,if not have in stock producing time it is around 15- 45days depends on different machine.

Q: Can I customize the product?

A: Abosolutely. We can customize machine according to your need. Also we can the package the products according to your request.

Q:What's the delivery time?

A:if machine we have in stock we ship in 7 days ,if not have in stock producing time it is around 15- 45days depends on different machine.

Hot Searches