- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CHOZEN TECH

-

Model Number:

-

CZPP-P

-

Type:

-

Virgin Material

-

Sample:

-

Available

-

Material:

-

Polypropelene

-

Color:

-

White, black, grey or customize

-

MOQ:

-

1 KG

-

Product Name:

-

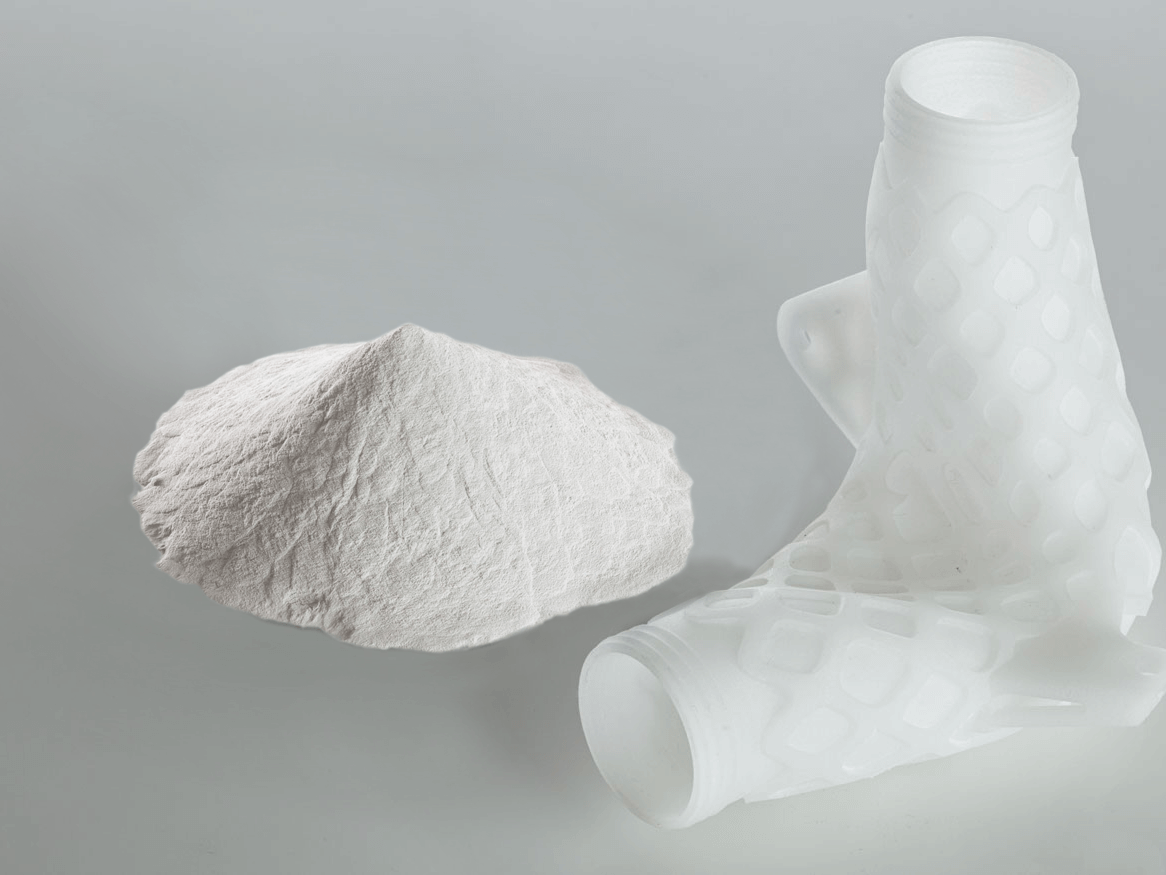

PP powder for 3D printing

-

Package:

-

CUSTOMEZED

-

3D printer type:

-

SLS, MJF

-

Certificate:

-

REACH ROHS

Quick Details

-

color:

-

White, Grey, Black, etc

-

Shape:

-

Fine Powder

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CHOZEN TECH

-

Model Number:

-

CZPP-P

-

Type:

-

Virgin Material

-

Sample:

-

Available

-

Material:

-

Polypropelene

-

Color:

-

White, black, grey or customize

-

MOQ:

-

1 KG

-

Product Name:

-

PP powder for 3D printing

-

Package:

-

CUSTOMEZED

-

3D printer type:

-

SLS, MJF

-

Certificate:

-

REACH ROHS

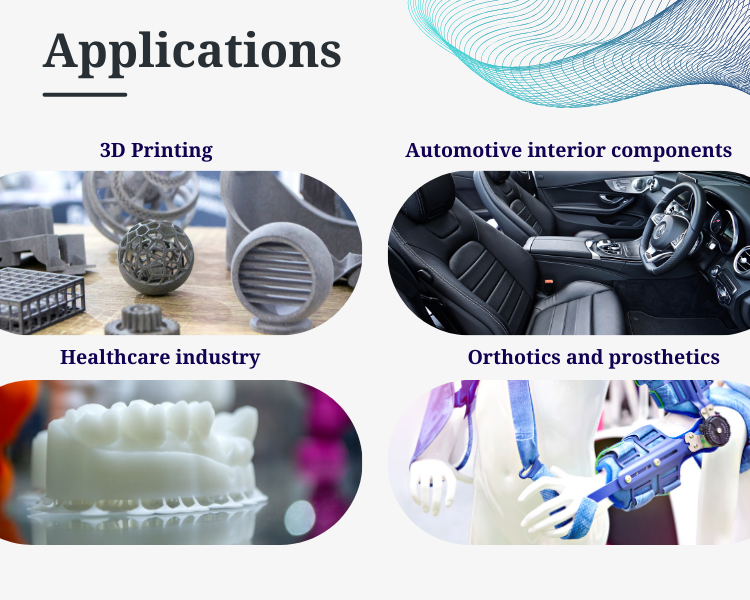

PP powder harnesses the advantageous properties of polyolefins for use in Powder Bed Fusion (PBF) technologies, enabling the swift production of tailored and functional parts for serial manufacturing. Characterized by its well-known resilience, this powder offers exceptional chemical resistance, ductility, and media tightness. Our proprietary formula elevates these benefits even further. Unlike the widely used polyamides, PP distinguishes itself with superior plasticity, enhanced elongation at break, increased durability, and minimal moisture absorption. Its considerable rigidity renders PP particularly suitable for technical endeavors and the creation of sturdy 3D printed components, ranging from initial prototypes to fully functional parts. Additionally, PP presents a cost-effective alternative to the frequently utilized PA12, positioning it as an appealing option for broadening the scope of 3D printing applications and production scales.

Mechanical Properties

|

Ultimate Tensile Streng th |

29 MPa |

4206 psi |

ASTM D 638-14 Type 1 |

|

Tensile Modulus |

1640 MPa |

239 ksi |

ASTM D 638-14 Type 1 |

|

Elongation at Break (X /Y) |

34 % |

34 % |

ASTM D 638-14 Type 1 |

|

Elongation at Break (Z) |

16 % |

16 % |

ASTM D 638-14 Type 1 |

|

Flexural Strength |

37 MPa |

5366 psi |

ASTM D 790-17 |

|

Flexural Modulus |

1330 MPa |

192 ksi |

ASTM D 790-17 |

|

Notched Izod |

31 J/m |

0.58 ft-lb/in |

ASTM D256-10 |

Thermal Properties

|

Heat Deflection Temp. @ 1.8 MPa |

58 °C |

136 °F |

ASTM D 648-16 |

|

Heat Deflection Temp. @ 0.45 MPa |

113 °C |

235 °F |

ASTM D 648-16 |

|

Vicat Softening Temperature |

132 °C |

269 °F |

ASTM D 1525 |

Other Properties

|

Moisture Content (powder) |

0.06 % |

0.06 % |

ISO 15512 Method D |

|

Water Absorption (printed part) |

0.25 % |

0.25 % |

ASTM D570 |