- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

dzx

-

Weight:

-

5 KG

-

Working Temperature Range:

-

0 - 500 ℃

-

Size:

-

Customized

-

Cable Wires:

-

3~5 wires

-

MOQ:

-

10 pcs

-

Delivery Time:

-

7-20 Days

-

Application:

-

Air Heating

-

Voltages available:

-

220V 380V

-

Power:

-

Customized 30W-3000W

-

Advantage:

-

High Speed Heating

-

Shape:

-

Ring Coil

-

thermicouple Type:

-

K type Jtype

Quick Details

-

Type:

-

Coil Heater

-

Power Source:

-

Electric

-

Voltage:

-

36V DC 12V 120V 380v 220V DC 24V AC 110V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

dzx

-

Weight:

-

5 KG

-

Working Temperature Range:

-

0 - 500 ℃

-

Size:

-

Customized

-

Cable Wires:

-

3~5 wires

-

MOQ:

-

10 pcs

-

Delivery Time:

-

7-20 Days

-

Application:

-

Air Heating

-

Voltages available:

-

220V 380V

-

Power:

-

Customized 30W-3000W

-

Advantage:

-

High Speed Heating

-

Shape:

-

Ring Coil

-

thermicouple Type:

-

K type Jtype

Products Description

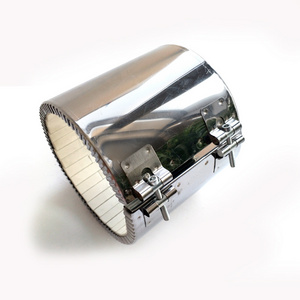

industrial high temperature electric spring nozzle brass Hot Runner coil copper heater

Hot Runner Coil Heaters are made of nickel chrome resistance wire placed inside chrome nickel steel tube filled with MgO powder and compacted for faster and efficient heat transfer. The heaters are annealed to acquire malleability for bending into any shape. Hot runner heaters with built in thermocouple are also available. Hot runner bushes are produced with hot runner heaters of different cross section with inner brass and outer stainless steel cover.

|

Sheath Material

|

ss304ss321ss316

|

|

Heating conductor compound

|

NiCr8020

|

|

Maximum Sheath Temperature

|

750°C

|

|

High voltage strength(cold)

|

800V-AC

|

|

Voltage

|

AC220V~240V

|

|

Power tolerance(cold)

|

±0.05

|

|

Length Tolerance (Straight)

|

±5%

|

|

Insulation resistance(cold) an1000V-DC

|

≥100MΩ

|

|

Leakage current(cold)

|

600V≤0.5MA

|

|

Max.surface load on heater sheath

|

10W/cm

|

|

Miimum bending fadius(internal) heated

|

3mm

|

|

and unheated zone

|

|

Description of Coil Heater:

1) Spring coil heater is made of nickel chrome resistance wire placed inside chrome nickel steel tube that is filled with MgO powder.

2) Spring coil heater is also known as high performance tubular heaters or cable heaters.

2) Spring coil heater is also known as high performance tubular heaters or cable heaters.

3) Spring heater can be produced with or without built in thermocouples.

3) Spring coil heater is widely used in heating engineering, mold, plastic industry, including the transfer machinery, medical equipment, casting process, welding, heat treatment process and many other industries and fields

3) Spring coil heater is widely used in heating engineering, mold, plastic industry, including the transfer machinery, medical equipment, casting process, welding, heat treatment process and many other industries and fields

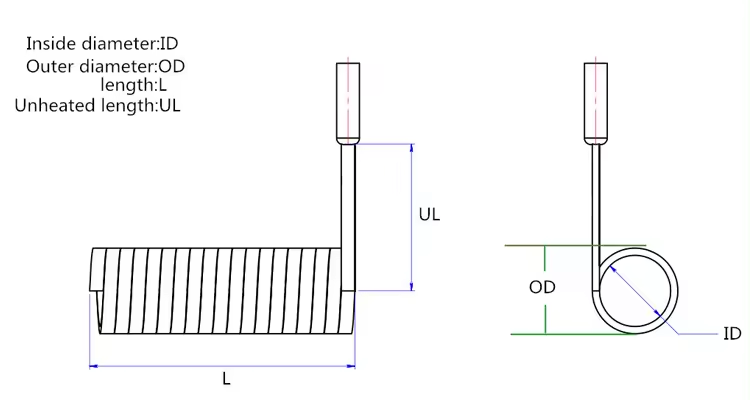

Specification

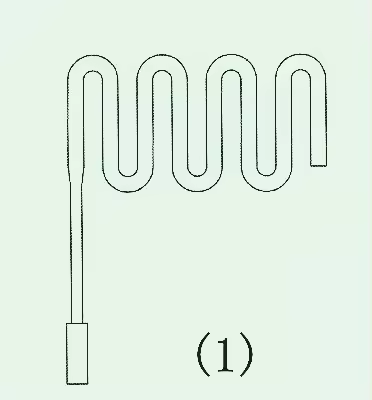

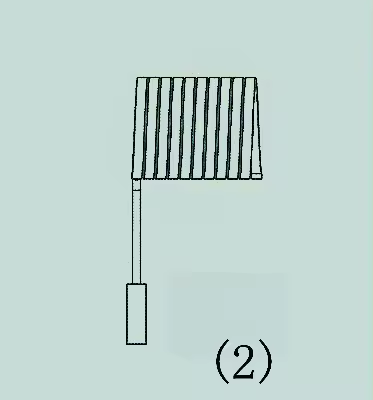

Coiling schemes

Coil exits

Our Advantages

1 We use German Nichrome high quality heating wire to improve heating effect and service life

2 We use imported high-purity Mgo rods, which have good thermal conductivity, are not easy to get wet, have high density, can better

3 The heater is uniformly heated as a whole, which can uniformly heat the mold nozzle, make the mold sol smoother, effectively improve production efficiency, and reduce the difficulty of adjusting the parameters of the injection molding machine caused by unstable heating.

wrap the heating wire, and are less prone to break the metal shell.

4 The lead part adopts imported high temperature resistant wires to reduce the short circuit of the heater caused by the damaged wire sheath.

Details Images

Company information

About Us

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3,

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

What is your contact information?

Skype/Whatsapp/Wechat:+86-18961410953

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

Hot Searches