- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fect

-

Voltage:

-

380V

-

Power:

-

19KW

-

Dimension(L*W*H):

-

9200*3300*1900mm

-

Weight:

-

7000 kg

-

Marketing Type:

-

pulp moulding machine

-

Product name:

-

biodegradable disposable food container making machine for lunch box

-

keyword:

-

pulp moulding machine

-

Capacity:

-

5500-6000pcs/hr

-

Mould platen size(mm):

-

920*920

-

Moving distance of hot-pressing mold:

-

400 (mm)

-

Minimum shut height of hot-pressing mold:

-

120 (mm)

-

Up forming platen moving distance:

-

750 (mm)

-

Down forming platen moving distance (mm):

-

250 (mm)

-

Application:

-

paper lunch box,paper plate,paper cover

-

Control method:

-

PLC, touch screen

Quick Details

-

Production Capacity:

-

other

-

Product Type:

-

Paper lunch box making Machine

-

Processing Type:

-

Paper lunch box making Machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fect

-

Voltage:

-

380V

-

Power:

-

19KW

-

Dimension(L*W*H):

-

9200*3300*1900mm

-

Weight:

-

7000 kg

-

Marketing Type:

-

pulp moulding machine

-

Product name:

-

biodegradable disposable food container making machine for lunch box

-

keyword:

-

pulp moulding machine

-

Capacity:

-

5500-6000pcs/hr

-

Mould platen size(mm):

-

920*920

-

Moving distance of hot-pressing mold:

-

400 (mm)

-

Minimum shut height of hot-pressing mold:

-

120 (mm)

-

Up forming platen moving distance:

-

750 (mm)

-

Down forming platen moving distance (mm):

-

250 (mm)

-

Application:

-

paper lunch box,paper plate,paper cover

-

Control method:

-

PLC, touch screen

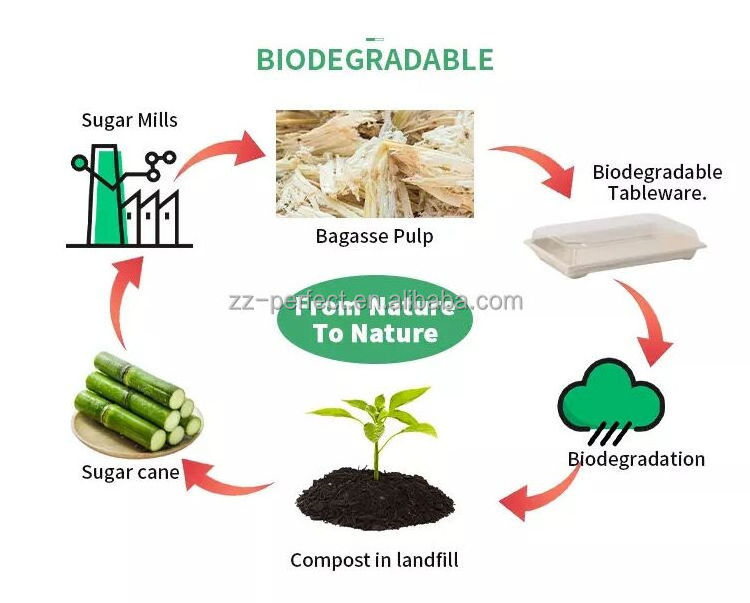

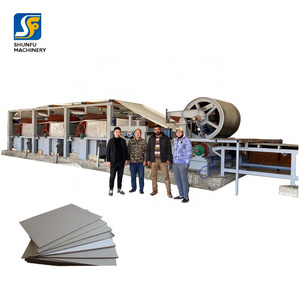

The machine line mainly produces tableware plate products, and other higher quality both smooth side of packages products, like electrical inner packages, elegant mask,etc. It is for high demand of packages products machine line, which the process of drying, hot-pressing, forming will be automatic continuous completed on the same machine,with high automatic of PLC+ Touch screen control whole process.

♦Application♦

It’s mainly used for high quality pulp molded products. Such as dishware, artware, high quality industrial package.This type of production line is constituted by a hydrapulper system, a fully automatic thermoforming machine(forming/drying/pressing integrative machine), and corollary equipments.

♦Technical parameters♦

|

Model |

PF-Z900 |

|

Total power |

194.4KW |

|

Capacity |

5500-6000pcs/hr |

|

Mould platen size ( mm) |

92 0* 92 0 |

|

Moving distance of hot-pressing mold ( mm) |

400 |

|

Minimum shut height of hot-pressing mold ( mm) |

120 |

|

Up forming platen moving distance (mm) |

750 |

|

Down forming platen moving distance (mm) |

250 |

|

Voltage |

380V |

|

Pressure of compressed air |

minus 0.045 - minus 0.055Mpa |

|

Control method |

PLC , touch screen |

♦Features♦

1. High efficiency production line. The whole working processes of forming, drying and hot-press shaping completed in one machine with high degree of automation.

2. Using international standard brand control accessories, with technical making high level, the machine has long stability performance and low malfunction.

3. It has wide range of application, and it can produce various specifications and different thickness of production by changing the moulds.

♦Details♦

1.Bagasse pulp wood paper pulp hydraulic pulping process

2. fully automatic bagasse tableware machine(PLC+Touch screen)

3 . Edge cutting for the bagasse pulp plates

♦ Flow Chart ♦

-

Package Detail Wooden case/fully automatic biodegradable disposable food container making machine for lunch box Package Seize 2960*1310*1325mm Gross Weight 2100kgs