- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

27.12KHz

-

Welding Area:

-

depende on the moulds

-

Dimensions:

-

customized

-

Usage:

-

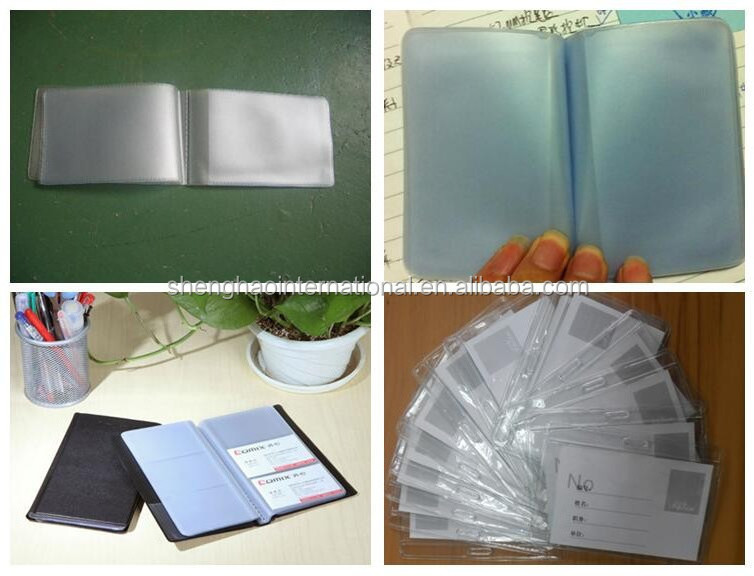

leather embossing, Plastic, PVC welding, PVC card sleeve welding, PU, Plastic welding, embossing...

-

Weight (KG):

-

450 KG

-

Power (kW):

-

5

-

Product:

-

High Frequency plastic card sleeve making machine

-

Rectifier:

-

Sillcon Diode

-

Output Power:

-

5KW,8kw of HF Plastic Welder

-

Driven Type:

-

Pheumatic for HF welding mchine

-

Operation:

-

Foot Pedal of HF welding mchine

-

Oscillation Tube:

-

7T69RB

-

Certificate:

-

CE ISO Certificate

-

Product name:

-

High Frequency Welding Machine

-

Package:

-

Wooden Case

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CHENGHAO MACHINERY

-

Voltage:

-

220V/380V 3P 50/60Hz

-

Frequency:

-

27.12KHz

-

Welding Area:

-

depende on the moulds

-

Dimensions:

-

customized

-

Usage:

-

leather embossing, Plastic, PVC welding, PVC card sleeve welding, PU, Plastic welding, embossing...

-

Weight (KG):

-

450 KG

-

Power (kW):

-

5

-

Product:

-

High Frequency plastic card sleeve making machine

-

Rectifier:

-

Sillcon Diode

-

Output Power:

-

5KW,8kw of HF Plastic Welder

-

Driven Type:

-

Pheumatic for HF welding mchine

-

Operation:

-

Foot Pedal of HF welding mchine

-

Oscillation Tube:

-

7T69RB

-

Certificate:

-

CE ISO Certificate

-

Product name:

-

High Frequency Welding Machine

-

Package:

-

Wooden Case

High Frequency plastic card sleeve making machine

HF Welder

is designed specifically for production of small and large format tensile structures, membranes, tarpaulin, tents, oil booms, truck covers, swimming pool liners & covers, airline hangars, large billboards, fast doors, side curtains, etc. This basic design machine can be fitted with special impulse electrode for welding nonHF weldable fabrics made of PE and PP, as well as FlexEL ‘soft’ multilayer welding electrode and curved HF electrodes for sealing round window profiles made of clear PVC and any other shapes requiring precision welding.

HF Welder

is designed specifically for production of small and large format tensile structures, membranes, tarpaulin, tents, oil booms, truck covers, swimming pool liners & covers, airline hangars, large billboards, fast doors, side curtains, etc. This basic design machine can be fitted with special impulse electrode for welding nonHF weldable fabrics made of PE and PP, as well as FlexEL ‘soft’ multilayer welding electrode and curved HF electrodes for sealing round window profiles made of clear PVC and any other shapes requiring precision welding.

1. Steady frequency:

High frequeny blister packing machine strictly adopts industrial wave band 27.12/40.68 MHz according to the provision of nations "radio interference committee"(CISPR) with steady frequency device and prevent the leak of magnetism, have no interference about the outside environment.

2. Spark restrains system:

High frequency blister packing machine has high sensitive Spark restraint electro-circuit can check out the imbalance current which can bring spark and cut it off, meanwhile alert the operator.

3. Vibrate current setting:

Hgh frequency blister packing machine the output can be adjusted by adjuster according to thickness of material and the size of products, which ensure the quality of welding and promote production.

4. Security protection:

High frequency blister packing machine has security protection system of exceed voltage and electric current.

Application range:

High frequency welding machine for Shoes upper, trademark, Sticker, raincoat, Umbrella, leather bag, Hand bad, beach bag, Stationery, nameplate, Air-stuffing toy, waterbed, leather products and PVC products.

About us:

We are the leading manufacture that specialize in designing and manufacturing different kinds of HighFrequency Welding machine. With the experience of more than 10 years, manufacturing according to theISO 9001: 2004 and CE quality control system guidelines. We help our customer develop special H. F machine for the application and OEM service is offered.

Equipment advantages:

High-sensitivity spark-proof device

High frequency blister welding machine

High efficiency

Strong electric power output

|

Model |

CH-D5 |

CH-D8 |

|

Power Output |

5000W |

8000W |

|

Voltage |

50/60Hz AC380V/220V 3P(Customize) |

|

|

Power Input |

8.5KVA |

15KVA |

|

Rectifier |

Silicon Diode |

Silicon Diode |

|

Oscillation Frequency |

27.12Mhz |

27.12Mhz |

|

Oscillation Tube |

7T85RB |

7T69RB |

|

Anti-Spark Thyratron Tube |

Nl-5557 |

NL-5557 |

|

Max Pressure |

800KG |

800KG |

|

Gap of Electrodes |

160MM |

160MM |

|

Dimension of Upper Board |

160*400MM |

160*400MM |

|

Dimension of Lower Board |

350*500MM |

350*500MM |

|

Overall Dimension |

1790*1140*1500mm |

1790*1140*1500mm |

|

Net Weight |

450kg |

500kg |

|

Packing Dimension |

1810*1160*1530mm |

1810*1160*1530mm |

|

Packing Weight |

480KG |

530KG |

|

CBM |

3.6 |

3.6 |

|

Ps: Machine design and power can be customize according to your products production. |

||

3.Basic operating principles:

This machine is a high frequency device, whose self-exited oscillator of the electron tube can produce high frequency electromagnetic field. And the plastic to be processed is in the high frequency electromagnetic field between the upper and low electrode. When its interior molecules are polarized and produce heat automatically by mutual movement and friction, it will be welded with the pressure of the die.

4.Machine maintenance:

a. Add oil lubricant in each function parts every several days, and often wipe cleanly.

b. To cleanout and lubricate each parts of the machine every half year, clear away the dust in the parts of transformer, high voltage capacitor, blower fan and Resonant Cavity.

c. f the aluminium pan of the output adjusting capacitor and the capacitor in the side of resonant cavity, was ablated by caustic caused by dust or eyewinker, the caustic surface should be repair flatly and smoothly in time.

5.Notice:

A.When new machine is on use or replace the new electron tube, after bootstrap, pls make the electron tube warm up about 15 minutes, then put into operation, to reduce the warming up time gradually within one week, so as to promise and extend the service life of the electron tube.

B.When operation, it is prohibited to make the anode and cathode immediate contact, to avoid the work damage caused by the short circuit

C.When welding, ban to touch the electrode, conducting strip and mold, to avoid burning skins.

D.It’s the high-voltage electrode in the machine, when maintance and reparing, make sure to pull down the knife switch to ensure safety.

Profile:

We are the leading manufactures who specialize in producing high frequency plastic welding machine, HF induction heating machine, HF preheating machine, ultrasonic welding machine, blister packing machine, shrink packaging machines, vacuum packagingmachines, machine accessories and molds etc.

With the experience of more than 20 years, our company's products have passed ISO 9001:2000, SGS and CE certification of EU market.

Pre-sale services:

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

4. Personal call or visit are warmly welcome.

Sale of services:

1. We promise honest and fair, it's our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1.Where to buy our products for one year warranty and life long maintenance.

2.24-hour telephone service.

3. A large stock of components and parts, easily-worn parts