- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Biomass Steam Bioler

-

Application:

-

Rice Mill

-

Material:

-

Thicker Stainless Steel

-

Function:

-

Single Heating

-

Application Field:

-

Industrail

-

Capacity:

-

Steam Boiler 1t/h

-

Boiler Structure:

-

Horizontal Three Return Fire Tube Boiler

-

Rated steam temperature:

-

170/185 Degree

Quick Details

-

Place of Origin:

-

Henan, China

-

Dimension(L*W*H):

-

customized as steam boiler

-

Weight:

-

customized as per steam boiler

-

Product name:

-

Biomass Steam Bioler

-

Application:

-

Rice Mill

-

Material:

-

Thicker Stainless Steel

-

Function:

-

Single Heating

-

Application Field:

-

Industrail

-

Capacity:

-

Steam Boiler 1t/h

-

Boiler Structure:

-

Horizontal Three Return Fire Tube Boiler

-

Rated steam temperature:

-

170/185 Degree

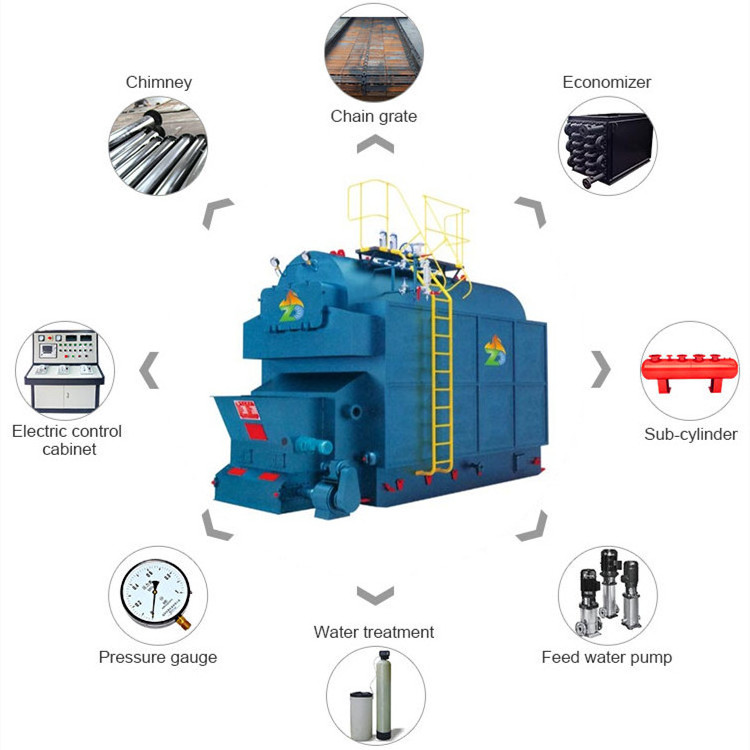

Henan Province Zhongde 20 tons Wood Pellet Biomass Fired Steam Boiler

DZL Coal Biomass steam(Hot Water) Boiler is energy saving and compact structure, the pressure raise up quickly. DZL series Biomass Hot Water Boiler is single drum horizontal type shell boiler, the combustion equipment is chain grate , has the advantages of feed mechanically and strong adaptability of different fuels. The fuel could be wood chips, rice hull, bagasse, straw, peanut shell, mustard stalk, cotton stalk, coconut shell, and waste cloth, etc. Biomass particle diameter should be 6-10 mm, length should be 25-50mm, and water content should be less than 15%. The source of solid biomass fired hot water boiler fuel is widespread, it is renewable green energy with the advantages of low cost, environmental friendly (sulfur content<0.06%, and zero CO2 emission), energy saving, and high combustion efficiency (>90%).

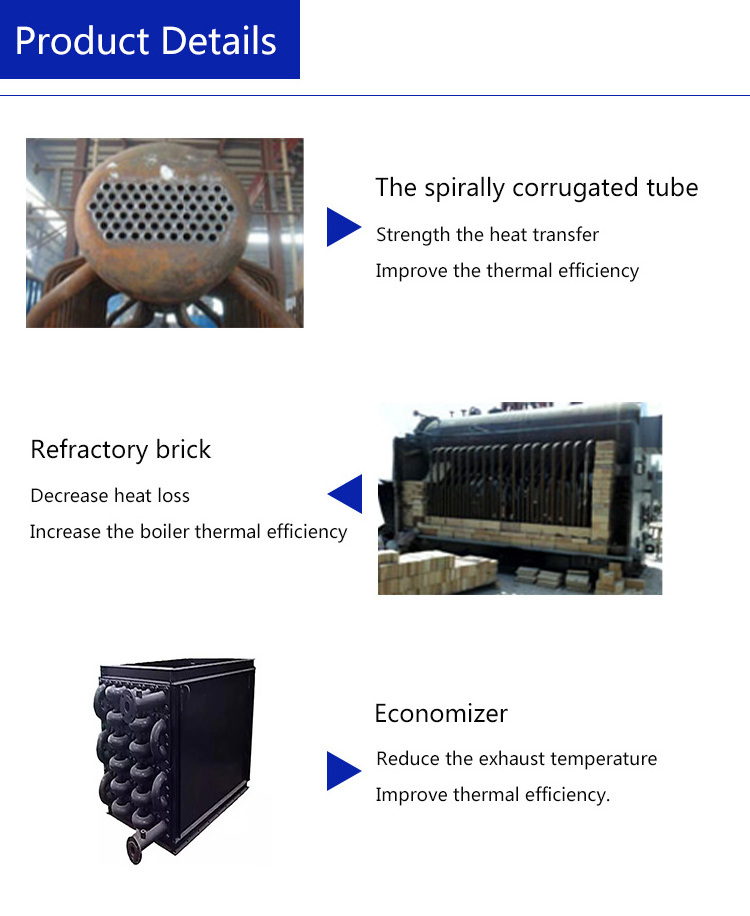

Product Details

Product specification

|

Boiler model

|

DZL1-0.7-T、DZL1-1.0-T、DZL1-1.25-T

|

DZL2-0.7-T、DZL2-1.0-T、DZL2-1.25-T

|

DZL4-1.25-T、DZL4-1.6-T

|

DZL6-1.25-T、DZL6-1.6-T

|

DZL8-1.25-T、DZL8-1.6-T

|

DZL10-1.25-T、DZL10-1.6-T(Up and down assembly)

|

|

Rated evaporation(t/h)

|

1

|

2

|

4

|

6

|

8

|

10

|

|

Rated steam pressure(MPa)

|

0.7/1.0/1.25

|

0.7/1.0/1.25

|

1.25/1.6

|

1.25/1.6

|

1.25/1.6

|

1.25/1.6

|

|

Rated steam temperature(℃)

|

170/184/194

|

170/184/194

|

194/204

|

194/204

|

194/204

|

194/204

|

|

Maximum shipping weight(t)

|

17

|

23

|

25

|

35

|

45

|

33(Upper part)28(Lower part)

|

|

Length×width×height(mm)

|

5.1×2.2×3

|

5.5×2.3×3.3

|

6.6×2.6×3.6

|

8.2×2.9×3.8

|

8.1×3.1×3.8

|

7.7×3.2×3.6(Upper part)8.6×3.0×2.6(Lower part)

|

Application

DZL steam boiler has high heating temperature, low working pressure, energy saving, and can be widely used in various industrial heating processes. Such as petrochemical industry, synthetic fiber industry, textile printing and dyeing, plastic rubber, paper industry, wood industry, building materials, machinery industry, food industry, electrical equipment, coking industry, metal and foundry industry, detergent industry, fat and coating industry, carbon Su industry.

Boiler case

Packing and shipping

Selling Units:Single item

Single package size: Depends on the capacity

Single gross weight:Depends on the capacity

Package Type:customized

Our survice

Pre-sale service:

1.Provide the most suitable and cost-effective boiler solution according to different requirements of various industry. 2.Provide drawings for building your boiler room,such as foundation drawing, layout drawing, boiler room layout, etc.

On-sale service:

24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product. We send pictures and videos to let customers know the production schedule.

After-sales service:

1.provide full range of original spare parts.

2.Provide engineers abroad installation and commissioning service.

3.Held online or site training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.

1.Provide the most suitable and cost-effective boiler solution according to different requirements of various industry. 2.Provide drawings for building your boiler room,such as foundation drawing, layout drawing, boiler room layout, etc.

On-sale service:

24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product. We send pictures and videos to let customers know the production schedule.

After-sales service:

1.provide full range of original spare parts.

2.Provide engineers abroad installation and commissioning service.

3.Held online or site training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.

Certifications

CE

CE

Boiler Manufacturing License

ISO9001

ISO14001

ISO45001

Hot Searches