Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

machine name:

-

induction brazing welding machine/induction heating equipment

-

power:

-

40kw

-

cooling method:

-

water cooling

-

output frequency:

-

10-40kHZ

-

voltage:

-

380V-420V

-

phase:

-

3 phase

-

frequency:

-

50/60HZ

-

rated input current:

-

60A

-

suitable metal:

-

copper, iron, steel, brass, aluminum, etc

-

application:

-

metal heat treatment:brazing, hardening, annealing, welding, etc

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Canroon

-

Weight (KG):

-

60

-

machine name:

-

induction brazing welding machine/induction heating equipment

-

power:

-

40kw

-

cooling method:

-

water cooling

-

output frequency:

-

10-40kHZ

-

voltage:

-

380V-420V

-

phase:

-

3 phase

-

frequency:

-

50/60HZ

-

rated input current:

-

60A

-

suitable metal:

-

copper, iron, steel, brass, aluminum, etc

-

application:

-

metal heat treatment:brazing, hardening, annealing, welding, etc

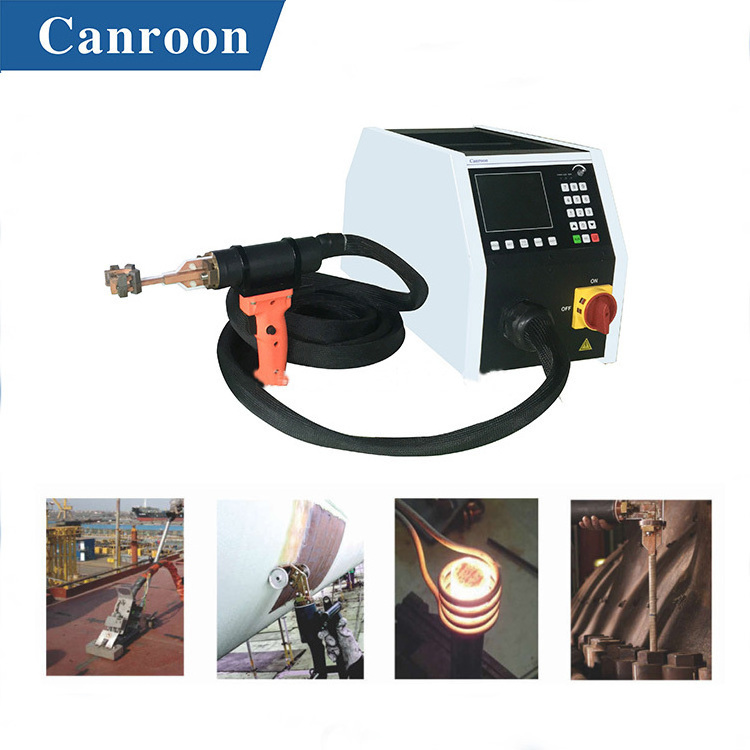

Canroon induction brazing welding machine/induction heating equipment

Contact: Sandy Liu

Mobile/Whatsapp/Wechat:0086-13715137235

Parameters of Canroon high frequency induction brazing welding machine induction heating equipment for metal heat treatment:

|

model |

Rated input voltage & frequency |

Rated input power |

Rated input current |

Output frequency |

Cooling water pressure / flow rate |

Dimension |

|

CR2100-010B-14TW1 |

3-phase

|

10KVA |

15A |

10~40KHZ |

4~6 bar ≥12L/min |

L: 581.5mm W: 283mm H: 334mm |

|

CR2100-015B-14TW1 |

15KVA |

22A |

||||

|

CR2100-020B-14TW1 |

20KVA |

30A |

||||

|

CR2100-025B-14TW1 |

25KVA |

37A |

4~6 bar ≥19L/min |

|||

|

CR2100-030B-14TW1 |

30KVA |

45A |

||||

|

CR2100-035B-14TW1 |

35KVA |

53A |

||||

|

CR2100-040B-14TW1 |

40KVA |

60A |

||||

|

CR2100-050B-14TW1 |

50KVA |

75A |

Picture of Canroon high frequency induction brazing welding machine induction heating equipment for metal heat treatment:

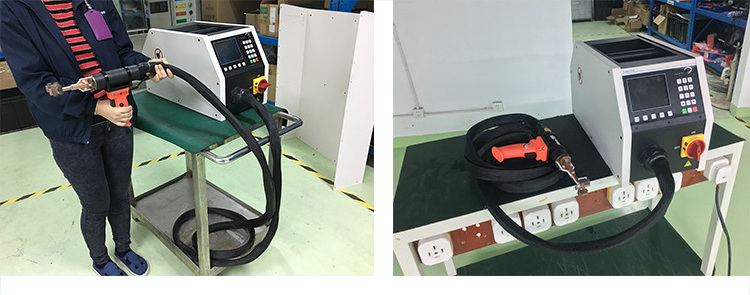

small in size, light in weight, portable, handheld, HHT,detachable inductor, modular design, digital control

Applications of high frequency induction brazing welding machine induction heating equipment for metal heat treatment:

Induction brazing of short circuit ring,

Induction brazing of copper wires on motor stator,

Induction brazing of rotor bar,

Induction brazing of rotor coil,

Induction brazing of heat exchanger,

etc

Induction Brazing of brass with Ag-Cu alloy as welding solder to make slip ring in motor for wide applications.

Induction brazing for copper plate:

HHT(hand held transformer) is easy to operate, and can be integrated with Robot Arm for automotion production, two buttons to control the machine working:

Inductors are important part of induction heater, it is precisely designed, manufactured

by good quality material, and tested many times before outgoing, it is detachable, and can be customized accoridng to your workpiece:

Advantages:

· High Temp. & Fast Heating

Able to reach >1000 ℃ within seconds.

· Easy Operation

CR2100 can be easily start&stop manually, and scan on workpieces surface to do local heating. It can also be integrated into robot arm to serve automatic line.

· Accurate Control

The interface offers two basic control modes to choose including temperature control and power control . Thus brings the benefit of wide applicability and precise control of heating process.

· Fault Record

Fault codes will display and be recorded for reference, and system will respond with protection action like shutdown once fault occurs such as open-loop output or short out.

· Easy Maintenance

Due to modular design , the maintenance will be easy and low-cost.

· Self-Diagnosis

Once fault occurs, CR2100 will act with display of fault code , which was detailed explained in the manual book.

· Customized Inductor

Canroon provided high-standard customized inductor to CR2100 induction generator, to help you deal with workpieces of different shap&size.

All of our induction heating equipment is carefully packed in wooden case for safe delivery, by sea, by air according to your need.

1. keep the quality first and make more products benefit to our customers' need

2.about our Online/Sale service

1)super and solid quality

2)Fast and punctual delivery

3)Standard export package or as customers’ need.

3.After-sale service

1)Assistance to your project

2)Repairing and maintenance if any problem occur in the warranty.

3)Installation and clerks training

4)Spare and wearing parts for free or with big discount

5)Any feedback of machines can be told to us, and we will try our best to support you.

4.Other cooperation service

1)Technology knowledge share

2)Factory building advising

3)Business expansion advising