- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

High Speed

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Hualong

-

Voltage:

-

380V/50Hz

-

Dimension(L*W*H):

-

796x222x226 cm

-

Weight:

-

15000 kg

Quick Details

-

Type:

-

Stone Polishing Machine

-

Power:

-

7.5KW

-

Cutting thickness (max):

-

10-60 mm

-

Production Capacity:

-

High Speed

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Hualong

-

Voltage:

-

380V/50Hz

-

Dimension(L*W*H):

-

796x222x226 cm

-

Weight:

-

15000 kg

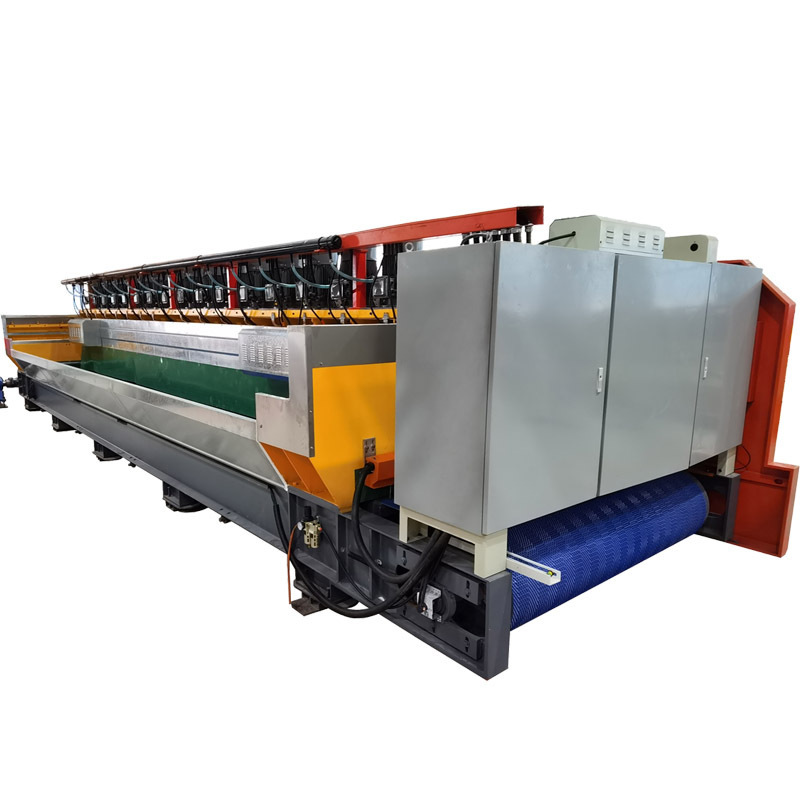

Automatic Continuous Stone Polishing Machine

HLMJX-16W

, an updated automatic stone finishing machine mounted with 16 polishing heads, is popular in the market for continous honing and polishing marble slabs, especially efficient for mass production. Matched with different type of grinder heads, an unmatched finish to slabs of granite, quartz or other natural stone or artificial stone is availabe to obtained too.

|

Technical Data

|

|

|

|

|||

|

Model No.

|

|

HLMJX-16W

|

HLMJX-20W

|

|||

|

Number of grinding head

|

pc

|

16

|

20

|

|||

|

Power of spindle motor

|

kw

|

15

|

15

|

|||

|

Gross power

|

kw

|

251

|

311

|

|||

|

Useful working width

|

mm

|

300-2100

|

300-2100

|

|||

|

Useful working thickness

|

mm

|

10-50

|

10-50

|

|||

|

Speed of belt advance

|

mm/min

|

0-3500

|

0-3500

|

|||

|

Water consumption

|

m

3

/min

|

25

|

30

|

|||

|

Gross weight

|

kg

|

28000

|

32000

|

|||

|

Dimensions ( L x W x H )

|

mm

|

11800x3090x2350

|

14000x3090x2350

|

|||

Main Features:

1) Using PLC electrical system and LCD screen menu offer intelligent control.

2) Processing width and working pressure of grinding heads can be adjusted freely .

3) Sensor at the entrance to scan the shape of the slabs in sequence and transmit the signal to controlling unit for precise

working

4) Adopting central automatic lubrication system, having all moving parts and bearings to get a good lubricating effect and longer life.

5) Conveyor self-cleaning and stone chip removing system

2) Processing width and working pressure of grinding heads can be adjusted freely .

3) Sensor at the entrance to scan the shape of the slabs in sequence and transmit the signal to controlling unit for precise

working

4) Adopting central automatic lubrication system, having all moving parts and bearings to get a good lubricating effect and longer life.

5) Conveyor self-cleaning and stone chip removing system

Hot Searches