- Product Details

- {{item.text}}

Quick Details

-

model:

-

as per client's requirement

-

heating way:

-

electricity/ steam boiler

-

function:

-

make the wood drying

-

Name:

-

autoclave for wood drying

-

heating medium:

-

steam

-

design pressure:

-

1.6Mpa

-

Working Principle:

-

high frequency heating and vacuum heating

-

Advantage:

-

shorten the drying time

Quick Details

-

Place of Origin:

-

Shandong, China

-

control system:

-

automatic or semi-automatic

-

material:

-

ss304 or Q345R

-

model:

-

as per client's requirement

-

heating way:

-

electricity/ steam boiler

-

function:

-

make the wood drying

-

Name:

-

autoclave for wood drying

-

heating medium:

-

steam

-

design pressure:

-

1.6Mpa

-

Working Principle:

-

high frequency heating and vacuum heating

-

Advantage:

-

shorten the drying time

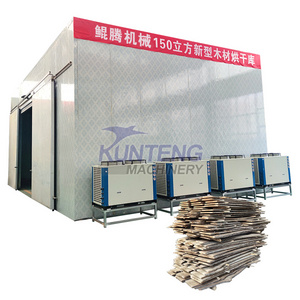

Industrial Autoclave Chamber For Wood Drying Machine

Autoclave for wood drying

Equipment features

- 1) Wood treatment equipment apply to be preservation, termite proof and to prevent fungal. Especially landscape floor, outdoor wood platform and wood plank road and other preservative wood pergola.

- 2) This treatment equipment have special craft for wood, such as: vacuum pressure method, fullcell method, high low frequency pressure as so on. Especially vacuum pressure method. The preservative level can get C4

- 3)You can use CCA and ACQ two kinds of preservative match our wood preservation equipment.

- 4) PLC is a new intelligent control wood preservative system, which make the wood preservation equipment to be easy, and to be safety, to be reliable.Meanwhile, Even if the wood don't be push out,this can accurately calculate if the preservative is permeated in the wood.

- About the material, we choose the best material to guarantee the quality of the boiler and to prolong the life time.

client from India

Working steps

|

1. Initial vacuum:vacuum first before adding the antiseptic,in order to draw out the air in the wood so that the antiseptic steeping the wood thoroughly.Generally the vacuum degree is 79.8-90kpa, steeping time own to the different products(generally 15-60 minutes),when the tank become vacuum tank,part of air in the wood is draw out, then the antiseptic can go into the wood more fluently.

|

|

2.Add the antiseptic:in the case of vacuum,adding the antiseptic by valve,to make sure the air stay inside of the wood.

|

|

3.Increase pressure:relief the vacuum when the tank is filled with antiseptic,then increase the pressure slowly to 1.0-1.4Mpa and stay at this press until prescribed antiseptic are totally injected into the wood.

|

|

4.Pressure relief,removal of preservatives:when the prescribed antiseptic are totally absorbed,then discharge the pressure inside the tank,there may be a certain degree of recoil at this moment(5-15%)

|

|

5.Final vacuum:when the antiseptic are discharged in the tank,then vacuumized the tank,in order to extract the excess antiseptic out of the cell and surface of the wood to reduce dropping liquid when take out the wood.

|

|

6.Open the door and take out the wood when the atmosphere restored |

Autoclave for wood drying photos

Site Planning and Proposal Design

to provide targeted, energy-efficiency technology solution according to

the request of client, and to plan the supporting facilities of sterilization equipment in details based on customer’s site.

Turnkey Service

From technical scheme design to project implementation and commissioning, sterilization equipment specialists provide technical services in the whole process to save your worry and effort, to experience one-stop engineering.

Periodic testing and maintenance of key equipment

Reduce equipment failure and abnormal shutdown and improve reliabiligy, professional service for emergency fault protects equipment and prolong life to reduce overall operating costs