- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

GTS

-

Power:

-

3-30KW

-

Weight (KG):

-

27000 kg

-

After-sale Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Municipal Solid hazardous Waste Incineration To Energy Power Plant

-

Max Feed Size:

-

400mm

-

Discharge Size:

-

0-100mm

-

Screen Diameter:

-

1000-2500mm

-

Screen Length:

-

1500-15000mm

-

Installation:

-

Engineer Guidence

-

Capacity:

-

20-300t/hour

-

Motor:

-

Chinese famous brand or as required

-

Material:

-

Steel, cast iron

Quick Details

-

Production Capacity:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongzhi

-

Model Number:

-

GTS

-

Power:

-

3-30KW

-

Weight (KG):

-

27000 kg

-

After-sale Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Municipal Solid hazardous Waste Incineration To Energy Power Plant

-

Max Feed Size:

-

400mm

-

Discharge Size:

-

0-100mm

-

Screen Diameter:

-

1000-2500mm

-

Screen Length:

-

1500-15000mm

-

Installation:

-

Engineer Guidence

-

Capacity:

-

20-300t/hour

-

Motor:

-

Chinese famous brand or as required

-

Material:

-

Steel, cast iron

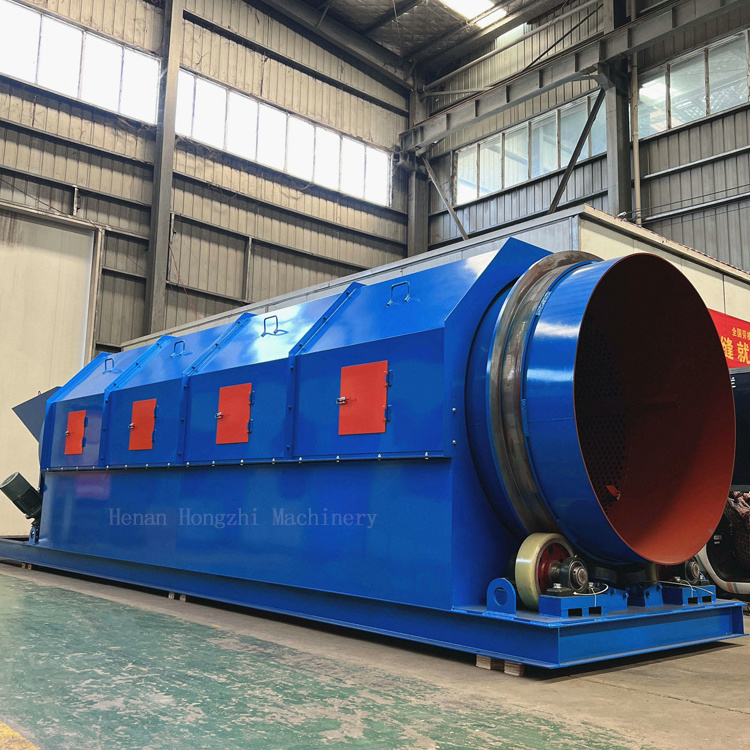

General Introduction of waste trommel screen

The GTS shaftless drum screen is a screening equipment developed by our company for environmental protection engineering technology, household waste treatment, aged waste treatment, decoration waste, comprehensive waste treatment and other industries. It has the advantages of simple structure, convenient operation, high screening efficiency,and is suitable for screening materials of various properties. According to the specific requirements of the screened materials,the screened materials are 30mm and 80mm respectively. This product has been highly praised by users.

Waste trommel screen structure and working principle

1. This machine mainly consists of mechanisms such as electric motor, reducer, support wheel, drum body, screen, frame, dust cover, etc

2. The electric motor drives the reducer, and then the friction wheel drives the screen drum mechanism

to rotate around its axis. When the material enters the screen drum device, the rotation of the screen drum

device causes the animal material to rotate to a certain height, and the material is thrown and falls due to gravity. After passing through the screen mesh, the material smaller than the screen mesh hole diameter (single or multi stage screen mesh) is discharged outside the screen drum, and the material larger than the screen mesh aperture is discharged through the end of the screen drum, thereby achieving the classification

of material size.

3. The sieve drum device is sealed by the body sealing cover to ensure that the equipment is in operation, effectively preventing dust from escaping and eliminating dust pollution.

Applications filed of waste trommel screen

Urban or Household waste: organic, inorganic, waste paper, plastic bags, fabrics, plastics, glass, metals, etc... Construction waste: muck, waste concrete, waste masonry and rubble, brick and tile fragments, waste mortar slurry, asphalt blocks, waste plastics, waste metal, waste bamboo and wood, industrial waste.All of these sorted waste can be recycled after reprocessing.

Waste trommel screen features

1. Adopting the principle of rolling conveying, the friction coefficient is small, the wear is light, and the sieve holes are not easily blocked.

2. The drum is supported by a roller assembly to support the operation of the large rolling ring. The roller is coated with polyurethane, which has high friction, low vibration, smooth operation, and low noise.

3. The drum body adopts an effective fully sealed structure, which does not raise dust,pollutes, and prevents exhaust gas leakage.

4. Safe and reliable operation, using a gearbox for variable speed transmission, with high transmission efficiency, low belt power, low energy consumption, and obvious energy-saving effect.

5. The sieve holes are arranged in a plum blossom array, which has a higher utilization rate and better screening effect than the matrix arrangement.

2. The drum is supported by a roller assembly to support the operation of the large rolling ring. The roller is coated with polyurethane, which has high friction, low vibration, smooth operation, and low noise.

3. The drum body adopts an effective fully sealed structure, which does not raise dust,pollutes, and prevents exhaust gas leakage.

4. Safe and reliable operation, using a gearbox for variable speed transmission, with high transmission efficiency, low belt power, low energy consumption, and obvious energy-saving effect.

5. The sieve holes are arranged in a plum blossom array, which has a higher utilization rate and better screening effect than the matrix arrangement.

Technical Parameters of waste trommel screen

|

Model

|

Drum size

(m)

|

inclination

(°)

|

Rotation speed

(r/min)

|

Screen size

(mm)

|

Max feeding size

(mm)

|

Capacity

( m³/h)

|

Power

(kw)

|

|

GTS820

|

Φ0.8×2

|

6-10

|

32

|

2-20

|

screen size x 2.5

|

7-30

|

3

|

|

GTS830

|

Φ0.8×3

|

6-10

|

32

|

2-20

|

screen size x 2.5

|

8-50

|

3

|

|

GTS1020

|

Φ1×2

|

6-10

|

25

|

2-20

|

screen size x 2.5

|

10-60

|

4

|

|

GTS1030

|

Φ1×3

|

6-10

|

25

|

2-20

|

screen size x 2.5

|

11-80

|

4

|

|

GTS1230

|

Φ1.2×2

|

6-10

|

20

|

2-20

|

screen size x 2.5

|

12-100

|

5.5

|

|

GTS1240

|

Φ1.2×4

|

6-10

|

20

|

2-20

|

screen size x 2.5

|

14-120

|

5.5

|

|

GTS1530

|

Φ1.5×3

|

6-10

|

17

|

2-20

|

screen size x 2.5

|

16-120

|

5.5

|

|

GTS1540

|

Φ1.5×4

|

6-10

|

17

|

2-20

|

screen size x 2.5

|

18-150

|

7.5

|

|

GTS1550

|

Φ1.5×5

|

6-10

|

17

|

2-20

|

screen size x 2.5

|

20-180

|

11

|

|

GTS1560

|

Φ1.5×6

|

6-10

|

17

|

2-20

|

screen size x 2.5

|

22-200

|

11

|

|

GTS1850

|

Φ1.8×5

|

6-10

|

14

|

2-20

|

screen size x 2.5

|

24-220

|

15

|

|

GTS1860

|

Φ1.8×6

|

6-10

|

14

|

2-20

|

screen size x 2.5

|

26-240

|

15

|

|

GTS2050

|

Φ2×5

|

6-10

|

12

|

2-20

|

screen size x 2.5

|

50-600

|

22

|

|

GTS2080

|

Φ2×8

|

6-10

|

12

|

2-20

|

screen size x 2.5

|

80-700

|

22

|

|

GTS2260

|

Φ2.2×6

|

6-10

|

10

|

2-20

|

screen size x 2.5

|

100-800

|

30

|

|

GTS2280

|

Φ2.2×8

|

6-10

|

10

|

2-20

|

screen size x 2.5

|

120-850

|

30

|

Shipping and package of

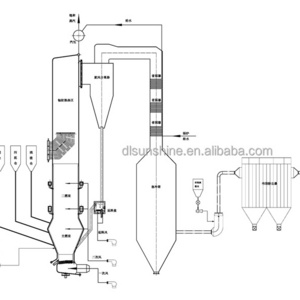

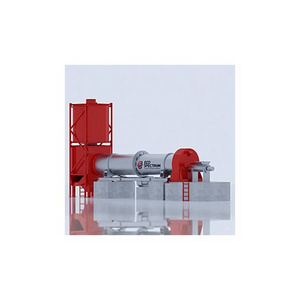

waste trommel screen

Henan Hongzhi machinery mainly focuses on design and manufacturing waste sorting machines. include trommel screen machine, air separator, magnetic separators, garbage bag breaking machine, waste shredder machine, manual sorting tables, waste baling machine,chain plate feeder, belt conveyor.etc. Henan Hongzhi machinery is a high-tech modern enterprise integrating scientific research and development, production and sales, engineering design, installation services. Our machine has passed CE certification. Our machines has already spread over the world. We can provide customers with one-stop service and solutions, complete equipment,on-site installation, and after-sales support.

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer in China, passed Alibaba field certification.

Q2: How long is the warranty period?

A2: Normally 12 months. Except for wearing parts.

Q3: What’s your delivery time??

A3: We will arrange for shipping in factory within 15 working days after receiving the advance payment.

A1: We are a professional manufacturer in China, passed Alibaba field certification.

Q2: How long is the warranty period?

A2: Normally 12 months. Except for wearing parts.

Q3: What’s your delivery time??

A3: We will arrange for shipping in factory within 15 working days after receiving the advance payment.

Hot Searches