- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

soap pressing machine

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

pressing molds

-

Name:

-

soap stamping machine

-

Type:

-

soap printing machine

-

Application:

-

black soap stamping machine

-

Usage:

-

automatic soap stamping machine

-

Function:

-

soap cutting stamping machine

-

Capacity:

-

pneumatic soap press machine

-

Air press:

-

stamping machine for soap

-

Related machine:

-

soap cutting machine

-

Keywords:

-

soap stamping machine price

-

Product name:

-

bar soap press

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yize

-

Weight (KG):

-

200

-

Machine Type:

-

soap pressing machine

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

pressing molds

-

Name:

-

soap stamping machine

-

Type:

-

soap printing machine

-

Application:

-

black soap stamping machine

-

Usage:

-

automatic soap stamping machine

-

Function:

-

soap cutting stamping machine

-

Capacity:

-

pneumatic soap press machine

-

Air press:

-

stamping machine for soap

-

Related machine:

-

soap cutting machine

-

Keywords:

-

soap stamping machine price

-

Product name:

-

bar soap press

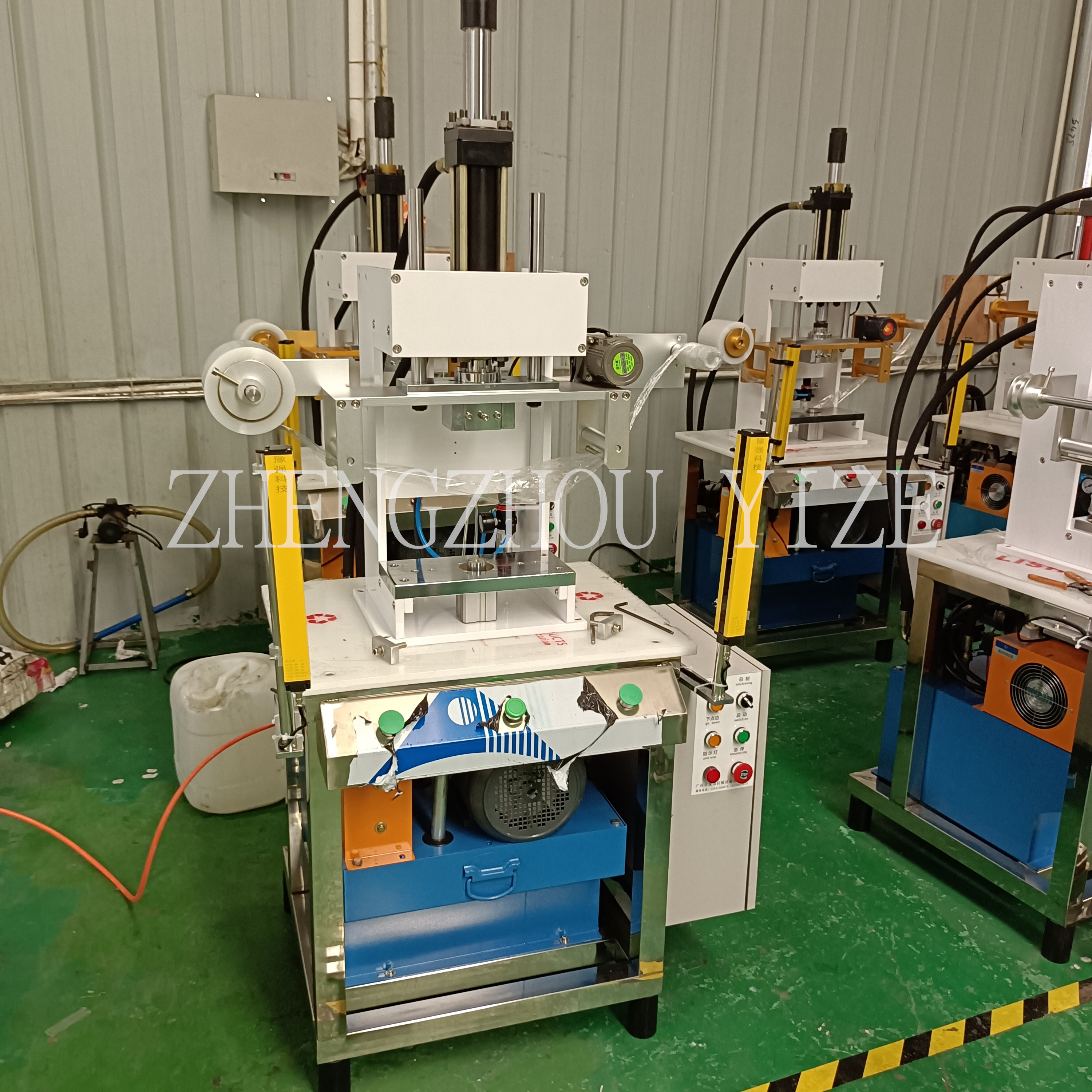

Automatic laundry soap press making machine manual toilet bar soap shape logo stamping stamper moulding machine:

Brief introduction:

This soap stamping machine has light curtain protection device, which is an effective protection device and safer than protective guard, and can protect operator from danger.

It is safe and easy to operate, save labor and improve production.This machine can print different size and shape of soap without changing mold.

The technical parameters of the soap stamping machine:

|

Model

|

YZCY-01

|

|

Power

|

2.2kw

|

|

Capacity

|

20-30pcs/min

|

|

Air press

|

4-6kg.cm3

|

|

Machine size

|

67*62.5*173cm

|

|

Weight

|

200kg

|

We have different types of soap stamping machine :

1.semi-automatic

2.Pneumatic and manual type

3.easy to operate

1.Semi-automatic soap stamping machine:

The user needs to start the machine, but the pressing process still requires manual intervention, such as changing the mold or manually moving the finished product.

2.Pneumatic

soap stamping machine

3. Manual soap stamping machine

Procedure of use:

1, Before installing the mold, firstly turn the restrictor screw on the upper part of the hydraulic cylinder clockwise to the bottom, then slowly turn counterclockwise for one and a half or two weeks, so that the central axis of the cylinder is slowly lowered, and the upper and lower switches can be jogged.

2, Then Install the upper and under cores in the die holder and tighten the chuck screws.