- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Raloyal

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

7500*2300*1800mm

-

Weight:

-

4000 kg

-

Marketing Type:

-

New Product 2023

-

Roll Loading:

-

1 Roll, 2 Rolls, 4 Rolls

-

Web Guide:

-

yes

-

Control System:

-

PLC+Touch Screen

Quick Details

-

Type:

-

sheeting machine

-

Production Capacity:

-

100 pcs/min

-

Max. workable width:

-

1100mm/ 1300mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Raloyal

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

7500*2300*1800mm

-

Weight:

-

4000 kg

-

Marketing Type:

-

New Product 2023

-

Roll Loading:

-

1 Roll, 2 Rolls, 4 Rolls

-

Web Guide:

-

yes

-

Control System:

-

PLC+Touch Screen

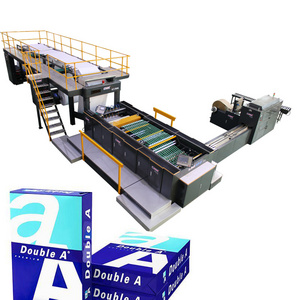

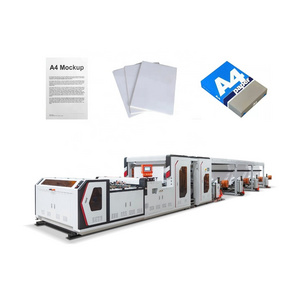

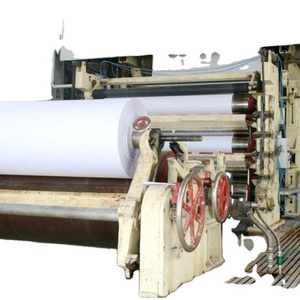

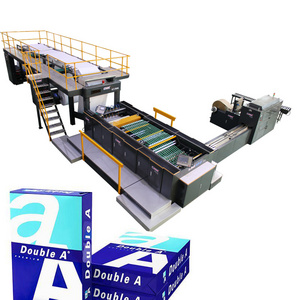

Products Description

Application

:

This machine is specialist for horizontal and vertical cutting paper rolling materials to A1,A2,A3,A4 size.

Advantage

:

* Adopts pneumatic automatic materials loadingsystem with much easy operation and convenience.

* Adopts down-up recurrent cutting with orderly finished products and without watercaltrop;meantime,it can be used for horizontal

cutting and vertical cutting at one time.

* It adopts servo motor for controlling constant-length cutting.

* It adopts PLCcontrol, contact screen operation.

* It adopts pneumatic, displacement sensor for controlling transmission system, with photoelectric, gas together, it has the

function of easy operation, high precision, good stability, low noise.

* This machine has the function of the frequencyconverter timing device, automatic counting, stop working by alarm, magnetic

powder tension control, can be vertically, adopt blower fan to get rid of waste.

* It has the functions of high-precision of cutting, high speed,etc . pneumatic structure combined with computer control be

adopted for transmission section, making it become much more steady operation.

* It has the function of automatic stacking which is in order . Photoelectric auto tracing subtense system.

* Adopts down-up recurrent cutting with orderly finished products and without watercaltrop;meantime,it can be used for horizontal

cutting and vertical cutting at one time.

* It adopts servo motor for controlling constant-length cutting.

* It adopts PLCcontrol, contact screen operation.

* It adopts pneumatic, displacement sensor for controlling transmission system, with photoelectric, gas together, it has the

function of easy operation, high precision, good stability, low noise.

* This machine has the function of the frequencyconverter timing device, automatic counting, stop working by alarm, magnetic

powder tension control, can be vertically, adopt blower fan to get rid of waste.

* It has the functions of high-precision of cutting, high speed,etc . pneumatic structure combined with computer control be

adopted for transmission section, making it become much more steady operation.

* It has the function of automatic stacking which is in order . Photoelectric auto tracing subtense system.

Technical Parameter

|

1

|

Machine Model

|

LY-C1100B

|

LY-C1300B

|

|

|

2

|

Unwinding Width

|

1100mm

|

1300mm

|

|

|

3

|

Unwinding Diameter

|

Φ1400mm

|

|

|

|

4

|

Weight of Cutting Paper

|

40-500gsm

|

|

|

|

5

|

Cutting Length

|

20-1000mm

|

|

|

|

6

|

Cutting Speed

|

10-150times/min

|

|

|

|

7

|

Machine Capacity

|

1 roll: 1.5reams/min

|

1.8reams/min

|

|

|

|

|

2 rolls: 3reams/min

|

3.6reams/min

|

|

|

|

|

4 rolls: 6reams/min

|

7.2reams/min

|

|

Details Images

Related Products

Why Choose Us

1. Quality Control

Incoming Quality Control

Our quality team will inspect the incoming parts before storage by sampling.

Process Quality Control

Our quality team will pick the first pcs of each kind part to inspect before assembly and also inspect randomly on site.

Outgoing Quality Control

Our quality team will inspect the machine’s appearance, features and characteristic etc. before delivery to meet and exceed client’s expectation.

2. Packing & Delivery

3. Certifications

4. Our Service

Inquiry and consulting support.

Sample material testing support.

Lead the customer to visit our factory if required.

12 months guarantee, life-long time technic maintenance and support.

Online Guidance support. Spare parts supports.

24 Hours * 7 days service online.

Hot Searches