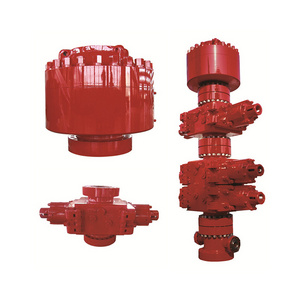

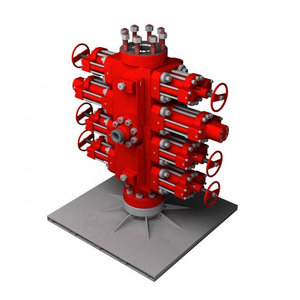

•Rubber core store glue big quantity , small friction resistance, whens witch pressure sealing ability.

•Using hemis pherical head, no stress concentration phenomenon when under pressure, casing stress evenly, easy to tear open outfit.

•Piston stroke is short, low height, and set the wear ring.

•High sulfate-resistant blowout preventer internal all parts contact well liquid surfacing high nickel base alloy, can achieve the highest levels of resistance to effect such as H2S and CO2.

•Steam circulating lines can be designed and machined to adapt to low temperature environment.