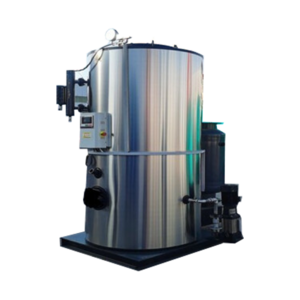

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Weight

-

Certification:

-

ASME,ISO,SGS

-

steam boiler safe:

-

yes

-

operation:

-

auto

-

processing type:

-

water

-

manufacturing capacity:

-

factory

-

type of fyel:

-

coal,biomass pellet,wood chips,sawdust,rice husk,etc

-

rated evaporation:

-

0.5-20t/h

-

rated working pressure:

-

0.7-1.25MPa

-

steam temp:

-

170-193dgr

-

steam boiler warrantly:

-

one year

-

type of boiler:

-

industrial steam boiler

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WILFORD, steam boiler

-

Dimension(L*W*H):

-

Depends

-

Weight:

-

Weight

-

Certification:

-

ASME,ISO,SGS

-

steam boiler safe:

-

yes

-

operation:

-

auto

-

processing type:

-

water

-

manufacturing capacity:

-

factory

-

type of fyel:

-

coal,biomass pellet,wood chips,sawdust,rice husk,etc

-

rated evaporation:

-

0.5-20t/h

-

rated working pressure:

-

0.7-1.25MPa

-

steam temp:

-

170-193dgr

-

steam boiler warrantly:

-

one year

-

type of boiler:

-

industrial steam boiler

Product Description

1.The boiler adopts the latest research results,such as:arched tube plate,screw thread smoke tube,hot water boiler backwater ejection technology,solves the pot type boiler tube plate crack at the lower part of the drum,drum kits,water wall tube broken ,low thermal efficiency,low output,poor adaptability of coal.

2.Combustion:fuel from coal scuttle fall in front of the stove grate,during operation ,after coal preheating and dry distillation,ignition,combustion,the slag drop into the slag bucket,then been removed out furnace by by slagging machine at any time.Furnace arch uses herringbone arch,improving the conditions of ignition.Flue gas forms vortex between the throat of the front,rear arch mixed with air.After combustion ,flue gas enters the two wings flue,through the front smoke box into the thread smoke tube,then go through cast iron economizer(hot water boiler no need )dust collextor,finally discharged by lead fan to chimney.

3.Boiler water circulation progresses on natural circulation and ejection. The radiation heating surface is left and right side cold water wall .The two wings of boiler furnace are main convection heating surface.The thread smoke tube in boiler furnace are convection heating surface.The boiler furance is seperated by fold smoke wall-firebox and reburning chamber .Boiler main body is covered by three-dimensional shape plate shell

Technical Parameter

| Type | DZL0.7 | DZL1.4 | DZL2.8 | DZL4.2 | DZL5.6 | DZL7 | ||

| Project | Unit | |||||||

| Rated thermal power | MW |

0.7 (600000 kcal/h) |

1.4 (1.2 million kcal/h) |

2.8 (2.4 million kcal/h) |

4.2 (3.6 million kcal/h) |

5.6 (4.8 million kcal/h) |

7 (6million kcal/h) |

|

|

The rated steam pressure |

Mpa | 0.7,1.0,1.25,1.6 | ||||||

|

The water temperature/return water temperature |

℃ | 95/70,115/70,130/70 | ||||||

| Avaible fuel | (AⅡ) | |||||||

|

Design the thermal efficiency |

% | 80.2 | 80.8 | 80 | 82.3 | 80.3 | 80.8 | |

| The fuel consumption | Kg/h | 129 | 351.3 | 693 | 1041.9 | 1089 | 1707.8 | |

|

The transport dimension |

5200*2100 *3000 |

5525*2440* 3400 |

6081*2450 *3500 |

8000*2700 *3550 |

8000*2900 *3550 |

8980*3200 *3600 |

||

| Boiler installation structure | The fast The assembly | |||||||

| Please contact us for more product information. | contact us >> |