- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Lianxin

-

Voltage:

-

CUSTOMIZED

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

95

-

Weight:

-

10T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Usage:

-

wood plastic sheet making

-

Automatic Grade:

-

Automatic

-

Power:

-

120KW

-

Output (kg/h):

-

150 - 240 kg/h

-

Certification:

-

CE ISO9001:2008

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:1

-

Screw Speed (rpm):

-

89 rpm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Lianxin

-

Voltage:

-

CUSTOMIZED

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

95

-

Weight:

-

10T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Usage:

-

wood plastic sheet making

-

Automatic Grade:

-

Automatic

-

Power:

-

120KW

-

Output (kg/h):

-

150 - 240 kg/h

-

Certification:

-

CE ISO9001:2008

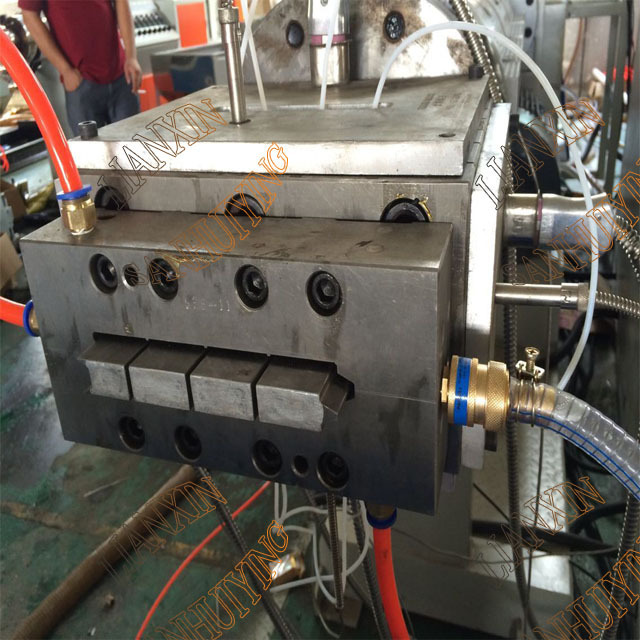

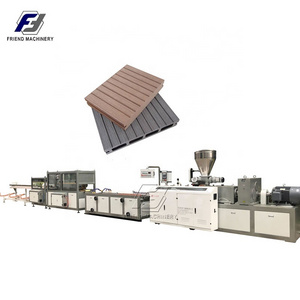

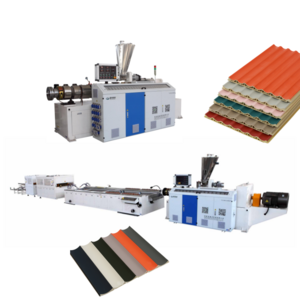

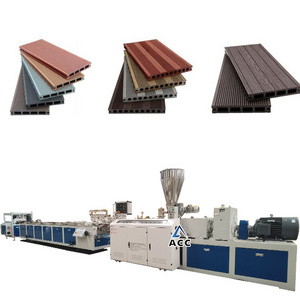

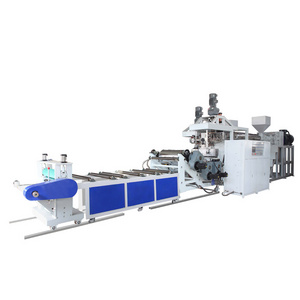

Wood plastic profile extrusion machine

Wood plastic extrusion profile machine is mainly used for producing PVC+wood flour, shirting

Board, door border line, door pocket line, louvre blade, picture frame, edge sheet of

Furniture, doorcase, door pocket, upright post, stair railing, etc. Wood plastic extrusion profile machine adopting the special wood-plastic technology and formula from our company, can design different product

According to different board section and purpose. With different mould and double

Screw extruder and Single Screw Extruders special for woodplastic, can produce different wood

Plastic board by vacuum forming machine, tractor, cutting machine, and upengder, etc.

Special technology has been adopted for tractor, so Wood plastic extrusion profile machine has many advantages, such

As run steadily, high reliability, stronger traction, . Vacuum forming device adopts

Special oversize vortex cooling system in order to satisfy the actual demand of

Producing wide board with convenience for forming, cutting device keeps pace with

The board pulling speed with rational design, stable operation, automatic scale cutting,

And equipped with dust reclaimer.

Specification:

1. The material is PVC+ wood powder

2. With the special woo-plastic technology and formula of our company.

3. Different mould can produce different proudcts

4. Stable working and reliable.

Main technology parameter of extruder

|

Model |

SJSZ45/100 |

SJSZ51/105 |

SJSZ55/120 |

SJSZ65/132 |

SJSZ80/156 |

SJSZ92/188 |

|

Power of drive mo tor (kw) |

15 |

18.5 |

22 |

37 |

55 |

110 |

|

Screw diameter (mm) |

Ø45/Ø100 |

Ø51/Ø105 |

Ø55/120 |

Ø65/Ø132 |

Ø80/Ø156 |

Ø92/188 |

|

No.of screw |

2 |

2 |

2 |

2 |

2 |

2 |

|

Rotational speed |

36 |

36 |

36 |

36 |

36 |

36 |

|

Nm torsional moment of screw |

3148 |

6000 |

7000 |

10000 |

14000 |

32000 |

|

Capacity PVC powder (kg/h) |

70 |

100 |

150 |

250 |

400 |

750 |

|

Central height(mm) |

1000 |

1000 |

1000 |

100 |

1000 |

1100 |