- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YUSHI

-

Model Number:

-

YUT-2820

-

Product name:

-

Digital Ultrasonic Flaw Leak Detector

-

Operating Mode:

-

Pulse echo, double crystal

-

Application:

-

industrial detection

-

Curve:

-

DAC, AVG

-

Power supply:

-

AC 220V,DC 12V

-

Working Frequency:

-

(0.5-15)MHz

-

Definition:

-

≥32dB

-

Vertical Linearity Error:

-

≤3%

-

Horizontal Linearity Error:

-

≤0.3%

-

Battery Working Time:

-

9 hours

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

YUSHI

-

Model Number:

-

YUT-2820

-

Product name:

-

Digital Ultrasonic Flaw Leak Detector

-

Operating Mode:

-

Pulse echo, double crystal

-

Application:

-

industrial detection

-

Curve:

-

DAC, AVG

-

Power supply:

-

AC 220V,DC 12V

-

Working Frequency:

-

(0.5-15)MHz

-

Definition:

-

≥32dB

-

Vertical Linearity Error:

-

≤3%

-

Horizontal Linearity Error:

-

≤0.3%

-

Battery Working Time:

-

9 hours

digital portable ultrasonic flaw detector YUT-2820 ultrasonic flaw detector transducer welding inspection equipment

♥

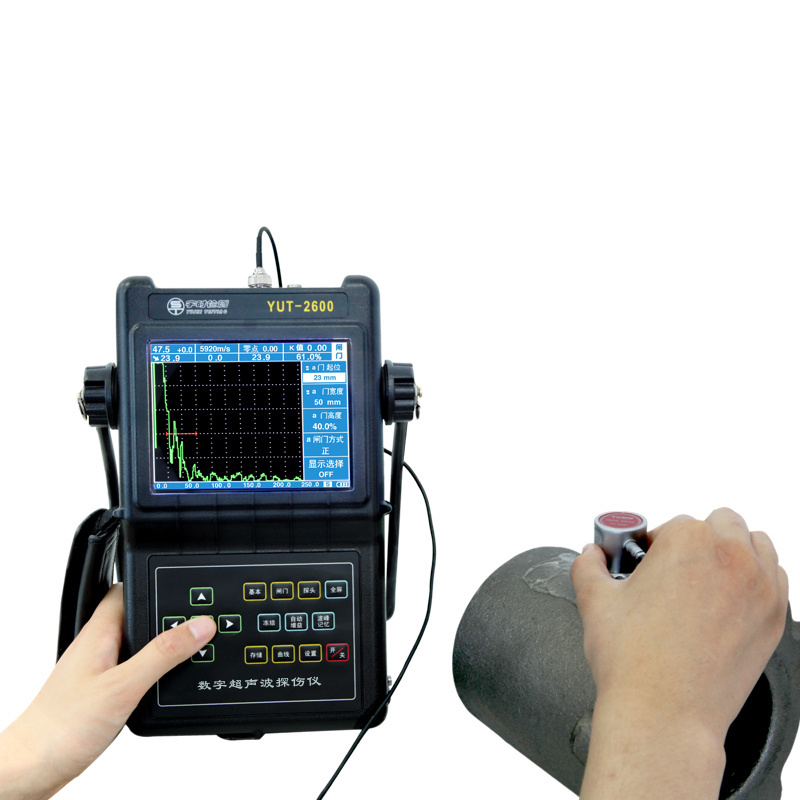

The firm and durable YUT-2820 is designed for the severe environment.

♥ Specifications of YUT-2820 Ultrasonic Flaw Detector

| Full Screen Display Function | The echo display area covers the entire screen |

| Bulk Storage | Up to 1000 data sets can be stored, including waveforms, curves and parameters, etc |

| Measuring Point | Peak Mode or Front Mode |

| Echo-echo Method |

No need of zero calibration, the net thickness of the base material can be directly measured through the coating |

| Wave Crest Memory |

Real time envelopes show the highest wave of the flaws and record the maximum value of the flaws, it is helpful to exact positioning and fast testing of the flaws |

| Automatic Gain | Automatically adjust the gain to the preset amplitude height |

| Alarming Function | Afferent echo/echo loss alarming |

| Solid Waveform | The solid waveform can enchancing the waveform visual contrast so the omission will hardly happen during the fast testing |

| Real-time Clock | Automatically record the date and time of the stored waveforms |

| Display Freezing |

Catching the waveform and sound path data at any moment |

| Flaw Positioning | Real-time displaying the sound path S, horizontal height X, depth Y, and wave height H |

| Flaw Quantify | Real time display the dB difference value and sl quantitative value |

| Digital Inhibition | 0-80%, increasing by 1%, not affecting the linearity and gain |

|

Independent M easurement Shutters |

2 independent measurement gates, monitoring the echo amplitude and the sound path distance |

|

DAC/AVG Curve Functions |

Perfect DAC and AVG curve functions enable the curves to change along with the changes of the gain, sound path, and displacement |

|

Distance Compensation |

When the resolving power in the near field is not influenced, only the remote signal will be compensated for its sensitivity so as to improve the testing range of the device significantly |

| Φ Value Calculation | This function is used for calculating the flaw quivalent |

|

Transverse Wave Testing Method |

When using transverse wave to detect flaws, the depths of the second and third waves are automatically calculated according to the slab thickness |

|

Pulse Generator with Changeable Width and Scope |

The voltage of the pulse generator can be changed between 50V to 400V continuously,The width of the pulse can be change d between 25ns to 1000ns continuously |

|

Damping |

Changed among 4 levels: 33/50/100/500Ω |

| Wave Signal Filter | Changed between 2 levels: 1-4MHz/0.5-15MHz |

| Repeating Frequency | Changed freely to avoid unreal signal |

|

Languages |

Chinese and English |

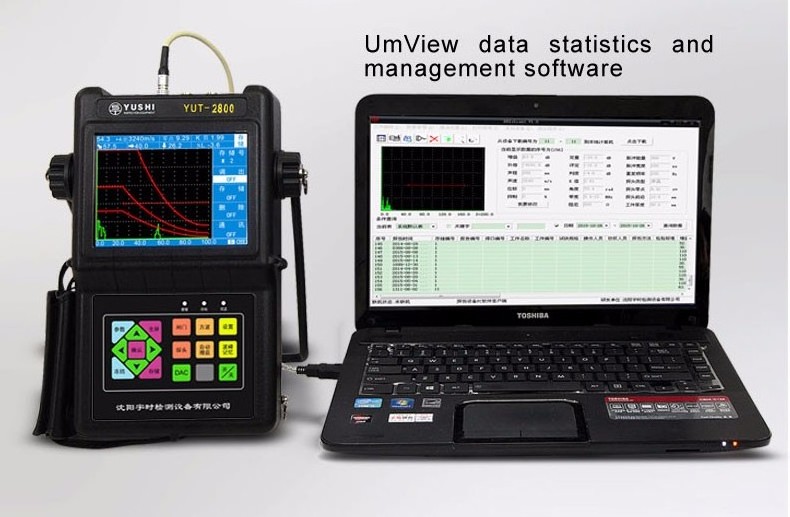

| Data Communication |

Communicating with the computer via RS232 interface to transfer the waveform and data |

♥ True color TFT LCD display, whose brightness is adjustable.

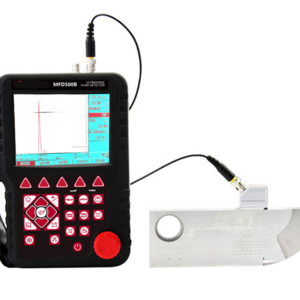

♥ The Actual Application of DAC Curve in detection

♥ With industry-leading probe production technology,We select the high performance of piezoelectric ceramic chips,regardless of the cost to build high quality.

♥ Demension and Weight of YUT-2820 Ultrasonic Flaw Detector

♥

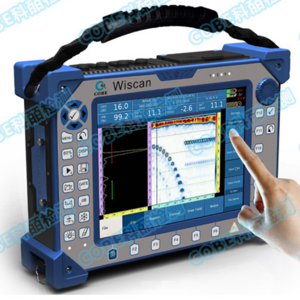

Main Comparison Between Different Models

| Model | YUT-2600 | YUT-2620 | YUT-2800 | YUT-2820 |

|

True Color TFT LCD

|

√ | √ | √ | √ |

|

DAC Curve

|

√ | √ | √ | √ |

|

AVG Curve

|

χ | √ | χ | √ |

|

Φ Value Calculation

|

χ | √ | χ | √ |

|

Distance Compensation

|

χ | √ | χ | √ |

|

Changeable Squared Ultrasonic Pulse

|

χ | χ | √ | √ |

| Wide/Narrow Band Filters | χ | χ | √ | √ |

| Four Impedance Matching | χ | χ | √ | √ |

| Data Logger | √ | √ | √ | √ |

| UtView Software | √ | √ | √ | √ |

♥ Technical Parameters of YUT-2820 Ultrasonic Flaw Detector

| Item | Index | Item | Index |

| Working Frequency | (0.5-15)MHz | Sensitivity Excess | ≥60dB (deep Φ2 Flat-bottom hole) |

| Material Sound Vecocity | (1000-9999) m/s | Definition | ≥32dB |

| Operation Mode | Pulse echo, double crystal | Dynamic Range | ≥30dB |

| Pulse Shift | (0-1000)mm | Average Noise Level | ≤10% |

| Probe Zero | (0-199.99)us | Battery Working Time | 9 hours |

| Gain Control | (0-110)dB,(0.1,1-2,6)dB stepping | Power Supply | 12V DC ,220V AC |

| Vertical Linearity Error | ≤3% | Dimensions | 270mm x190mm x 60mm |

|

Horizontal Linearity

|

≤0.3% | Weight | 2kg(including batteries) |

♥

Field Measurements

of YUT-2820 Ultrasonic Flaw Detector

♥ Specially Used For Training Institutions

♥

Standard Configuration

of YUT-2820 Ultrasonic Flaw Detector

| NO. | Item | Quantity |

| 1 | Ultrasonic Flaw Detector | 1 |

| 2 | Lithium battery | 1 |

| 3 | Charger (with power line) | 1 |

| 4 | Communication Cable | 1 |

| 5 | Straight Beam Probe | 1 |

| 6 | Angle Probe | 1 |

| 7 | Probe Cable (BNC-BNC) | 2 |

| 8 | Instrument Case | 1 |

| 9 | Instrument Case Belt | 1 |

| 10 | User Manual, Packing List, Warranty Card | 1 |

| 11 | Data Communication Software (electronic-directions inside) | 1 |

| 12 | Demo Disc | 1 |

♥ About Us

♥ FAQ

Q:What’s your after-sales service and warranty?

A: We promise to bear the following responsibility when defective product is found:

1.12 months warranty from the first day of receiving goods;

2. Replacements would be sent with goods of your next order;

3. Refund for defective products if customers require.

Q:Do you accept OEM orders?

A: Yes, we provide OEM services to worldwide customers.

Q:What’s the MOQ?

A: MOQ is 10pcs for standardized products; for customized products, MOQ should be negotiated in advance. There is no MOQ for sample orders.

Q:How long is the lead time?

A: The lead time for single order is 1-3 days, for bulk orders is 3-10 days.

Q:How to place orders?

A: 1. Email us the model and quantity, consignee information, shipping way and payment terms;

2. Proforma Invoice made and sent to you;

3. Complete Payment after confirming the PI;

4. Confirm Payment and arrange production.