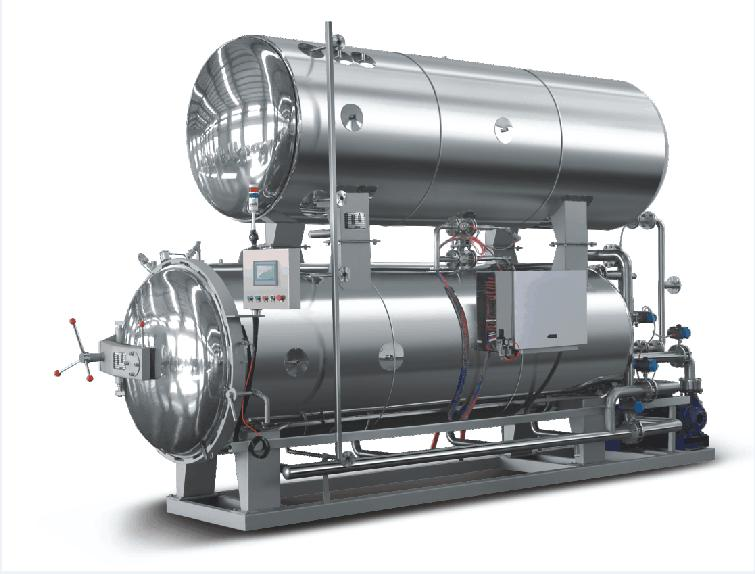

Autoclave has been widely used in food industry and pharmaceutical industry, such as juice, soup, milk, sauce, meat, fish,

vegetable, fruit, caned food, beer, etc.

It can be applied for many types package material, such as glass bottle,PP bottle, HDPE bottle, metal can, aluminum can, plastic

pouch, aluminum foil bag etc.