- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SH-10-0187

-

Place of Origin:

-

Guangdong, China, Guangdong China (Mainland)

-

Brand Name:

-

shuangxin

-

Name:

-

gear shaft

-

Certificate:

-

ISO/ ROHS/ heavy element

-

MOQ:

-

5000pcs

-

Finish:

-

nickel/zinc/tin/chrome/gold/silver plated,an

-

Process:

-

CNC automatic lathe/cnc machine

-

Tolerance:

-

+/-0.005 - +/- 0.02

-

Applications:

-

machinery,electrical/mechanical equipme

Quick Details

-

Weight (KG):

-

0.1

-

Material:

-

Customized, brass,bronze,copper,aluminum,steel,stai

-

Torque Capacity:

-

Customized

-

Model Number:

-

SH-10-0187

-

Place of Origin:

-

Guangdong, China, Guangdong China (Mainland)

-

Brand Name:

-

shuangxin

-

Name:

-

gear shaft

-

Certificate:

-

ISO/ ROHS/ heavy element

-

MOQ:

-

5000pcs

-

Finish:

-

nickel/zinc/tin/chrome/gold/silver plated,an

-

Process:

-

CNC automatic lathe/cnc machine

-

Tolerance:

-

+/-0.005 - +/- 0.02

-

Applications:

-

machinery,electrical/mechanical equipme

|

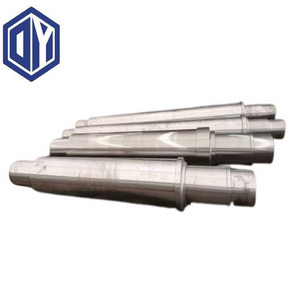

Product Name

|

customized high hardness forged steel shaft for metallurgy and shipbuilding,dongguan OEM top quality steel spline shaft

|

|

Material

|

Stainless steel : 303, 304, 316, 412,201,202 etc

Steel: Carbon steel/ die steel, C.R.S etc Aluminum alloy: 6061, 6063, 5052, 2017, 7075,etc Brass alloy:3602, 2604, H59, H62, copper,phosphor bronze,etc Plastic:Nylon,PP,POM,etc Other materials are available |

|

SURFACE TREATMENT

|

Anodizing

, Polishing, Powder coating, Passivation, Sandblasting, Nickal plating,Zinc plating, Chrome plating, Heat treatment, Oxidation

,laser engraved logo

.

|

|

Produce Progresses

|

CNCTurning ,CNC Milling ,CNC Lathe etc.

|

|

EQUIPMETS

|

CNC punching machines, CNC milling machines, CNC turning machines,CNC machining center, Automatic lathes, Linear cutting, Grinding machine etc.

|

|

APPLOCATION

|

Electronic, auto, electric appliance, electrical machine, toy, medical treatment spare metal parts,loudspeaker box, furniture and fitness equipment and other industries.

|

|

MAIN MARKETS

|

U.S.A, UK, Spain, Germany, Italy, Switzerland, etc

|

|

FACTORY OR TRADE COMPANY

|

We are a manufacturing factory.

|

◣

Six Reasons for Choosing Us

◢

1.

First-hand factory price:

We are factory, not trading company.

2.

Rich experience:

We have provided OEM/ODM and assembling service since 2000.

3.

Good technology support:

senior and professional engineers with more than 10 years experience

4.

Small/Low MOQ is accepted.

5.

100% inspection

before delivery.

6.

One-stop service:

including cnc turning, cnc milling, stamping, punching, spring, bending, welding, drilling, tapping, wire cutting, screw etc. ( Not only that, we could make the produce molds by ourself. )

◣ Our Service ◢

Manufacture / OEM

Design / ODM

Our professional engineers could design according to

your detail requirements or concepts

.

Beside, we also can provide relevant design advice based on our experiences, to reduce cost for you and help you complete a better design .

Assembly Service

*You send us drawings, samples or dimension ;

*We conduct project evaluation and provide you with design drawing;

*We make samples and send them to you;

*We start making products and then send them to you;

*The entire order has been completed!

|

Packaging

|

1. Inner packaging: PP bag, bubble bag, plastic wrap etc.

2. Outer packaging: carton, wooden case, pallet etc. 3. Customized packaging. |

|

Shipping

|

1. Shipments for light parts are via DHL,TNT,UPS,or Fedex etc.

2. Heavy weight and large size are via sea transportation . 3. According to customers' requirement. |

|

Port

|

Shenzhen

|

We are a 8500-square-meter factory located in Dongguan, China.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.