Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CAISU

-

Year:

-

2020

-

Voltage:

-

380V , 50Hz or Customized

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

16

-

Weight:

-

20000 KG

-

Product Name:

-

65/132 Plastic sheet making machine

-

Raw material:

-

PVC PP PE WPC PET

-

Processing Type:

-

Extruding Equipment

-

Control system:

-

Automatic Control System

-

State:

-

Second-hand

-

Screw type:

-

Single Screw

-

Factory visit:

-

Support

-

Advantage:

-

Affordable Price

-

Producr Species:

-

Rich

-

Feature:

-

High Production Efficiency

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CAISU

-

Year:

-

2020

-

Voltage:

-

380V , 50Hz or Customized

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

16

-

Weight:

-

20000 KG

-

Product Name:

-

65/132 Plastic sheet making machine

-

Raw material:

-

PVC PP PE WPC PET

-

Processing Type:

-

Extruding Equipment

-

Control system:

-

Automatic Control System

-

State:

-

Second-hand

-

Screw type:

-

Single Screw

-

Factory visit:

-

Support

-

Advantage:

-

Affordable Price

-

Producr Species:

-

Rich

-

Feature:

-

High Production Efficiency

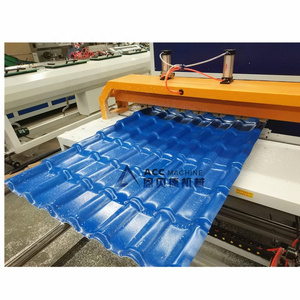

Products Description

Plastic Sheet Making Machine:

The screw adopts a mutation screw design, with less fine points, high output, uniform plasticization, flat three-roll calendering design, roller temperature adjustable, high surface gloss, convenient machine operation, easy to adjust, sheet thickness using thousands of points of positioning, cutting using automatic meter cutting device, winder using tension design, winding flat, high degree of automation, making production more convenient and efficient.

Plastic sheet production line process principle:

Plastic pellet - extruder: raw material melting and plasticization - quick change filter screen - extrusion die forming extrusion - three-roll calender - cooling setting device - cutting mechanism - traction transmission - shearing device.

|

Extruder model

|

SJSZ65/132

|

|

Motor power(kw)

|

16kw

|

|

Screw diameter(mm)

|

132

|

|

Weight(Kg)

|

15000

|

|

Screw Design

|

Single-screw

|

|

Sheet Width

|

600mm

|

|

Sheet Thickness

|

0.5-2mm

|

Details Images

Hot Searches