- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KBM

-

Product name:

-

Metal Spinning Part

-

Surface treatment:

-

Natural anodized/Black anodized/Black painted/White painted

-

Type:

-

Wire Rope Clip

-

Application:

-

Lighting Hardware Fittings

-

MOQ:

-

500pcs

-

Sample:

-

Free Sample

Quick Details

-

Material:

-

Aluminum

-

Shape:

-

Round

-

Design Style:

-

Modern, EUROPEAN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KBM

-

Product name:

-

Metal Spinning Part

-

Surface treatment:

-

Natural anodized/Black anodized/Black painted/White painted

-

Type:

-

Wire Rope Clip

-

Application:

-

Lighting Hardware Fittings

-

MOQ:

-

500pcs

-

Sample:

-

Free Sample

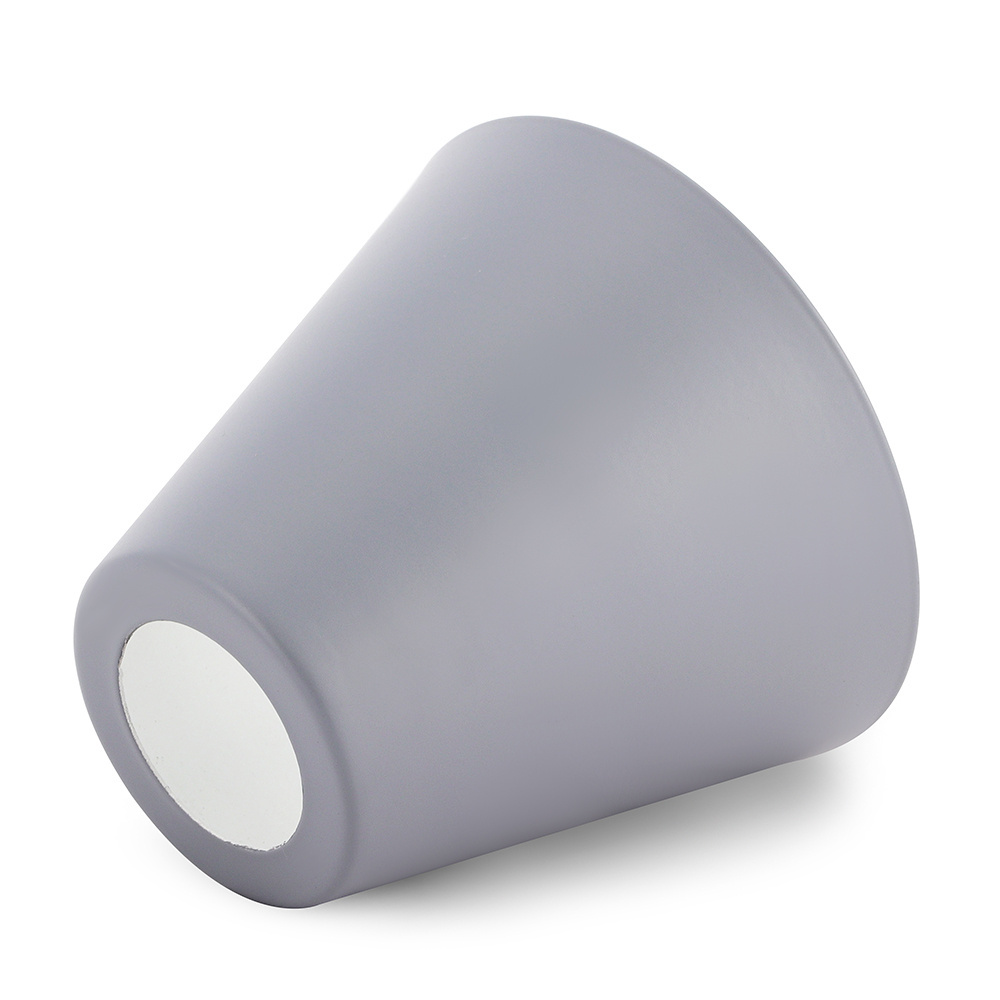

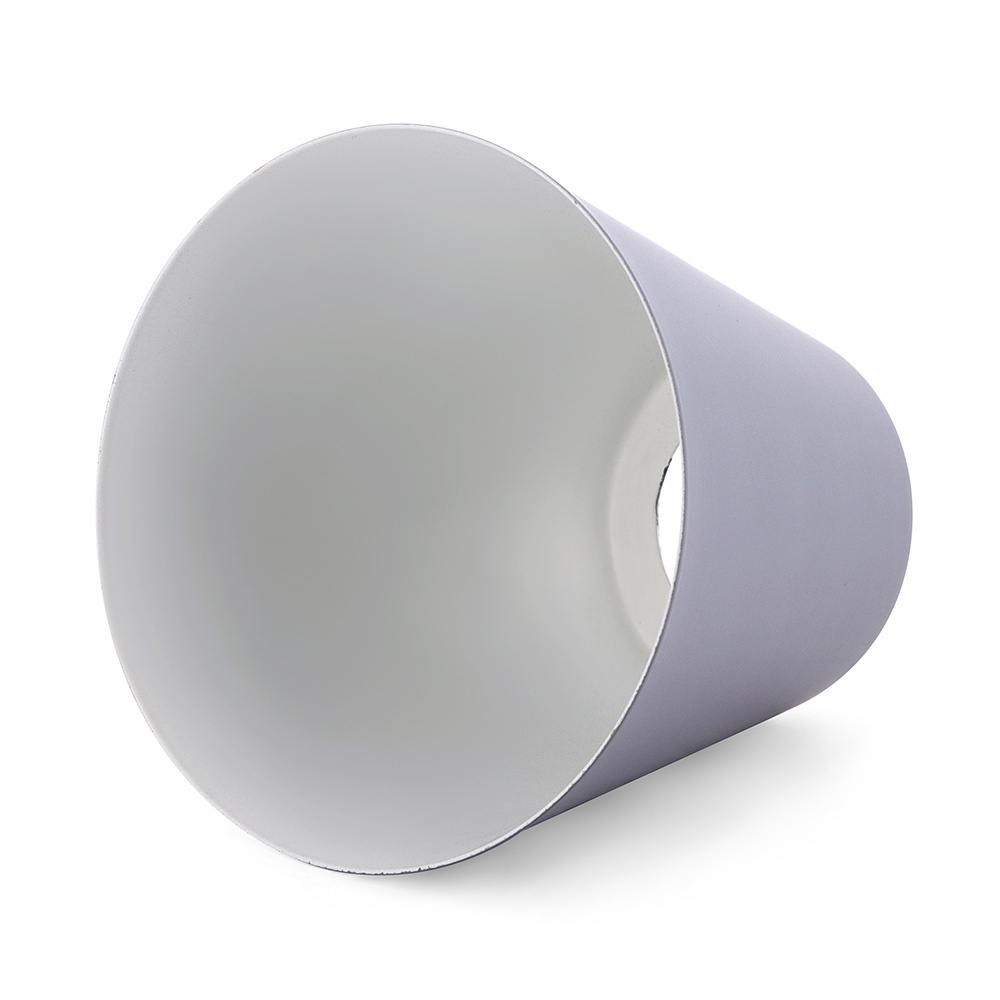

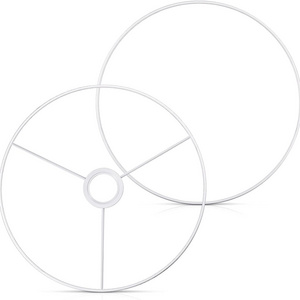

Products Description

Spinning for lighting parts

The definition of spinning:

Spinning is to fix the flat plate or hollow blank on the mold of the spinning machine. While rotating the spindle of the Lathe,

press the blank with a rotating wheel or a rod to make local plastic deformation. Spinning is a special forming method. The spinning, flanging, shrinking, bulging and crimping processes of various shapes of the rotating body can be completed by a spinning method.

Advantage:

1) spinning equipment is simple and flexible, and has great flexibility.

2) There are some complicated shapes, while punching is difficult or impossible to complete, it may suitable for spinning.

3) High material utilization rate and low production cost. Compared with machining, it can save materials by 20%-50% and cost by 30%-70%.

4) Spinning parts have high dimensional accuracy and surface roughness is easy to guarantee. In addition, the parts with spin forming have good fatigue resistance, yield point, tensile strength and hardness are greatly improved.

The definition of spinning:

Spinning is to fix the flat plate or hollow blank on the mold of the spinning machine. While rotating the spindle of the Lathe,

press the blank with a rotating wheel or a rod to make local plastic deformation. Spinning is a special forming method. The spinning, flanging, shrinking, bulging and crimping processes of various shapes of the rotating body can be completed by a spinning method.

Advantage:

1) spinning equipment is simple and flexible, and has great flexibility.

2) There are some complicated shapes, while punching is difficult or impossible to complete, it may suitable for spinning.

3) High material utilization rate and low production cost. Compared with machining, it can save materials by 20%-50% and cost by 30%-70%.

4) Spinning parts have high dimensional accuracy and surface roughness is easy to guarantee. In addition, the parts with spin forming have good fatigue resistance, yield point, tensile strength and hardness are greatly improved.

Product Paramenters

|

roduct name

|

Light Metal Spinning

|

|

Material

|

Aluminum

|

|

Application

|

Down lights, Ceiling Lights ect.

|

|

Dimensions

|

Customized Sizes

|

|

Delivery time

|

10~15 days

|

|

Sample

|

free sample

|

|

Surface treatment

|

RAW, White, Black

|

|

MOQ

|

500PCS

|

Details Images

Why Choose Us

Hot Searches