- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V, 3N/380V/50HZ

-

Power:

-

19kw

-

Dimension(L*W*H):

-

4000*1200*1300mm

-

Weight:

-

1200 KG

-

Machinery Function:

-

Making potato chips

-

Output product name:

-

potato chips, potato chips machine

-

Name:

-

Fully automatic potato chips production line

-

Usage:

-

Potato Chips Making Production Line

-

Heating method:

-

Electric Heating

-

Type:

-

Fully Automatic

-

Capacity:

-

200kg~1500kg/h

-

Material:

-

SUS304 Stainless Steel

-

Package:

-

Wooden Case

Quick Details

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

BR

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220V/380V, 3N/380V/50HZ

-

Power:

-

19kw

-

Dimension(L*W*H):

-

4000*1200*1300mm

-

Weight:

-

1200 KG

-

Machinery Function:

-

Making potato chips

-

Output product name:

-

potato chips, potato chips machine

-

Name:

-

Fully automatic potato chips production line

-

Usage:

-

Potato Chips Making Production Line

-

Heating method:

-

Electric Heating

-

Type:

-

Fully Automatic

-

Capacity:

-

200kg~1500kg/h

-

Material:

-

SUS304 Stainless Steel

-

Package:

-

Wooden Case

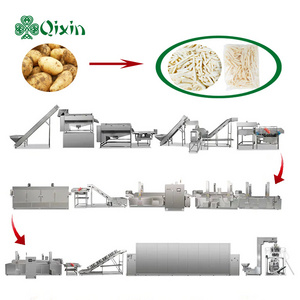

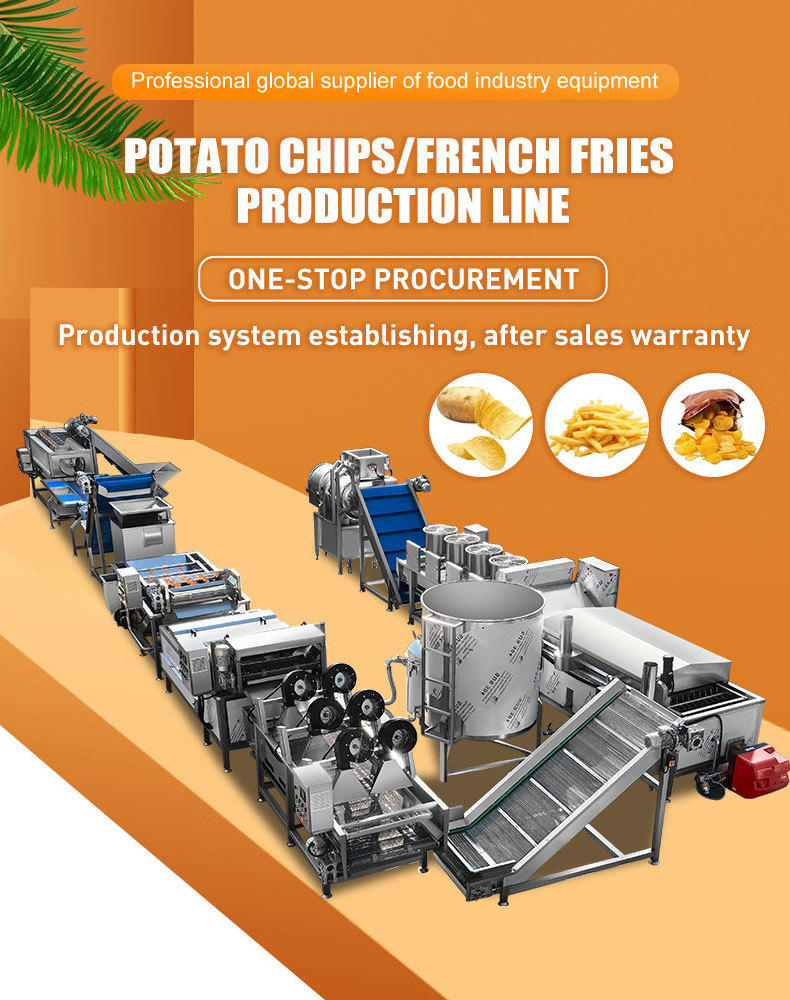

Fully Automatic Potato Chips Production Line Factory Potato Chips Making Machine

Products Advantage

1. Process capacity (finished capacity 100kg/h to 2000kg/h) and work flow can be customized.

2. All equipment are made of SUS304 stainless steel, electrical apparatus element is Schneider brand.

3. Heating method: Electric heating, Gas heating or Diesel heating (equipped with RIELLO or BALTUR burner), etc.

4. The size of French fries and the thickness of potato chips are adjustable.

5. For French fries line, we have special equipment to remove the unqualified fries.

6. With special designed fryer, quick heating and energy saving, enabled good performance.

|

No.

|

Machine Name

|

Function

|

||

|

1

|

PVC Elevator

|

For elevating and conveying fresh potatoes into the next washing peeling machine

|

||

|

2

|

Potato Washing and Peeling Machine

|

Thoroughly washing and peeling the potatoes

|

||

|

3

|

Sorting Conveyor

|

For manually disposing the uncleaned places and selecting the defective potatoes

|

||

|

4

|

Fries Cutting Machine

|

Sliced potato chips, thickness 1.5-5mm can be customized

|

||

|

5

|

Bubble Washing Machine

|

Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch

|

||

|

6

|

Blanching Machine

|

Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the fries

|

||

|

7

|

Vibration Dewatering Machine

|

Through vibration to remove the surface water and also to transport the fries uniformly to the next machine

|

||

|

8

|

Air Drying Machine

|

Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil

jumped phenomenon

|

||

|

9

|

Elevating Conveyor

|

For elevating and conveying the fries into next fryer machine

|

||

|

10

|

Continuous Frying Machine

|

For quick frying the fries around 40 seconds in 180°oil to avoid the adhesion and extend the shelf life

|

||

|

11

|

Vibration Deoiling Machine

|

Through vibration to achieve deoiling purpose, and also to convey the fries uniformly to next machine

|

||

|

12

|

Pre-cooling Machine

|

Through high pressure wind blowing for pre-cooling and deoiling the fries

|

||

|

13

|

Seasoning Machine

|

Season fried potato chips and season them evenly

|

||

|

14

|

Automatic Packing Machine

|

For packing the finished potato chips

|

||

|

Note: The output heating method and voltage can be customized according to the customer's choice.

|

|

|

||

Shanghai Huilai Machinery Co., Ltd. is a professional global food industry equipment supplier. The company specializes in R&D and production of potato chips and fries production lines, meat processing equipment, fruit and vegetable processing equipment, fried snack equipment, etc.

The company has CE and ISO9000(1)-2000 international quality management system certification, and in accordance with the QS standard food enterprise. After 15 years of hard work and innovation, "BR" brand machines have been exported to overseas and are well received by consumers.

Q:Are you a trading company or a factory?

A:We are a factory with more than 10 years of experience in food technology.

Q:How do you guarantee the quality of the machine?

A: We have export experience for 8 years and customers who bought our machine have tested the machine before it was shipped .

Q:Can the voltage of the machine be adapted ?

A:We can adapt the machine to your needs to match your local voltage.

Q:Can you ship the machine to my address?

A:Yes, we support shipping and air transportation, as well as door-to-door service.

Q:Can I go to China and visit your factory?

A:Sure, we are in Shandong, China, welcome to our factory.

Q:Do you have operation manual with the machine?

A:Yes, of course, it is in English version.

Q:Can you offer us the necessary paper to do the customs clearance?

A:Yes, we will send you the commercial invoice, packing list, bill of lading and we'll also meet your other request.

Q:How about the packing?

A:Outside Package: Wooden packing case as export standard ; Inside Package: Stretch film

Hot Searches