- Product Details

- {{item.text}}

Quick Details

-

Material:

-

steel

-

Weight:

-

1000kg

-

Size:

-

700*450 *820mm

-

Power:

-

5-50KW

-

Weight (KG):

-

1000 kg

-

Product name:

-

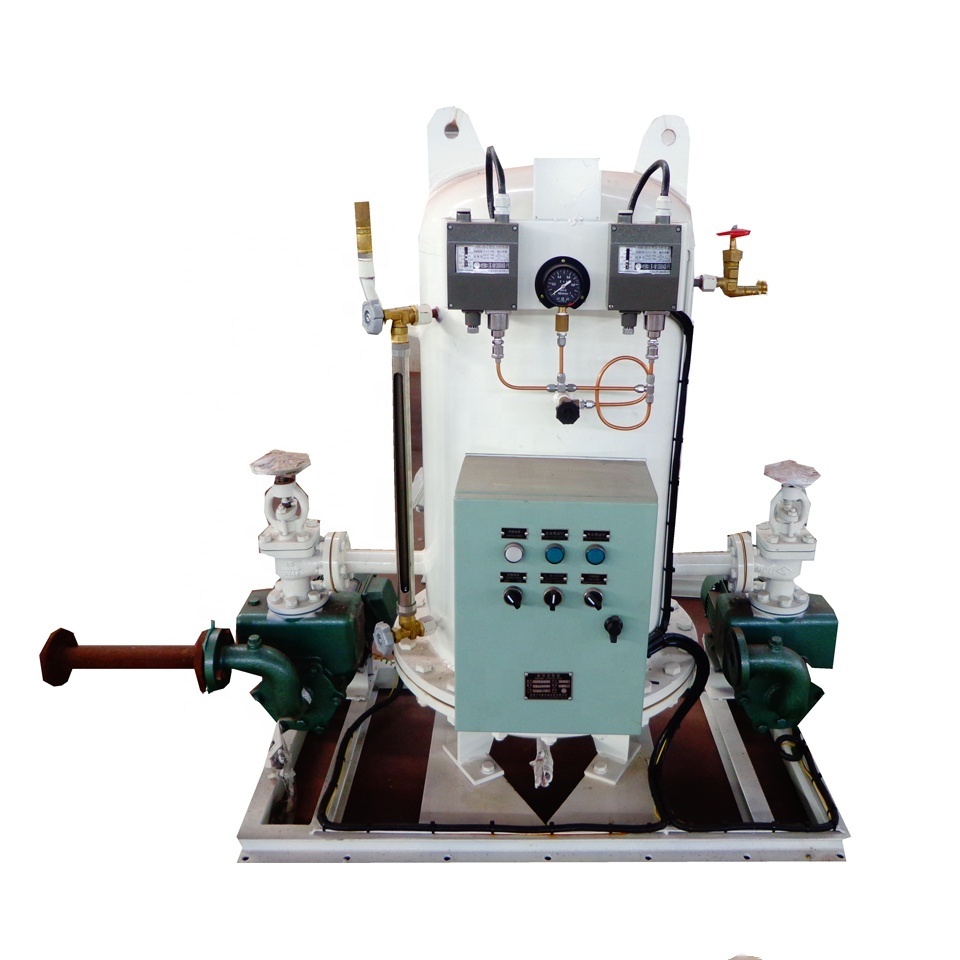

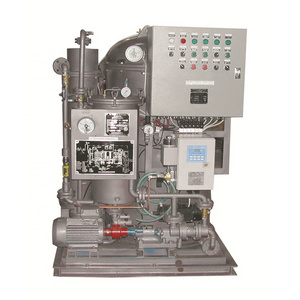

Marine oil water separator

-

Application:

-

marine ship vessel boat

-

Certificatie:

-

MED, MEPC, EC, CCS, DNV, GL

-

MOQ:

-

1 Set

-

key words:

-

MED, MEPC, EC, CCS, DNV, GL

-

Quality warranty:

-

1 year

-

Oil content of the discharged water:

-

15ppm

-

Electrical System:

-

AC 380V, 50Hz, AC 220V

-

Model:

-

SINO-OWS0.25, 0.5, 1

-

Rated capacity (m3/h):

-

0.25, 0.50, 1.00

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

Quick Details

-

Core Components:

-

Oil-water separator

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Sino

-

Material:

-

steel

-

Weight:

-

1000kg

-

Size:

-

700*450 *820mm

-

Power:

-

5-50KW

-

Weight (KG):

-

1000 kg

-

Product name:

-

Marine oil water separator

-

Application:

-

marine ship vessel boat

-

Certificatie:

-

MED, MEPC, EC, CCS, DNV, GL

-

MOQ:

-

1 Set

-

key words:

-

MED, MEPC, EC, CCS, DNV, GL

-

Quality warranty:

-

1 year

-

Oil content of the discharged water:

-

15ppm

-

Electrical System:

-

AC 380V, 50Hz, AC 220V

-

Model:

-

SINO-OWS0.25, 0.5, 1

-

Rated capacity (m3/h):

-

0.25, 0.50, 1.00

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

General specifications:

0.25m3/h, 0.5m3/h, 1m3/h oil water separator

|

Application

This device can be used to treat oily bilge water in order to make it reach the requirements of IMO.MEPC.107 (49) resolution,

which is also called 15ppm bilge separator. It contains type approved 0.5M3 15ppm bilge water separator, 15ppm bilge alarm and Automatic shut down Device. |

|

|

|

|

||||

|

Principle

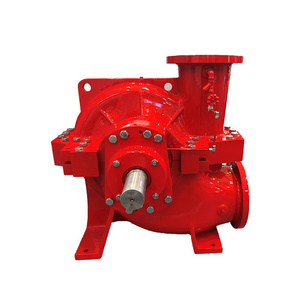

The device adopts the combination of 1st stage, cone plate gravity and coalesce separation; 2nd stage, membrane permeation in order to make the treated bilge water to reach the requirements of discharge standard of the resolution of IMO MEPC.107 (49).

The liquid coming out of Piston pump is adsorbed and filtered by the 2nd stage fiber filter to reach the discharge standard.

|

|

|

|

|

||||

|

System flow

The bilge oily water comes into the 1st coalescer through Seawater initial filter and bottom valve, floating ball non-returned valve. There is an oil chamber in the tope of separator. Most of the oil in the bilge oily water floats to the surface of chamber because of the effects of small gravities. The tiny oil drops gather and coalesce in the cone wave plate which is made of hydrophilic and oil-left materials and floats in the main and then adverse current.

When the oil accumulates to interface level in the top chamber of the 1st coalescer, manual oil drainage is required。 It resets automatically after the oil is discharged and it again starts to treat the oily bilge water.

The effluent already treated by the 1st coalescer comes into the 2nd filter and is treated again, then is discharged to overboard.

Then be discharged through sea valve finally.

As for the first operation, the containers and pipes are to be filled with water. When the water comes to a valve and flows out, this valve is to be shut. When the water comes to the air cock that means the water is filled fully.

Oil content meter, i.e.15ppm Bilge Alarm; Refer to the instruction book of it.

Caution: This device uses high voltage power source and may cause the imminent hazardous injury caused by electric shock. The door of electric control box should not be opened at presumptuously. When doing electrical repair, make sure the power is cut off and the repair is to be done by professionals.

|

|

|

|

|

||||

Hot Searches