- Product Details

- {{item.text}}

Quick Details

-

Warranty of core components:

-

1 years

-

Weight (KG):

-

20000 KG

-

Name:

-

Tyre Recycle Plant Waste Car Tire Recycling Line

-

Capacity:

-

500-5000kg/hour

-

Raw material:

-

Car/truck/bus/mining tires

-

Output Product:

-

50-120mm rubber shreds/10-15mm rubber mulch

-

Final Product:

-

1-7mm rubber crumb /30-120mesh rubber powder

-

Application:

-

Rubber crumb plant / Rubber powder plant

Quick Details

-

Place of Origin:

-

Henan

-

Brand Name:

-

Kowloon Machinery

-

Marketing Type:

-

New Product 2024

-

Warranty of core components:

-

1 years

-

Weight (KG):

-

20000 KG

-

Name:

-

Tyre Recycle Plant Waste Car Tire Recycling Line

-

Capacity:

-

500-5000kg/hour

-

Raw material:

-

Car/truck/bus/mining tires

-

Output Product:

-

50-120mm rubber shreds/10-15mm rubber mulch

-

Final Product:

-

1-7mm rubber crumb /30-120mesh rubber powder

-

Application:

-

Rubber crumb plant / Rubber powder plant

Waste Car Tire Recycling Line Truck Tyre Recycle Plant

Products Description

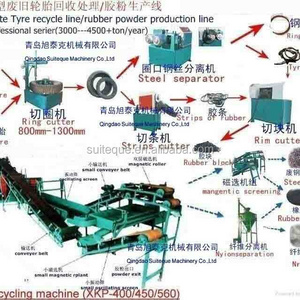

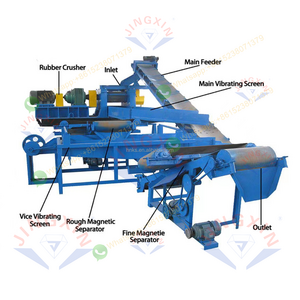

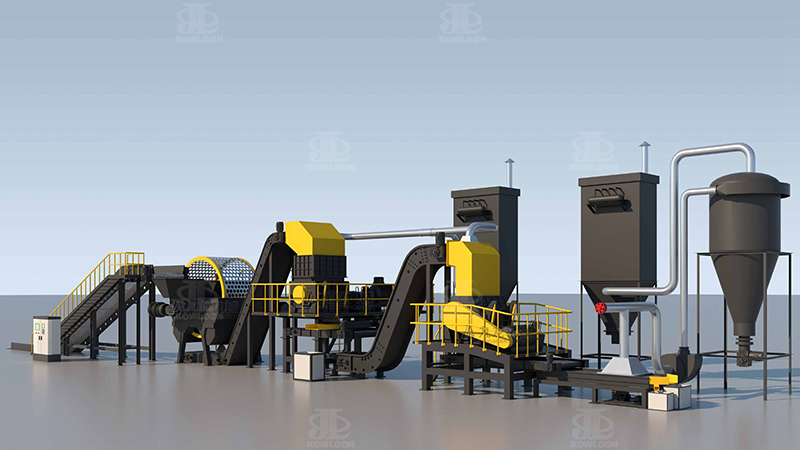

Kowloon Machinery offer both standard and customized tyre recycling solutions depending on your requirements for input tyre type, production capacity, and output size/purity. The standard solutions for tyre recycling have capacities ranging from 500 – 5000 kg input/production hour depending on your needs. These are typically the starting point when customizing solutions e.g. for larger capacities.The systems and machines are developed based on ambient mechanical technique for size reduction and separation. No melting or chemical treatment required.

Tyre Recycle Plant Waste Car Tire Recycling Line

Tyre recycling is the process of downsizing whole tyres of any type for the purpose of reusing the material for other purposes. The materials most sought after in tyre recycling are clean rubber and steel wire.

Applicable Materials

Bicycle tires, Electric vehicle tires, Motorcycle tires, Passenger car tires, Bus tires, Off-road vehicle tires, Agricultural and Forestry machinery tires, Light truck tires, Construction machinery tires, Industrial vehicle tires.

The Final Products

50-120mm rubber shreds

10-15mm rubber mulch

1-7mm rubber crumb

30-120mesh rubber powder

Old Tire Rubber Granule Production Line For Rubber Powder Recycle can crush waste tires or rubber products into rubber granules and powder to realize the recycling and reusing of waste rubbers. As a professional manufacturer, we can provide you the best solution based on your different raw materials.

Technical Parameters

|

Item

|

Raw material

|

Output Product

|

Output Capacity

|

|

TDF tire shreds plant

|

|

50-120mm rubber shreds

|

|

|

Steel free rubber mulch plant

|

|

10-15mm rubber mulch

|

|

|

Rubber crumb plant

|

|

1-7mm rubber crumb

|

|

|

Rubber powder plant

|

|

30-120mesh rubber powder

|

|

|

Model

|

JLTD1200

|

JLTD1600

|

|

Power

|

22kw

|

37kw

|

|

Route of hydraulic cylinder

|

1200mm

|

1600mm

|

|

Max tire application range

|

≤1200mm diameter

|

1200-1600mm diameter

|

|

Working pressure

|

15tons

|

18tons

|

|

Working capacity

|

30-60tires/hour

|

30-60tires/hour

|

|

Dimension (L*W*H)

|

4100*1300*1750mm

|

5000*1500*1900mm

|

|

Weight

|

2000kg

|

3500kg

|

|

Model

|

JLTS1200D

|

JLTS1500D

|

JLTS2000D

|

JLTS2600D

|

|||

|

Motor

|

45kw+45kw

|

55kw+55kw

|

75kw+75kw

|

90kw+90kw /

110kw+110kw

|

|||

|

Motor brand

|

WN/Siemens/ABB/WEG

|

|

|

|

|||

|

Gearbox

|

2units, planetary type, motor direct connected, gear driven

|

|

|

|

|||

|

Shredder chamber

size (inner)

|

1180*1050mm

|

1480*1050mm

|

1920x1250mm

|

2520*1450mm

|

|||

|

Rotor speed

|

8-12rpm

|

8-12rpm

|

6-8rpm

|

6-8rpm

|

|||

|

Shredder blade

|

Dia.530mm

|

Dia.530/560/600mm

|

Dia.560/600mm

|

Dia.720mm/900mm

|

|||

|

Screen hole size

|

Dia.50mm-200mm

|

|

|

|

|||

|

Dimension

|

3.2x2x1.9m

|

4x1.7x2.4m

|

5.5x3.5x3m

|

6.2x4.3x3.3m

|

|||

|

Weight

|

16500kg

|

18000-22000kg

|

25000-28000kg

|

32000-34000kg

|

|||

|

Model

|

JLRS800

|

JLRS1000

|

JLRS1200

|

JLRS1500

|

|

Main motor

|

55kw

|

75kw

|

90kw

|

110kw

|

|

Rotor diameter

|

460mm

|

460mm

|

670mm

|

670mm

|

|

Moving blade

|

36pcs, H13K

|

42pcs, H13K

|

36pcs, H13K

|

48pcs, H13K

|

|

Bottom blade

|

12pcs, H13K

|

14pcs, H13K

|

12pcs, H13K

|

16pcs, H13K

|

|

Hydraulic open assistant

|

2.2kw

|

2.2kw

|

3kw

|

3kw

|

|

Self-discharge belt conveyor

|

2.2kw

|

2.2kw

|

2.2kw

|

3kw

|

|

Magnet separator

|

1.5kw

|

1.5kw

|

1.5kw

|

2.2kw

|

|

Dimensions

|

3.35*2.02*3.05m

|

3.5*2.02*3.05m

|

4.05*2.35*3.8m

|

4.55*2.45*3.8m

|

|

Model

|

JLSP800

|

JLSP1000

|

JLSP1200

|

JLSP1500

|

|||

|

Main motor

|

55kw

|

75kw

|

90kw

|

110kw

|

|||

|

Rotor diameter

|

600mm

|

600mm

|

700mm

|

700mm

|

|||

|

blade

|

Made of H13, solid blade

|

42pcs, H13K

|

36pcs, H13K

|

48pcs, H13K

|

|||

|

Hydraulic station

|

2.2kw

|

2.2kw

|

3kw

|

3kw

|

|||

|

Self-discharge belt conveyor

|

2.2kw

|

2.2kw

|

3kw

|

3kw

|

|||

|

Screen hole size

|

Dia.3-7mm

|

1.5kw

|

1.5kw

|

2.2kw

|

|||

|

Dimensions

|

3.35*1.65*2.95m

|

3.25*1.85*2.95m

|

2.7*2.05*3.45m

|

2.7*2.4*3.45m

|

|||

|

Model

|

JLRM280

|

|

Capacity

|

60-85kg/h

|

|

Feeding material

|

1-10mm rubber granules

|

|

Size of output granules

|

30-120mesh

|

|

Total Power

|

28kw

|

|

Temperature of working

|

≤80℃

|

|

Dimension(L*W*H)

|

1500*1000*1200mm

|

|

Weight

|

1000kg

|

Installed Projects

Packaging and Shipping

Hot Searches