- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

FengWang

-

Power:

-

220Kw

-

Dimension(L*W*H):

-

L60m-140m * W2 * H8-14m

-

Weight:

-

50

-

Name:

-

Household Gloves Production Line

-

Material:

-

Stainless Steel and Q235B

-

Color:

-

Customizable

-

Size:

-

Customizable

-

Delivery Period:

-

Negotiate

Quick Details

-

Production Capacity:

-

7500-35000pcs/hr

-

Voltage:

-

380V

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

FengWang

-

Power:

-

220Kw

-

Dimension(L*W*H):

-

L60m-140m * W2 * H8-14m

-

Weight:

-

50

-

Name:

-

Household Gloves Production Line

-

Material:

-

Stainless Steel and Q235B

-

Color:

-

Customizable

-

Size:

-

Customizable

-

Delivery Period:

-

Negotiate

Product Overview

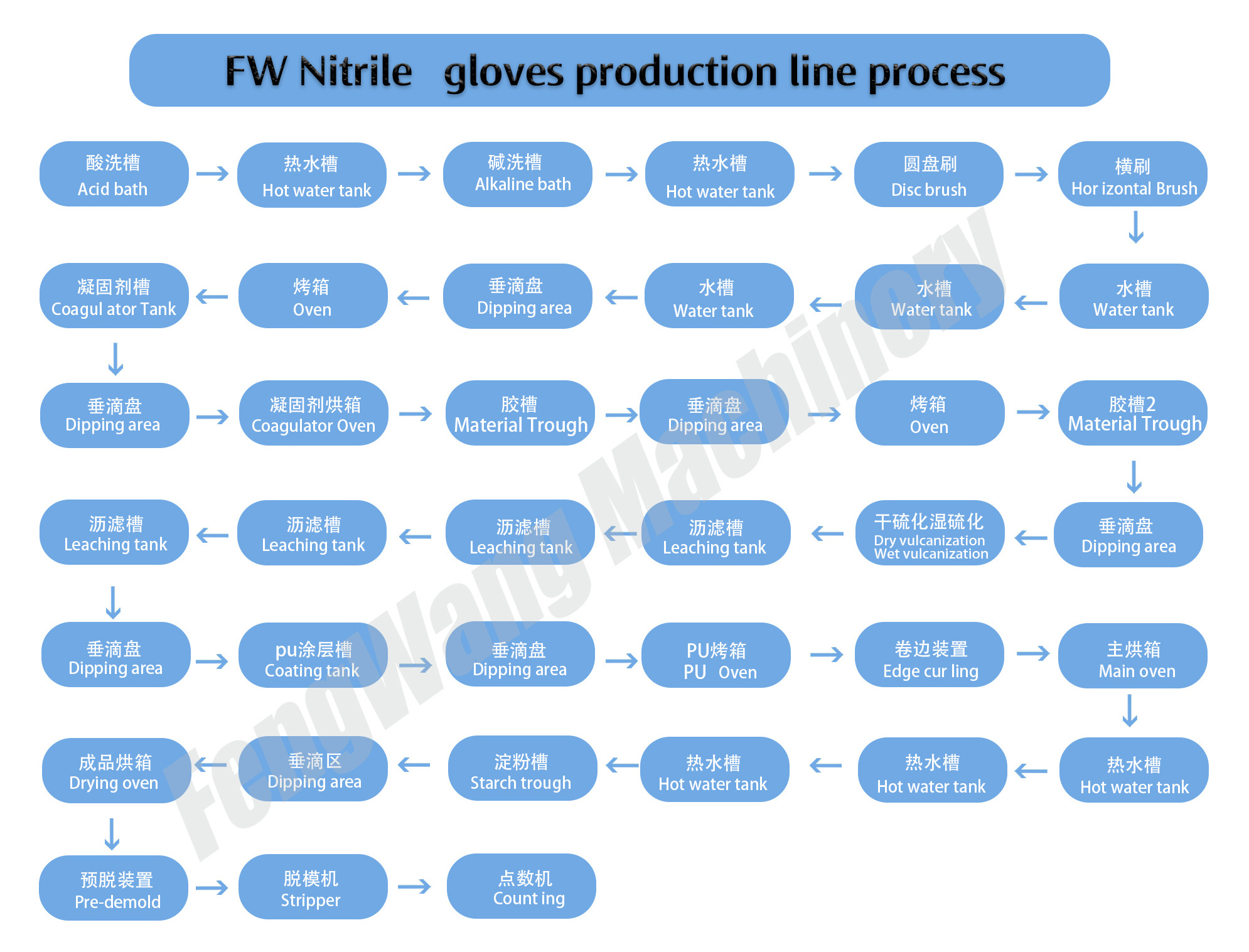

Nitrile gloves production line introduction

Nitrile glove production line with natural latex or synthetic rubber as the main raw material, with other chemicals as auxiliarymaterials. Hand molds are cleaned with acid and alkali, and then with water. The cleaned hand mold is soaked in hot water,heated,immersed in coagulant, dry and impregnated. After soaking, enter the oven for preliminary drying, rinse with hot water, andthen send to another oven for curing and drying molding. After removing the gloves, aerate or add water for inspection, wash and centrifuge. Dry before packing and send to finished product warehouse.

Nitrile glove production line:

|

Device Model

(Length*Width*Height)

|

Production line type

|

Capacity(pc/day)

|

||

|

50m*1.8m*6.5m

|

Single Mode

|

115000-120000

|

||

|

80m*1.8m*6.5m

|

Single Mode

|

190000-192000

|

||

|

80m*1.8m*7.5m

|

Single Mode

|

382000-384000

|

||

|

80m*1.8m*9.6m

|

Dual Mode

|

480000-482000

|

||

|

80m*1.8m*12m

|

Dual Mode

|

628000-630000

|

||

|

100m*1.8m*6.5m

|

Single Mode

|

240000-242000

|

||

|

100m*1.8m*7.5m

|

Dual Mode

|

518000-519000

|

||

|

110m*1.8m*6.5m

|

Single Mode

|

312000-315000

|

||

|

110m*1.8m*7.5m

|

Dual Mode

|

550000-552000

|

||

|

110m*1.8m*12m

|

Dual Mode

|

700000-725000

|

||

|

120m*1.8m*11m

|

Dual Mode

|

453000-456000

|

||

|

140m*1.8m*8m

|

Dual Mode

|

370000-372000

|

||

|

180m*1.8m*12m

|

Dual Mode

|

838000-840000

|

||

|

...

|

...

|

...

|

||

|

Different size production lines can be customized according to customer requirements

|

|

|

||

product show

Procurement process

Order Process

To make contact →Engineer confirms the size of customer's workshop→Desing plant layout plan

→Design product line drawings and confirm by both parties

→Buy steel, manufacture tank, tank and other parts for production line

→Shipment to customer plant

→The engineer came to the factory to guide the installation

→Commissioned finished product

→Design product line drawings and confirm by both parties

→Buy steel, manufacture tank, tank and other parts for production line

→Shipment to customer plant

→The engineer came to the factory to guide the installation

→Commissioned finished product

Our Advantages

Our advantage

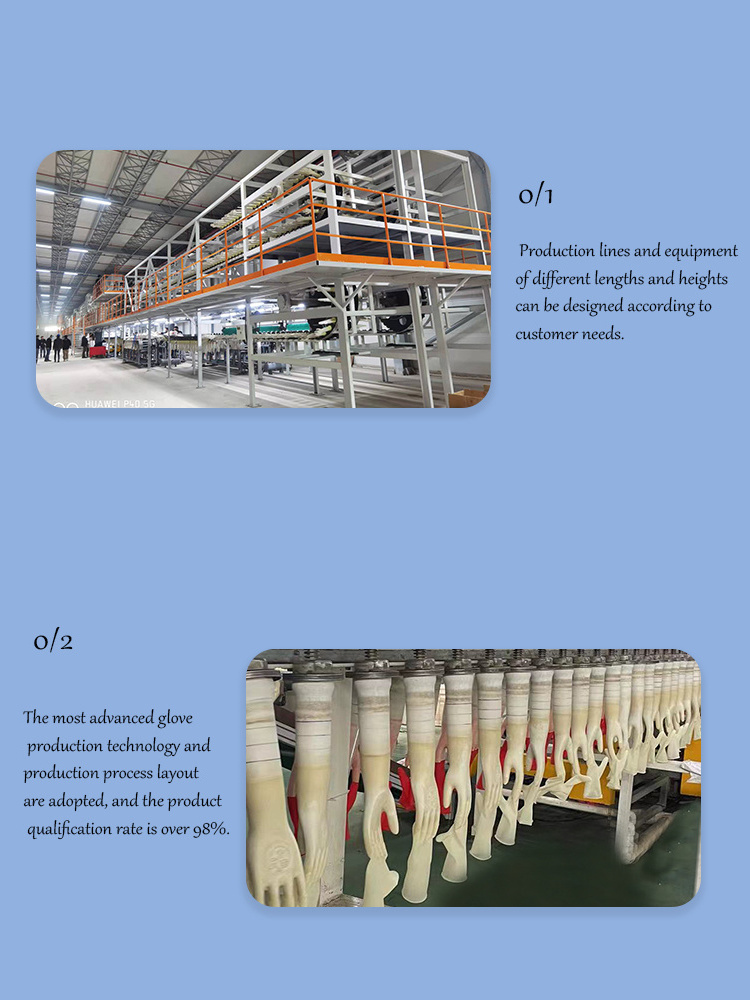

1.The most advanced glove production technology and production process layout are adopted, and the product qualification rate is over 98%.

2.TPU coating technology

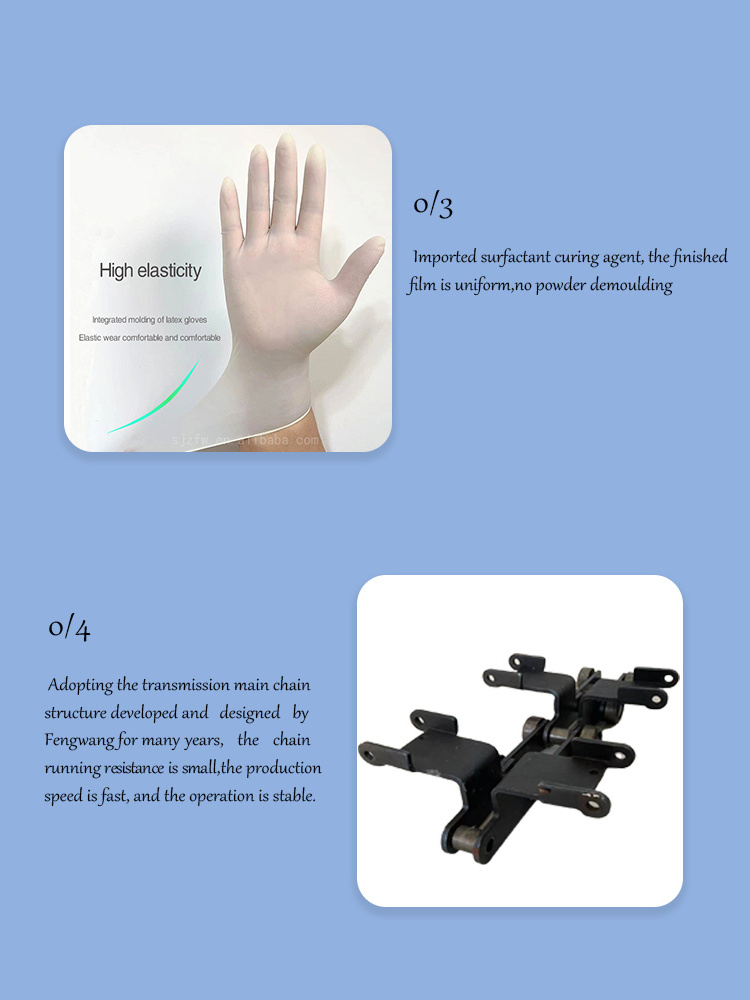

3.Imported surfactant curing agent, the finished film is uniform, no powder demoulding

4.Adopting the transmission main chain structure developed and designed by Fengwang for many years, the chain running resistance is small, the production speed is fast, and the operation is stable.

5.The main motor is dragged to solve the problems of dragging, synchronization difficulties, fault points, and maintenance difficulties.

6.The vertical hot air circulation oven is adopted, which saves energy by nearly 25% compared with other hot air circulation forms.

7.The technology used to clean the six-roller long-haired sanding mold of the splitter;

8.Die orientation and machine printing technology;

9.Various specifications of production, automatic adjustment on the same side, PU piping, long service life.

10.Production lines and equipment of different lengths and heights can be designed according to customer needs.

Hot Searches