- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WL

-

Model Number:

-

According to drawings

-

Place of Origin:

-

Henan, China

-

Product Name:

-

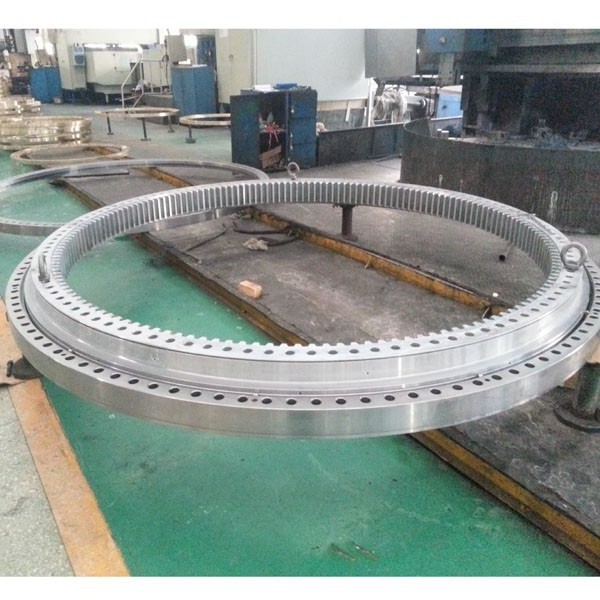

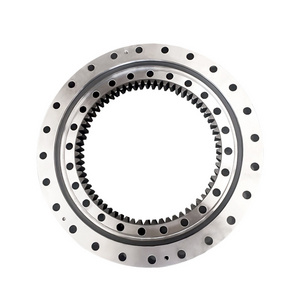

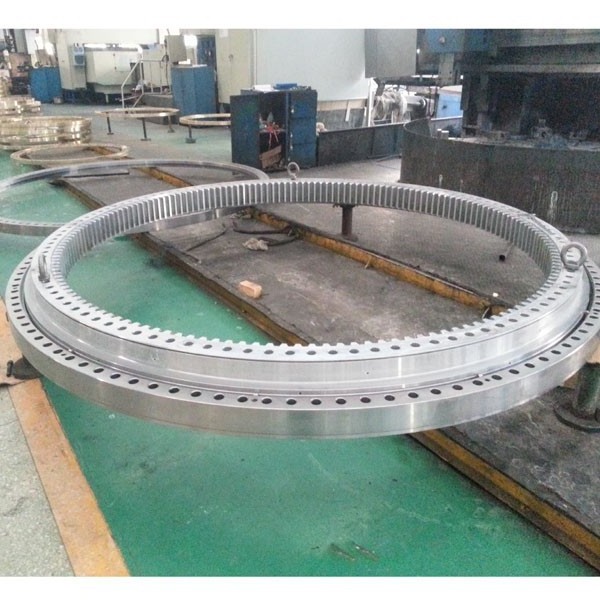

Customize 50Mn Large DiameterTurntable Slewing Bearing

-

Gear Type:

-

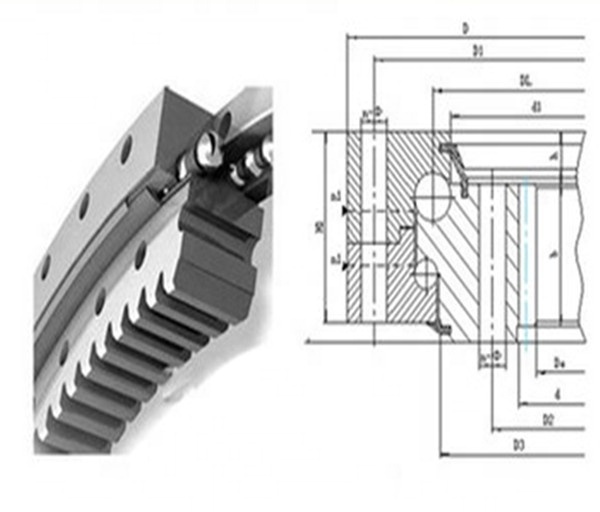

Internal gear/outside gear/no gear

-

Chemical Control:

-

Spectrograph

-

Defect Control:

-

UT, MT

-

Heat Treatment:

-

Anneal, Quenchining & Tempering

-

Surface Treatment:

-

Grinding

-

Application:

-

Heavy Excavator

-

Gear Accuracy:

-

MAX Grade 6

-

Certificate:

-

ISO9001-2015

-

Standard or Nonstandard:

-

Nonstandard

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Energy & Mining

-

Feature:

-

High quality

-

Seals Type:

-

Steel

-

Brand Name:

-

WL

-

Model Number:

-

According to drawings

-

Place of Origin:

-

Henan, China

-

Product Name:

-

Customize 50Mn Large DiameterTurntable Slewing Bearing

-

Gear Type:

-

Internal gear/outside gear/no gear

-

Chemical Control:

-

Spectrograph

-

Defect Control:

-

UT, MT

-

Heat Treatment:

-

Anneal, Quenchining & Tempering

-

Surface Treatment:

-

Grinding

-

Application:

-

Heavy Excavator

-

Gear Accuracy:

-

MAX Grade 6

-

Certificate:

-

ISO9001-2015

-

Standard or Nonstandard:

-

Nonstandard

Why Choose Us

Products Description

Product Description

Product name:

Customize Nonstandard Excavator 50Mn Large DiameterTurntable Slewing Bearing

We can produce large forging,casting and welding gears according to customer's drawings.According to the working conditions and clients' request,we also can do gear grinding,surface hardening,cemented and quenching,Nitriding and quenching,etc.

We can manufacture different type of gears according to drawing.

|

Materia

|

|

Carbon Steel , Alloy Steel

|

|

|

|||

|

Standard

|

|

ASTM DIN . EN GOST JIS ETC

|

|

|

|||

|

Structure

|

|

Forging , Casting and Welding

|

|

|

|||

|

Module of Gear

|

|

8-120

|

|

|

|||

|

Gear Grinding

|

|

MAX Module 24

|

|

|

|||

|

Diameter of Gear Wheel :

|

|

MAX 13 000 mm

|

|

|

|||

|

Diameter of Spiral Gear :

|

|

MAX . 2 200 mm

|

|

|

|||

|

Length of Gear Shaft :

|

|

MAX 5 000 mm

|

|

|

|||

|

OEM Service Offered

|

|

According to Customer Drawings

|

|

|

|||

|

Segments Gear Offered :

|

|

According to Customer Requests

|

|

|

|||

|

Heat Treatment

|

|

Q & T Case Hardening

|

|

|

|||

Related Products

About Us

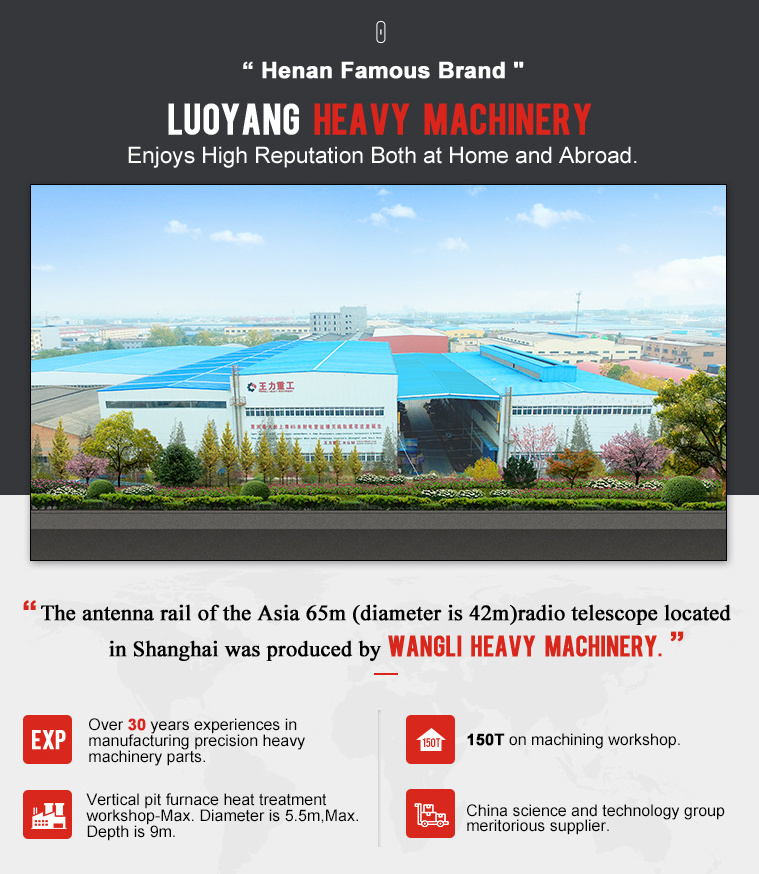

Luoyang Wangli Heavy Machinery Co, LTD is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts, including shafts, gears, sprockets, sheaves, couplings, bearing supports, castings and forgings etc. The products are mainly used for fields ofg, petroleum, cement, steel mill, power plant, sugar factory etc.

We have different specifications of oil forging presses,ring rolling machines,electric arc furnaces,thus we can provide variety of forging,casting and welding materials according to customer's requests.

Advantage of our Heat Treatment:

- Professional, specific furnace, single-minded

- Vertical pit furnace,keep the temperature uniformity during heating,+/-1℃

- Small deformation,little oxide layer,reduce material cost

- Different materials can be cooled at the good speed

- Large capacity, completed variety of quenching medium: oil,water,salt water,water based mixture.

Machining

We have the completed machining equipment,including horizontal lathe,vertical lathe,CNC boring and milling machine,CNC boring machine,deep hole drilling and boring machine,gear hobbing machine,

gear teeth grinding machine,grinding machine,etc.

Strictly quality inspection system can produce high quality products. For each order,we can provide report for material chemical components testing,UT testing,hardness,mechanical property testing(impact testing,yield strength testing,tensile strength testing),size inspection,etc.

In order to avoid the finish products rusted and damaged during the transportation ,we will design the right packing according to the shape,size and usage of the products.

R&D

We can provide technical support on new material,heat treatment and new manufacture process according customer’s working condition in order to improve lifespan of machinery parts.We have got a lot of patents on the spare parts of mill,cement rotary kiln,dragline excavator,rotor shafts.

Customer Visit

Our products have been exported to abroad for more than 10 years and 46 countries,such as

America,Australia,Russia,Pakistan,Thailand,Indian,Morocco,Romania,Spain,etc.

America,Australia,Russia,Pakistan,Thailand,Indian,Morocco,Romania,Spain,etc.

Hot Searches