1

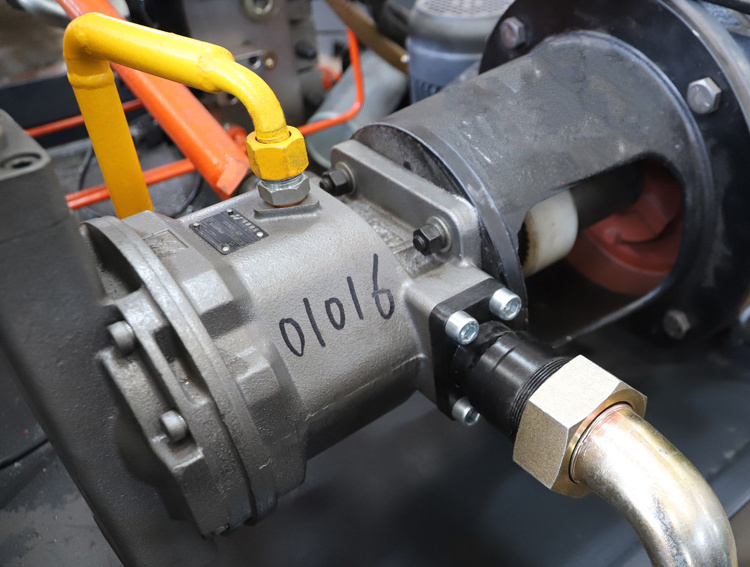

Oil Pump

(updated from YCY to SY)

The flange connection has a good sealing effect and prevents oil leakage.