- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Product name:

-

soap making machine

-

Application:

-

soap production

-

Keywords:

-

soap equipment

-

Machine name:

-

soap production line

-

Capacity:

-

1000KG/Hour soap plant

-

Type:

-

automatic soap making machine

-

Final products:

-

toilet soap production

-

Voltage:

-

380v 50HZ

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JASUN

-

Weight (KG):

-

60000

-

Marketing Type:

-

Hot Product 2021

-

Product name:

-

soap making machine

-

Application:

-

soap production

-

Keywords:

-

soap equipment

-

Machine name:

-

soap production line

-

Capacity:

-

1000KG/Hour soap plant

-

Type:

-

automatic soap making machine

-

Final products:

-

toilet soap production

-

Voltage:

-

380v 50HZ

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After Warranty Service:

-

Video technical support

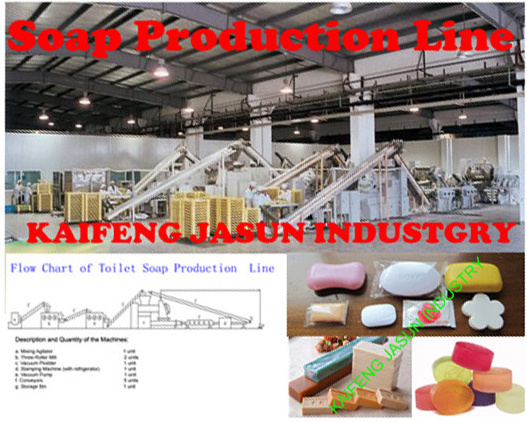

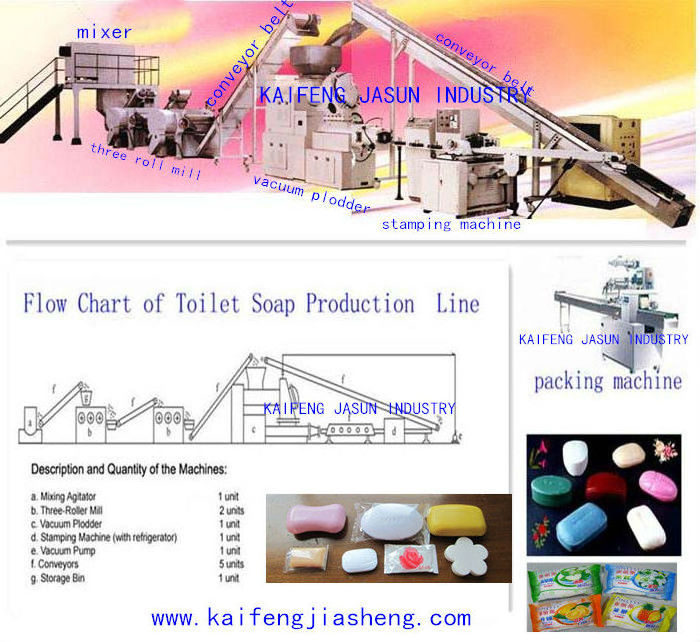

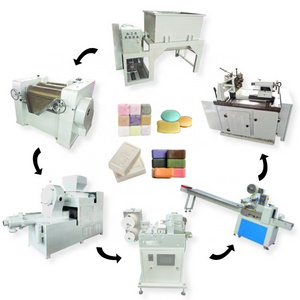

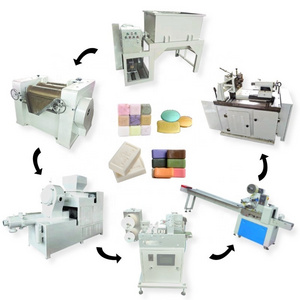

The finishing soap production line

1. Mixer

Used for mixing soap noodles and other additive(such as perfume).

2. Three Roller Mill

Three roller Mill grinds soap materials twice by different speed, make the soap structure tight and improve soap’s density and quality.

3. Vacuum Soap Plodder

Vacuum Soap Plodder is used to grind, refine and press soap material into soap bar.The above and below screws and two orifice plates press and refine the soap material and make the soap bar tight and the surface bright.The motor and the reducer are separated.The below screw speed is adjustable to regulate the production capacity.

4 . Soap Embossing & Cutting Machine

Used for cutting soap into bars and blocks. At the same time, the logo or pattern are stamped on the soaps.

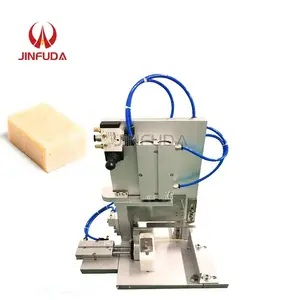

5.Soap Stamping Machine

The stamping machine is used to cut, shape and print the soap bar extruded from the former machine vacuum plodder.

6. Low Temperature Chiller

It is used to make the moulds cool so that the soap can demould easily.

7.Soap Packing machine

Used for packing soap

8. Conveyor Belt

It is used to transport soap materials or soap bar between two soap making machines.

9.Vacuum Pump

It is used to pull out the air and mousture in vacuum soap plodder.

The production process for laudnry soap

The process of making laundry soap starts with the mixing soap noodles. Then the mixed soap noodles enters in the three roll mill, where soap thin sheets are made. The sheet then converted into desired shape long strip soap by the plodding machine.Then the long strip soap are cut into the required size by cutting machine . Finally the soap bars gets packed by packing machine.

Usual Capacity:

Available complete set of laundry soap produciton line from 100KG/Hour to 3,000KG/hour,and 100KG/hour to 1000KG/H for toilet soap produciton line.

As many years experiences of soap making machines,we can provide soap making machine according to each buyer's special requirements.For more information about our machine,please visit http://www.kaifengjiasheng.com