- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX high rib roll forming machine

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7500*1700*1600Mm

-

Weight:

-

5 kg

-

Raw material:

-

Galvanized Steel Sheet

-

Color:

-

Customers Requirement

-

Usage:

-

Roof Tile Panel

-

Product name:

-

high rib roll forming machine

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# St

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Material:

-

Color Steel Galvanized Plate

-

Name:

-

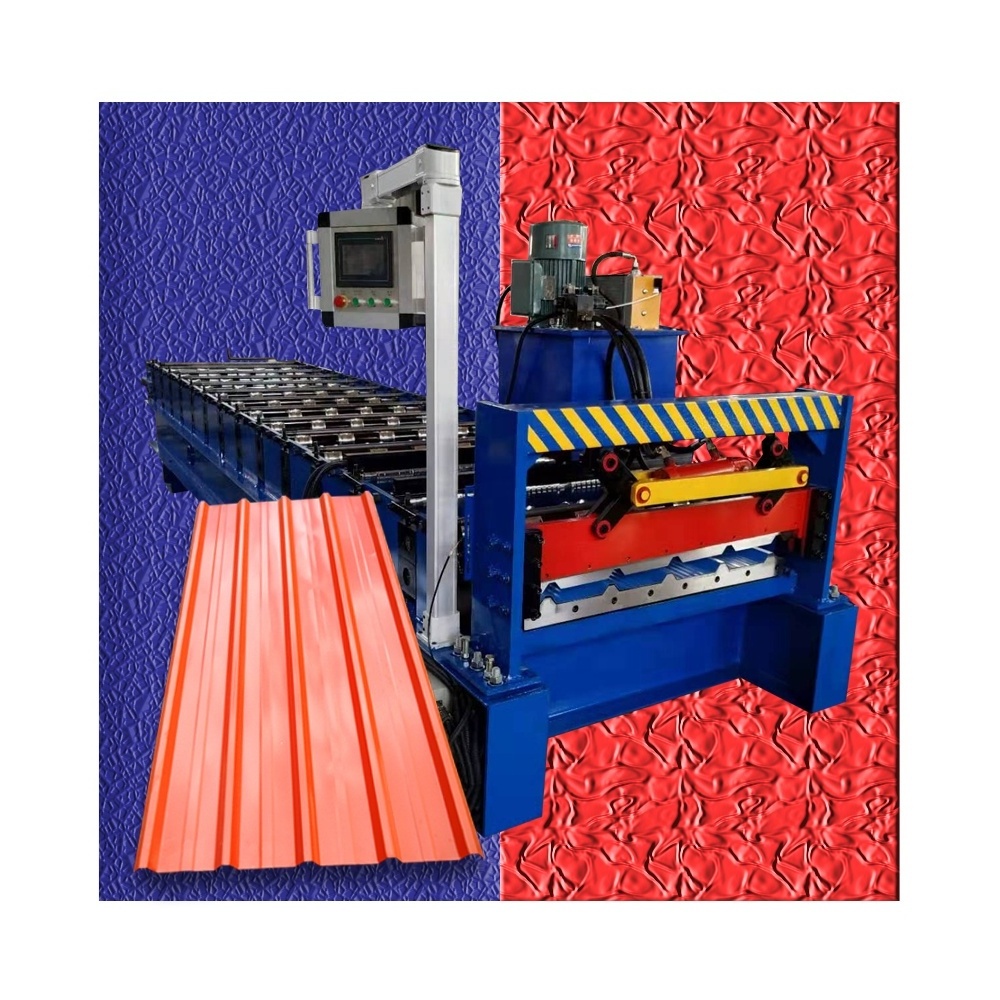

PV4 PV6 Metal roofing machine high rib roll forming machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX high rib roll forming machine

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7500*1700*1600Mm

-

Weight:

-

5 kg

-

Raw material:

-

Galvanized Steel Sheet

-

Color:

-

Customers Requirement

-

Usage:

-

Roof Tile Panel

-

Product name:

-

high rib roll forming machine

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# St

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Material:

-

Color Steel Galvanized Plate

-

Name:

-

PV4 PV6 Metal roofing machine high rib roll forming machine

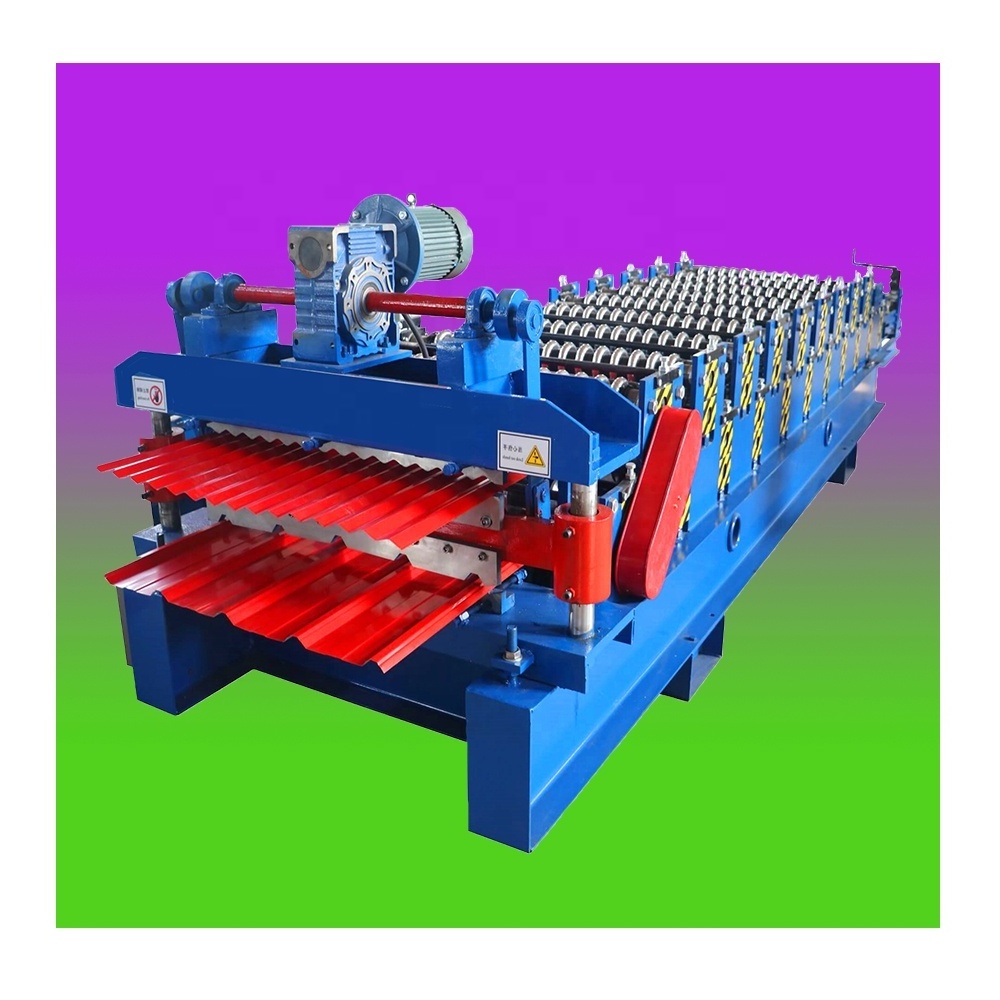

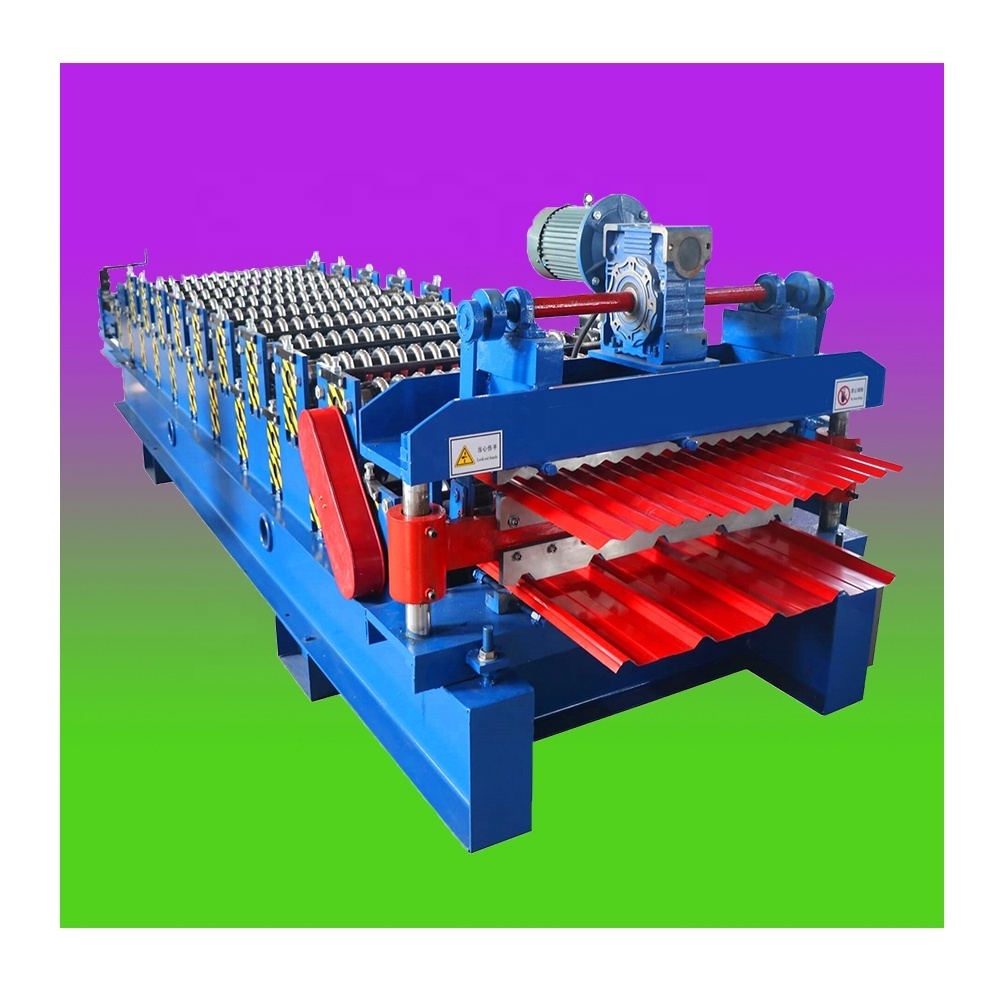

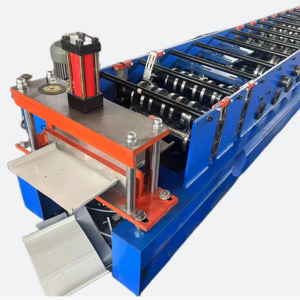

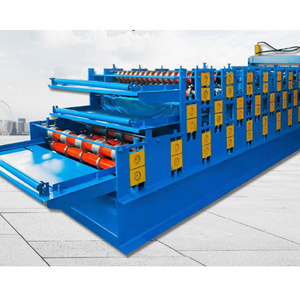

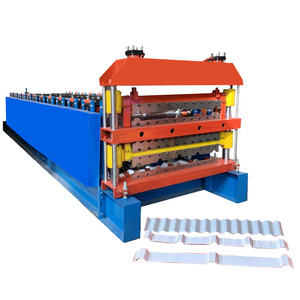

Metal roofing machine high rib PV4 PV6 roll forming machine

1.What's component of high rib roll forming machine?

high rib roll forming machine consists of uncoiler and its base,infeed guides,fixed position driven forming stations,pressing die,shearing device,hydraulic station,PLC control console and so on.Our company has dozens of profile models for this series roll forming machine,We can design different kinds of profile and fittings for machine,as per customers’ requirement.

|

1 set of manual decoiler

|

Un-powered;

Single head;

|

|

1 set of main roll forming machines

|

Steps: 16

Roller Material: 45# steel

Line speed: 12m/min;

|

|

1 set of computer control cabinet

|

It adopts Taida PLC to control. The target piece length is adjustable and digit of it can be adjusted. It contains transducer, which can ensure the accuracy of length is ± 1mm. 5.7 inch touch screen, easy to operate Computed mode has two modes: Automatic and manual one. |

|

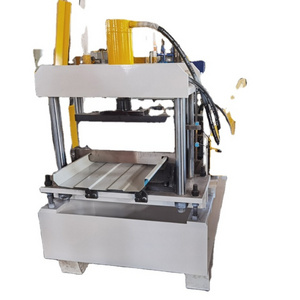

1 set of hydraulic System

|

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

|

|

1 set of cutting mechanism

|

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products.

|

|

1 set of counter

|

One counter gauges length, pulses, and decides length |

|

1 set of output table

|

It used to load the finished products |

2.What's sketch of high rib roll forming machine?

Decoiling→Feeding & Guiding→Roll Forming→ Cutting→Finished Products To Support Table

What is panel for high rib roll forming machine?

high rib roll forming machine details

The following is our high rib roll forming machine rollers and machine assembly at site.

Related machinery

1.Different types roof profile drawing forming machine ;

2.Curve roof roll forming machine ; 3.Ridge cap roll forming machine ;

4.Floor deck roll forming machine ; 5.Rain gutter roll forming machine ;

6.Down pipe roll forming machine ; 7.Highway guardrail roll forming machine ;

8.Roller shutter door forming machine ; 9.Door frame roll forming machine ;

10.CZU purlin roll forming machine ; 11.Light keel roll forming machine ;

12.Slitting machine (lines); 13.Shearing/bending machine ;

14.Decoiler(Hydraulic decoiler ,electric decoiler and manual decoils) and so on .

What are the contact methods you could get in touch with us?

About the high rib roll forming machine,If you have any need and questions ,please don't hesitate to contact us . Alice at here 12 hours waiting for you . Looking forward to you join us !

| Contact Person | Alice |

| Whatsapp/Wechat | 008618920411229 |

| Skype | haixing18920411229 |