- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

110*700*1580mm

-

Weight (KG):

-

900

-

Rebar diameter:

-

16-32mm

-

Application in:

-

Forging Industry

-

Max. power:

-

30MPa

-

OEM/ODM:

-

Acception

-

Upsetting speed:

-

1/10-15s

-

Packing size:

-

1320*700*1550mm

-

Packing weight:

-

920kg

-

The hydralic oil:

-

46/68# anti-wear

-

Enlarge:

-

15%-20%

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XUGONG

-

Machine Type:

-

AUTO

-

Voltage:

-

220V/380V/440V

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

110*700*1580mm

-

Weight (KG):

-

900

-

Rebar diameter:

-

16-32mm

-

Application in:

-

Forging Industry

-

Max. power:

-

30MPa

-

OEM/ODM:

-

Acception

-

Upsetting speed:

-

1/10-15s

-

Packing size:

-

1320*700*1550mm

-

Packing weight:

-

920kg

-

The hydralic oil:

-

46/68# anti-wear

-

Enlarge:

-

15%-20%

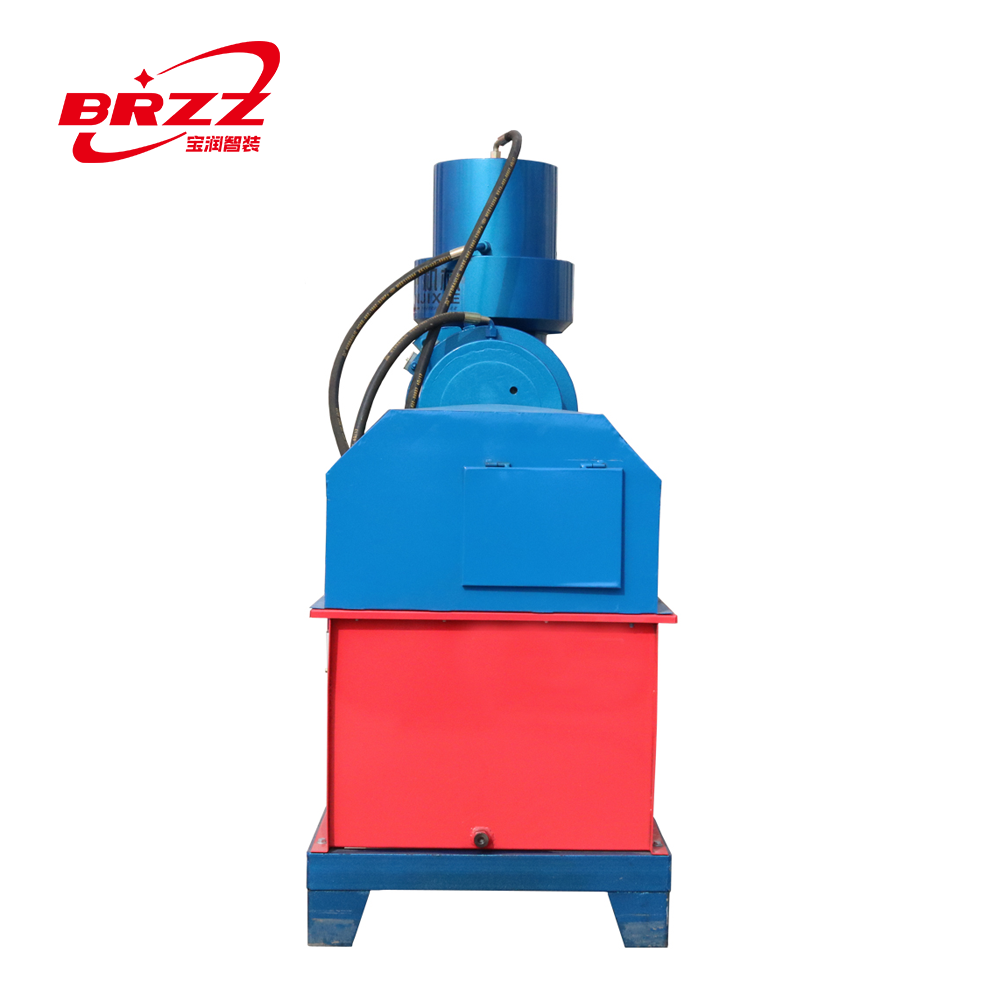

Rebar upsetting machine (double cylinders full automatic)

Reinforced upsetting technology uses the principle of cold heading to plastically deform the end of the bar, increase the diameter by about 4mm, and then machine the thread. Make the processed steel bar section larger than the original bar section, greatly improving the tensile strength of the joint. This upset threaded joint is completely broken off from the base material by a tensile test and is suitable for projects requiring a high connection strength.

Main Features

1. Equipment failure rate is small,non-fragile parts construction costs low.

2.Simple operation,hydraulic electrical control,do not need professional technicians training,ten minutes to boot operation.

3. Extend the cross-sectional area of the reinforcing bar end by 15%-20% so that the bottom diameter of the processed thread is not less than the diameter of the reinforcing bar base metal, and the tensile strength of the steel bar can be 100%.

4. High production efficiency, upsetting a rebar head in 10-15 seconds.

5.Processing a wide range of steel,which can be processed in line with GB1499, GB13014 standard Φ16-Φ32mm,various specifications of the steel.

6. Lightweight, generous appearance, fast speed, flexible use, etc.

7.Environmental protection,security,it is not subject to environmental and climates changes.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

Henan Baorun Machinery Co., Ltd. is a joint-stock company, founded in 2010, which is located NO 18, SenYuan West road of Changge City, Henan Province.

Henan Baorun Machinery Co., Ltd. is a set of engineering machinery, construction machinery, profiles of cold machinery and pre-application equipment, rubber parts R & D, manufacturing and sales of specialized production enterprises.

The main products are as following:

spraying machine, injection pump, bending machine, upsetting machines, threading machine, bending machine, bender machines, flange machines.

Please contact me for more details about price discount, delivery time and packing!

Web: www.hnbrjx.cn

http:// hnbrjx.en.alibaba.com