- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

300~900mm

-

Standard of flange:

-

JIS Standard

Quick Details

-

Standard:

-

bs, GB, JIS

-

Place of Origin:

-

China

-

Brand Name:

-

BSC

-

Model Number:

-

300~900mm

-

Standard of flange:

-

JIS Standard

|

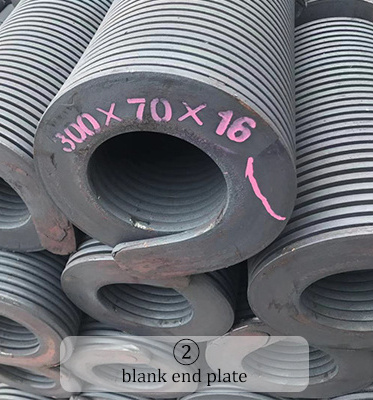

Product Name

|

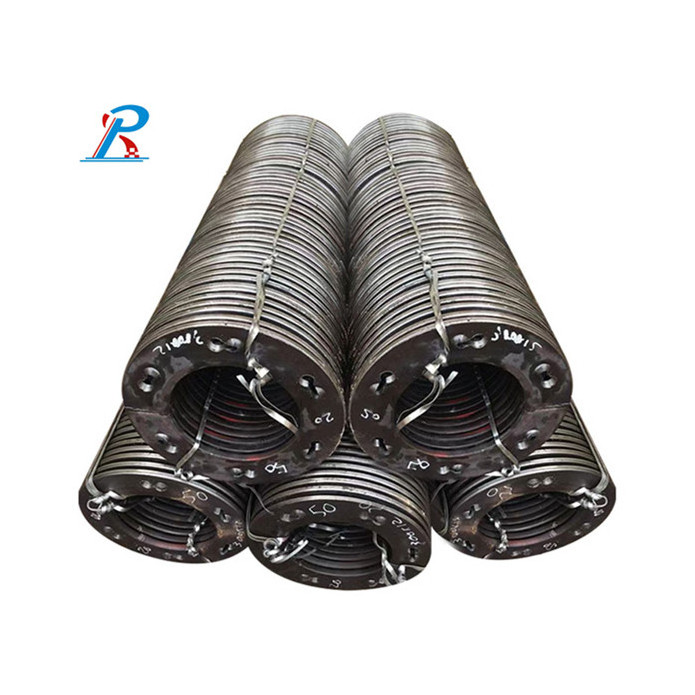

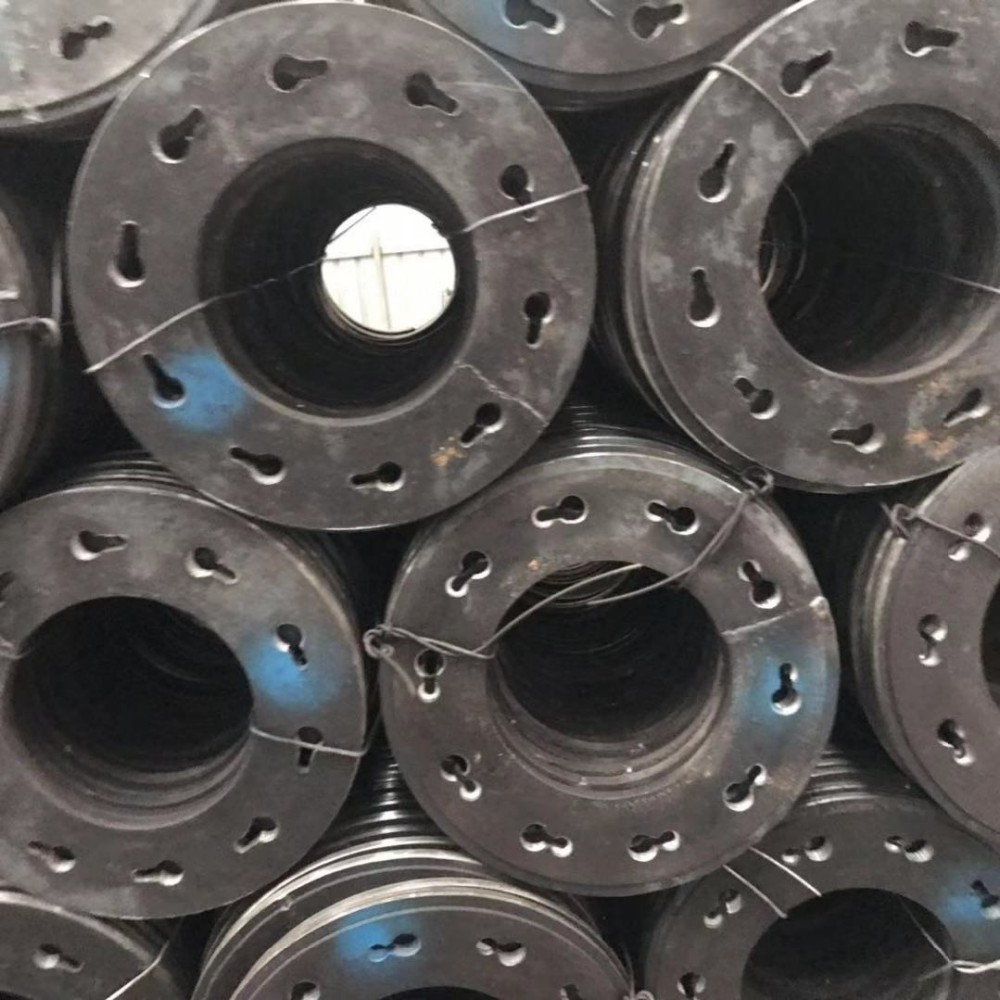

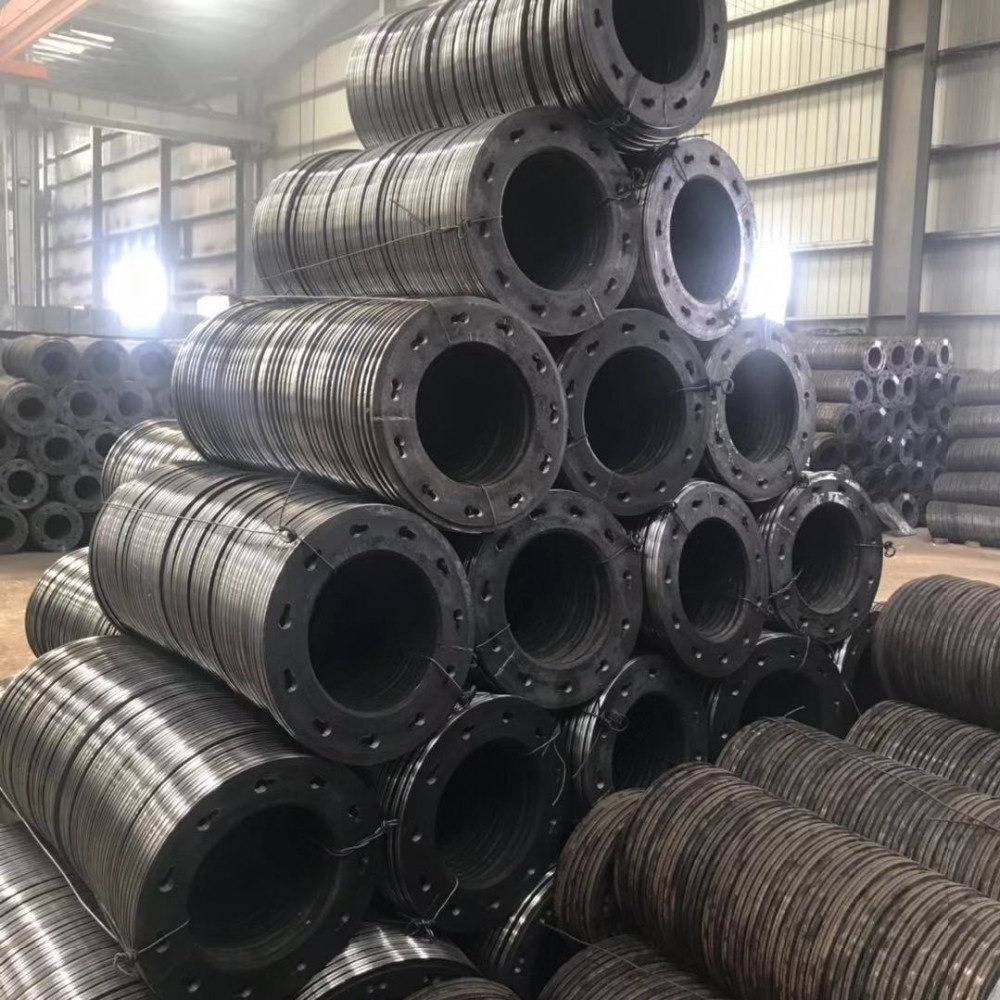

Steel end plate of phc pile mould

|

|

|

||

|

Material

|

Q235/SS400

|

|

|

||

|

Out Diameter

|

300, 350, 400, 450, 500, 600, 700, 800, 1000 (mm)

|

|

|

||

|

Inner Diameter

|

180, 210, 220, 240, 300, 350, 400, 500, 560, 580, 700(mm)

|

|

|

||

|

Thickness

|

10, 12, 14, 16, 18, 19, 20, 22, 24, 28(mm)

|

|

|

||

|

Holes

|

6, 7, 8, 9, 10, 12, 16, 18, 20, 24, 36(holes)

|

|

|

||

|

Techique

|

1hot rolled 2cutting 3welding 4drill hloes

|

|

|

||

|

Remark

|

We can also produce as customers’ special request.

|

|

|

||

|

Application

|

Concrete pile of highway, bridge, port, buildings, industrial workshop and power plant.

|

|

|

||

Product performance description:

Full-automatic Rolling welder

Pipe Pile Moulding Centrifuge

Drilling machine of endplate pile

Full-automatic shirt board slitting machine

Steel end plate of PHC pile mould

PC bar

Q:Do you have set up an independent factory?

A:

We have our own factory.

Q: What can you do for us?

A:

1. Before sales can be targeted to give some constructive Suggestions.

2.Make a specific plan for your needs.

3. After sales reference specific products, different products have different services. Refer to the specific product description.

Q: Can you do the basic design for us?

A:

Yes, we have a professional team with rich experience in basic design of cement pipe making equipment with CAD software. You just need to tell us your ideas and requirements, and we will provide you with the most perfect design.