- Product Details

- {{item.text}}

Quick Details

-

Production Capacity (kg/h):

-

800 - 17000 kg/h

-

Brand Name:

-

Derui Brand

-

Voltage:

-

380V/50Hz/3Phase

-

Dimension(L*W*H):

-

based on models

-

Power (kW):

-

55

-

Weight (T):

-

9.5

-

Product name:

-

Twin Shaft Shredder

-

Blades material:

-

55SiCr/SKD11/H13

-

Crushing material:

-

waste metal rubber plastics

-

Final product:

-

Small Scraps

Quick Details

-

Max.Production Capacity (kg/h):

-

17000

-

Place of Origin:

-

Henan, China

-

Machine Type:

-

Double shaft shredder

-

Production Capacity (kg/h):

-

800 - 17000 kg/h

-

Brand Name:

-

Derui Brand

-

Voltage:

-

380V/50Hz/3Phase

-

Dimension(L*W*H):

-

based on models

-

Power (kW):

-

55

-

Weight (T):

-

9.5

-

Product name:

-

Twin Shaft Shredder

-

Blades material:

-

55SiCr/SKD11/H13

-

Crushing material:

-

waste metal rubber plastics

-

Final product:

-

Small Scraps

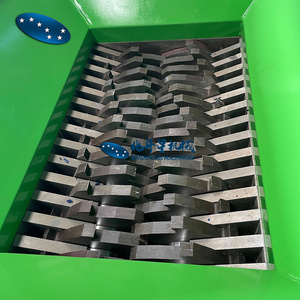

Heavy Duty Double Shaft Shredder

Description:

Twin-shaft shredder also named shearing machine, by cutting, tearing and extruting to reduce the materials’ size, widely used in area of waste plastic, waste rubber, wood, crop straw, automobile recycling …etc, this is a quality and reliable equipment in recycling business.

Our scrap shredder can process materials as below:

- toxic hazardous industrial waste

- industrial waste

- solid urban waste

- bulky waste

- electronic equipment waste

- refrigerator recycling

- waste tires

- plastic recycling

- glas and rock wool

- paper shredding recycling

- hospital waste

- oil filter recycling

- Garbage

- Wood Pallet

Features of this scrap car shredder

Shredding room adopt large thickness, high strength, wear resistance of steel. The whole crushing room was finished by CNC machine, with high precision, easy disassembly, repair, maintenance, long life and other advantages.

The knives use imported high-quality alloy steel, with high strength, good toughness, not easy to break and so on. And to ensure that there is a good blade work, disassembly, and easy to maintenance.

Screen using high-strength material processing, with high strength, long service life, and easy to operate.

|

Model |

Dimensions(mm) |

Crushing chamber size(mm) |

Blade diameter (mm) |

Blade thickness (mm) |

Blade number (mm) |

Power(kw) |

Weight(kg) |

|

DR-600 |

2800×1300×1850 |

500×480 |

200 |

20 |

24 |

11×2 |

2200 |

|

DR-800 |

3000×1300×1850 |

800×480 |

200 |

20 |

40 |

22×2 |

2500 |

|

DR-1000 |

3300×1900×2200 |

1000×690 |

300 |

40 |

24 |

30×2 |

5200 |

|

DR-1200 |

3600×2000×2200 |

1200×690 |

300 |

40 |

30 |

37×2 |

6400 |

|

DR- 1500 |

4180×2100×2400 |

1500×850 |

550 |

50/75 |

30/20 |

45×2 |

9000 |

|

DR-1800 |

5800×2400×3300 |

1800×1206 |

550 |

50/75 |

36/24 |

50×2 |

13600 |

|

DR-2000 |

6400×2700×3500 |

2000×1490 |

600 |

50/75 |

40/26 |

90×2 |

20100 |

|

DR-2500 |

7500×3200×3800 |

2500×1800 |

600 |

75/100 |

32/24 |

110×2 |

25000 |

|

DR-3000 |

8600×3500×4000 |

3000×1800 |

600 |

75/100 |

40/30 |

132×2 |

31000 |

Firstly ------ Your raw material information

I will provide you the most suitable metal shredder machine according to your raw material information. Such as I need to know your raw material; your production capacity; your final product's requirements.

Secondly ------ Guidance

If customers plan to visit my factory, I will pick customers up at the airport, and then accompany with customers to test shredders in my factory. We can comminucate the most suitable machines' Commercial Invoice in my factory, and do the cooperation.

Thirdly ------ After-sale service 1

My factory will prepare shredders after receiving the down payment. Normally, after 5-25days preparing time, my factory will finish the machines' preparing, and then test machines for you, and I will send the testing effect to customers. Then after customers are satisfied with the testing effect, then customers will plan to send the down payment to my factory, then we load machines for customers.

Finally ------ After-sale service 2

After customers receiving the machines, my factory will dispatch technicians to install machines for customers, and teach customers how to operate machines.

1) Are you a factory or trade company?

We are professional recycling shredder factory with the modernized management and quality control system, experienced production team, advanced manufacturing and processing facility. Export proportion around 50%. .

2) How can I trust your company?

a. modernized management and quality control system, experienced production team, advanced manufacturing and processing facility.

b. Welcome to inspect anytime.

c. About the machine, we do much better on: Wear plates, seals, structure design, pressure head.

3) How about the garbage bag shredder test running & installation?

Before the order, welcome you to come to testing all machines in our factory, we have ready machines all the time. Before shipping out your machines, we will invite you to come to test your machines, when you are satisfied; we start to pack and delivery.

4) Any warranty?

Under the proper usage, 1year for whole garbage bag shredder.

5) Is your price competitive?

Only good quality machine we supply. Surely we will give you best factory price based on superior product and service.